Combined type lifting induction heating disassembling-assembling machine

A technology of induction heating, disassembly and assembly machine, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, imperfection, difficult work, etc., and achieve the effect of high work efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

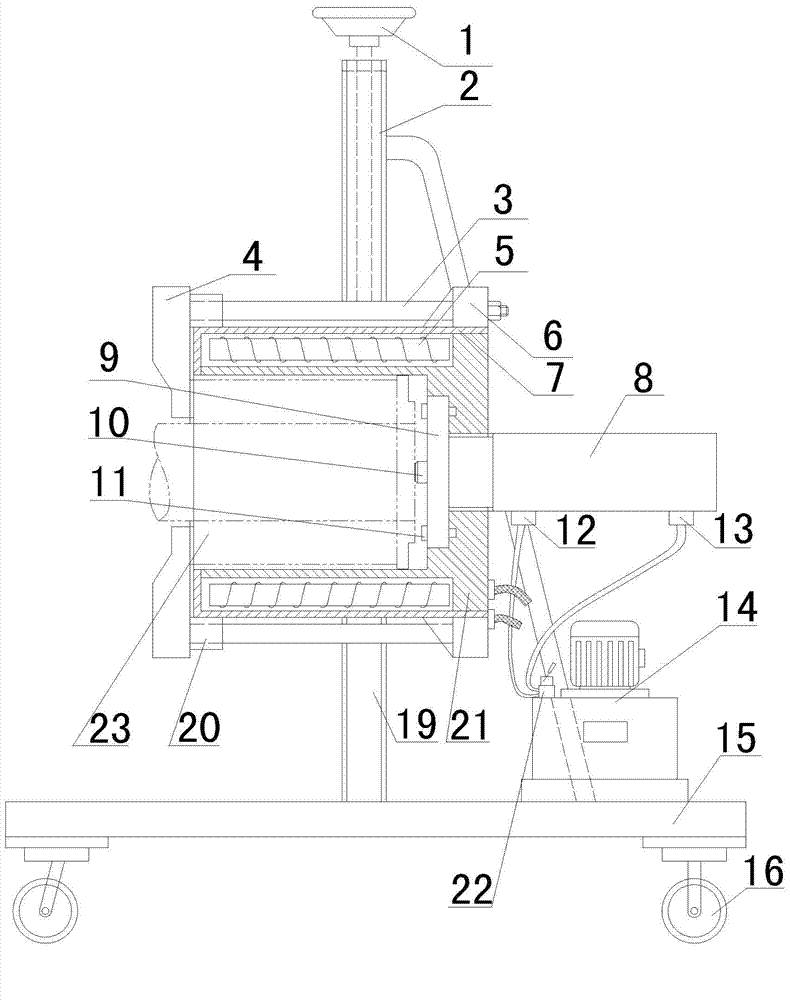

[0016] Such as figure 1 As shown, the combined lifting induction heating disassembly machine includes a hydraulic top pulling device, a control device and a lifting adjustment device. The lifting adjustment device includes a vehicle frame 19 and an adjustment screw 2. The upper end of the adjustment screw 2 is provided with a handwheel 1, The hydraulic jacking device is connected with the vehicle frame 19 through the adjusting screw mandrel 2 . The hydraulic jacking device includes a hydraulic jack 8, a pull rod 3, a pull hook 4, and an inner casing 21. The pull hook 4 is connected with the pull rod 3 through a positioning sleeve 20, and the pull rod 3 is connected with the inner casing 21 through a pull rod support sleeve 6.

[0017] The inner casing 21 is set as a hollow cylindrical structure, the hydraulic jack 8 is connected and fixed to the inner casing 21, and the piston rod 10 of the hydraulic jack 8 extends into the cavity of the inner casing 21 for accommodating the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com