A small spring-type refueling port door for a heavy-duty truck fuel tank

A heavy-duty truck, spring-type technology, applied in the field of fuel filler, can solve the problems of non-elastic deformation spring leaf failure, splashing, affecting service life, etc., achieve the effect of smooth automatic reset process, increase the speed of filling, and smooth air discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

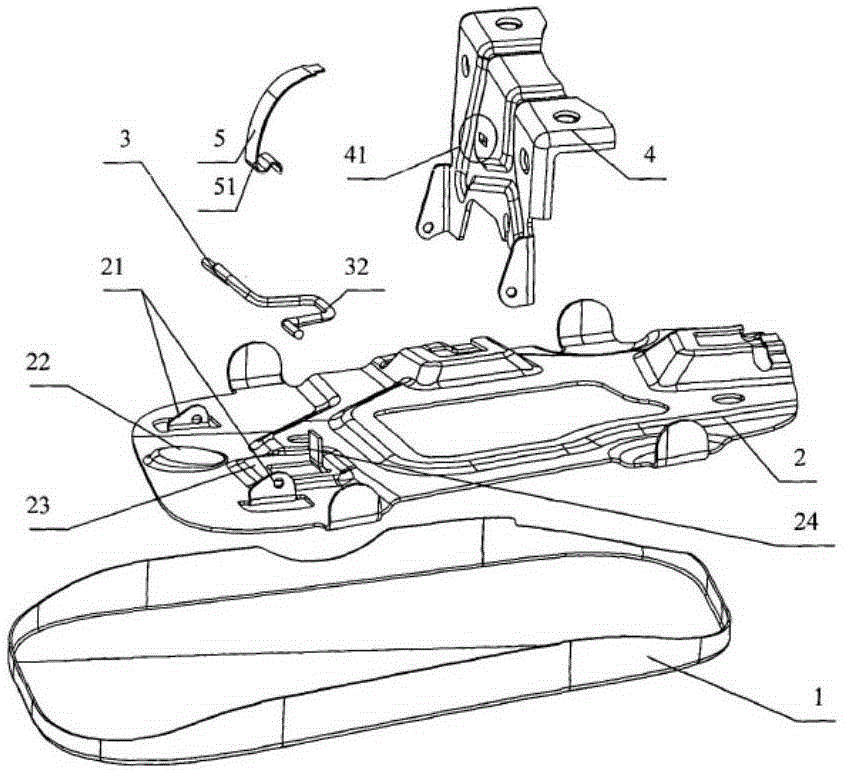

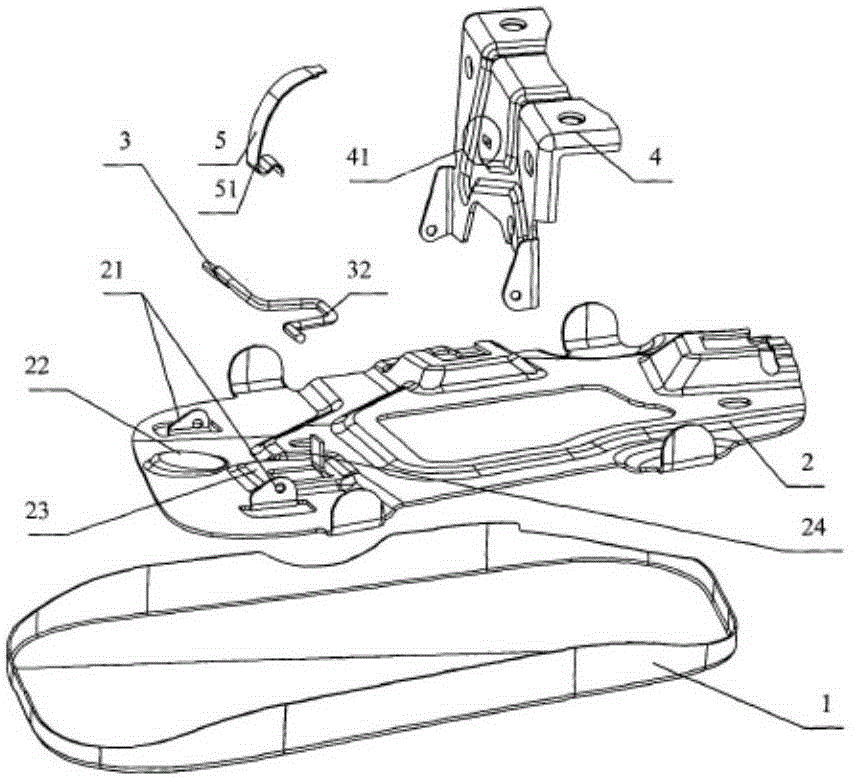

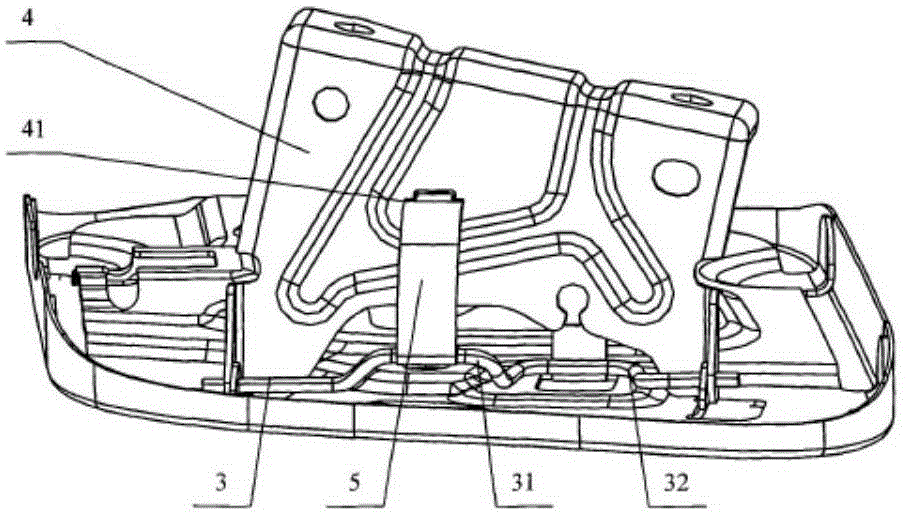

[0040] Such as Figure 7 to Figure 9 As shown, the spring type refueling port wicket of the heavy truck fuel tank of the present invention comprises a door panel 2, an inner cover 5, a spring 4, a pin shaft 3, a chain 1, a breathing hole 6 and a chain fixing hole 7; wherein:

[0041] One end of the door panel 2 is provided with a first pin support hole, and one end of the inner cover 5 is provided with a second pin support hole, and the door panel 2 is formed by a pin 3 and the inner cover 5 so that 3 Connect in the way of free rotation;

[0042] The inner cover 5 is fixed on the fuel tank body (not shown in the figure) by screws;

[0043] A spring 4 is sleeved on the pin shaft 3;

[0044] One end of the spring 4 is L-shaped, which is directly supported on the bottom of the inner cover; the other end of the spring 4 is U-shaped, and this end passes through the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com