Closed dustproof light brick cutting machine

A brick cutting machine, lightweight technology, applied in stone processing tools, work accessories, manufacturing tools and other directions, can solve the problems of difficult adjustment, inconvenient movement, etc., to achieve the effect of less human harm, simple structure and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

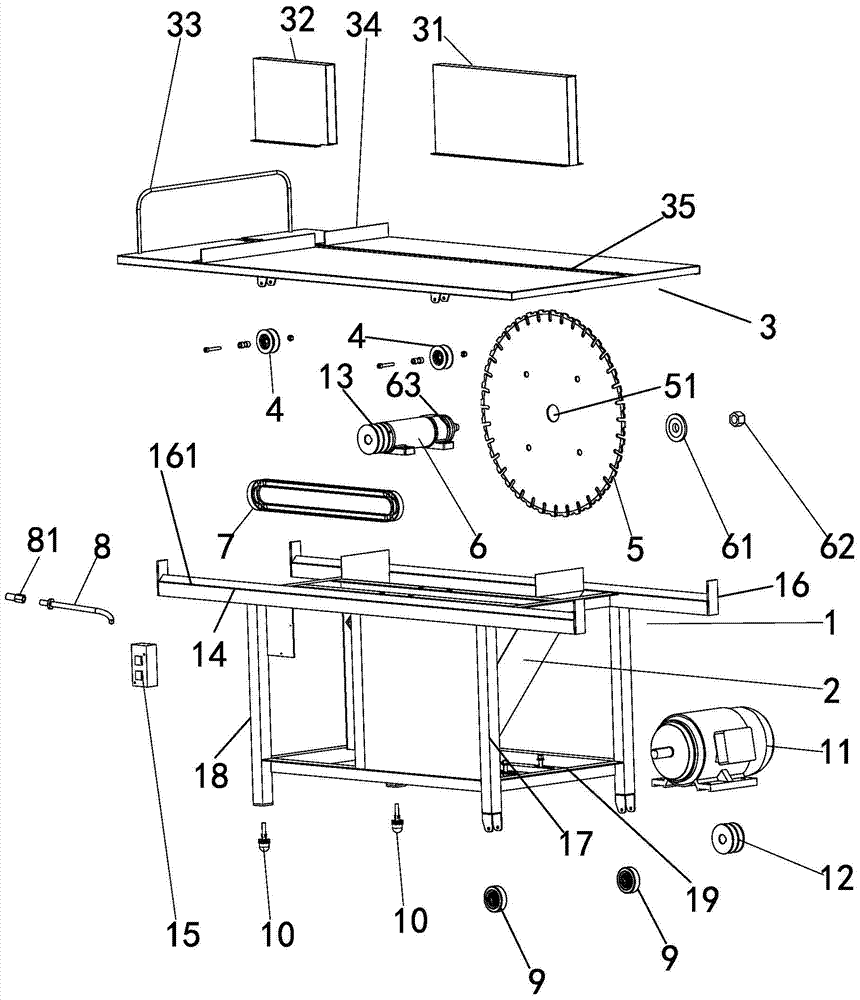

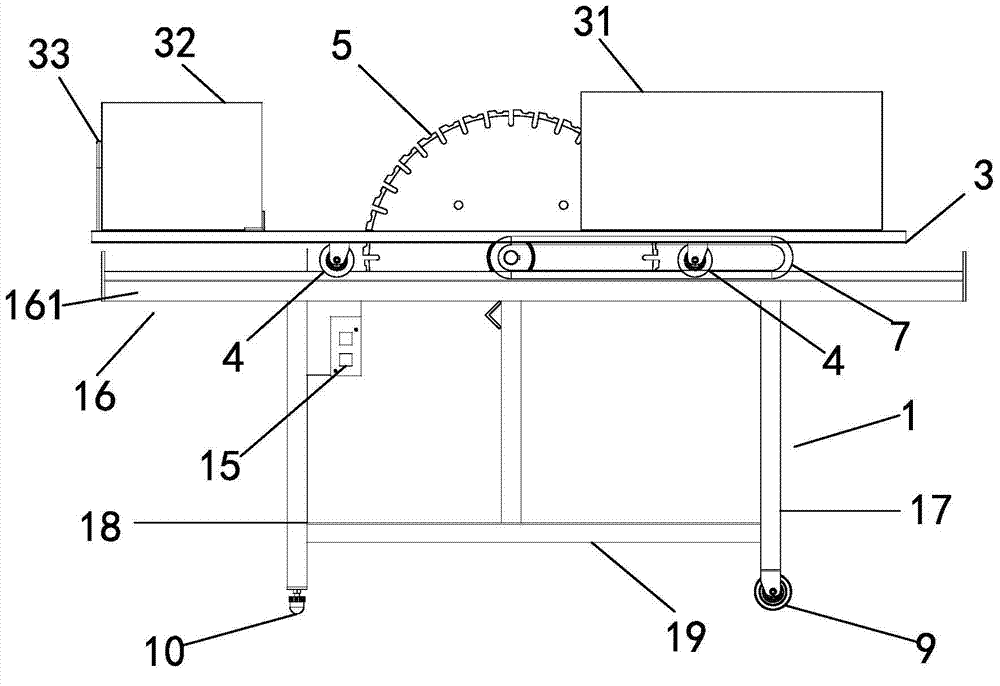

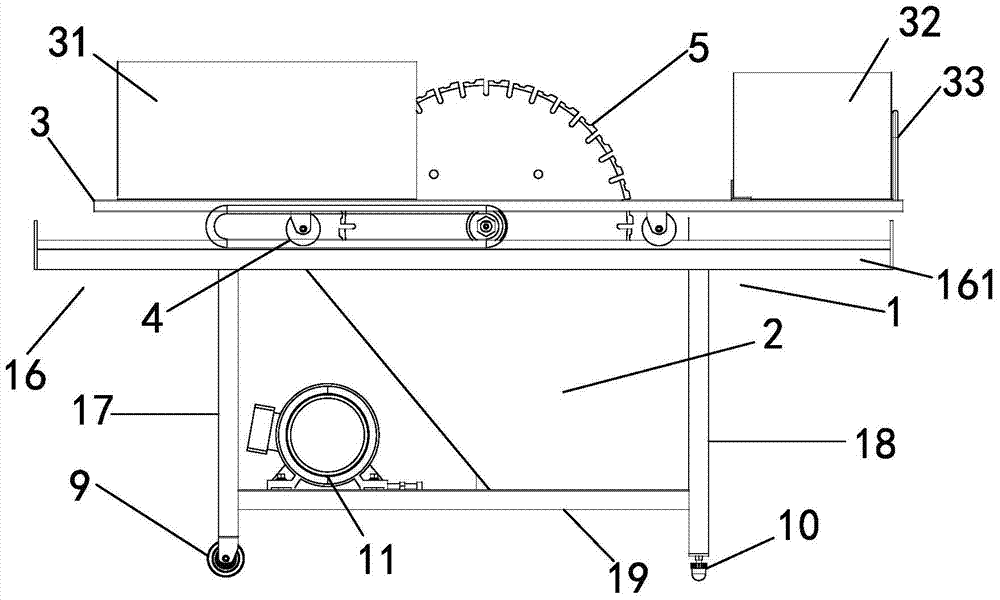

[0025] Such as Figure 1 to Figure 7 Shown, a kind of closed dust-proof lightweight brick cutting machine comprises machine base 1, workbench 3 and blade 5, and machine base 1 includes support 16 and support foot, and support 16 is connected to the upper end of support foot. The supporting legs include two first supporting legs 17 and two second supporting legs 18 , the lower ends of the first supporting legs 17 are connected with moving rollers 9 , and the moving rollers 9 are connected to the first supporting legs 17 by means of bolts. The mobile roller 9 is convenient for the operator to move the cutting machine, so that the cutting machine has a wider application range and stronger flexibility. The lower end of the second leg 18 is provided with a screw hole, and an adjusting bolt 10 is connected in the screw hole. The adjusting bolt 10 is rotatable, and the height of the second leg 18 can be changed after rotation. Adjusting bolt 10 can adjust the height position of cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com