Raw material commixed polypropylene multilayered co-extrusion transfusion film and production method thereof

A multi-layer co-extrusion and infusion film technology, which is applied in the direction of layered products, chemical instruments and methods, and synthetic resin layered products, can solve problems such as poor softness, uneven thickness, and unstable weighing, and achieve Ensure the safety of life and save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

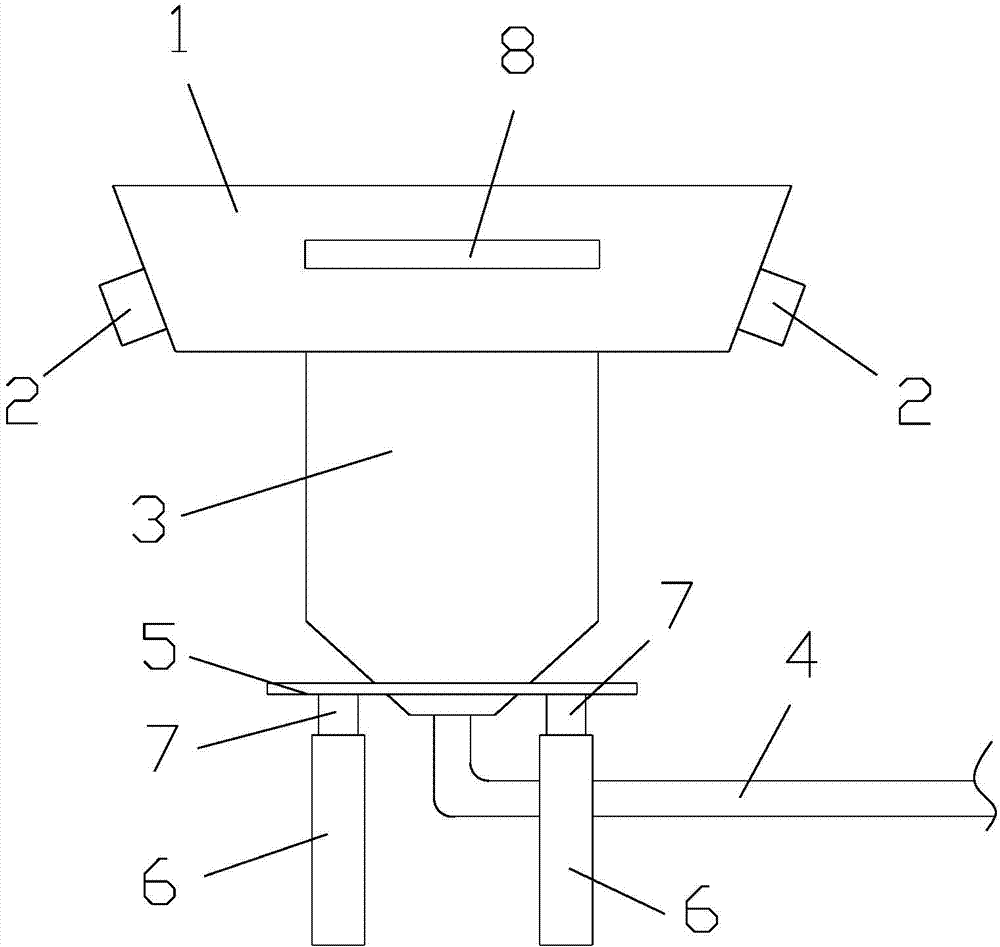

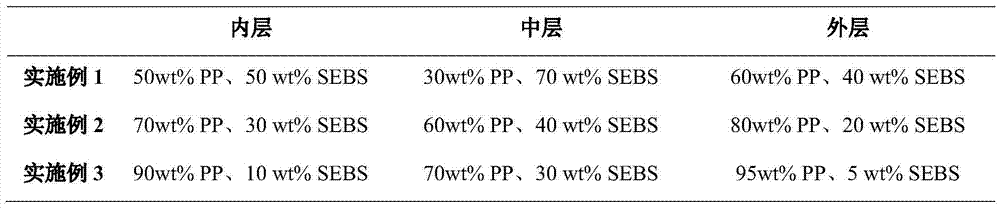

[0028] A production method of a raw material blended polypropylene multilayer co-extrusion infusion film, the polypropylene multilayer coextrusion infusion film sequentially comprises a three-layer structure, successively an inner layer, a middle layer and an outer layer, the steps of the production method as follows:

[0029] (1) Inhale the various plastic raw materials of each layer into the hopper of the weighing mixer, fall into the weighing pan of the weighing (or loss-in-weight) mixing machine according to the set ratio, and weigh them;

[0030] (2) After weighing, open the weighing pan, drop into the mixing tank and stir, the mixing amount is not less than 20kg / hour, and the mixing time is not less than 10s;

[0031] (3) The lower end of the mixing barrel is directly connected to the screw part of the single-screw extruder, and the mixed materials of each layer enter the three single-screw extruders respectively, and enter the die head through the barrel, the filter dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com