Method and device for preparing hydrogen fluoride through low-grade superfine fluorite powder

A low-grade technology of fluorite powder, which is applied in the field of equipment to realize the method, can solve the problems of blockage of air ducts, reduction of heat transfer efficiency, and crusting of reactors, so as to prevent pipe blockage, improve heat transfer efficiency, and prevent condensation shell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

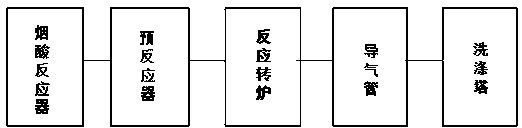

[0029] Including the following steps:

[0030] A. mixed acid step, 98 acids and 105 acids are added in proportion to the nicotinic acid reactor and mixed, and the mass ratio of the 98 acids and 105 acids is 1:0.8;

[0031] b. Pre-reaction step, the calcium fluoride content is 93%, the fluorite powder with a particle size of 300 meshes and the sulfuric acid from the nicotinic acid reactor after the mixed acid step are sent to the pre-reactor according to the conventional ratio for pre-reaction, in the pre-reactor The steam temperature is 170°C;

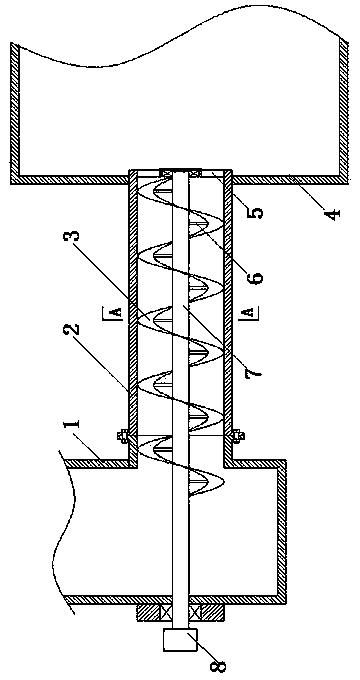

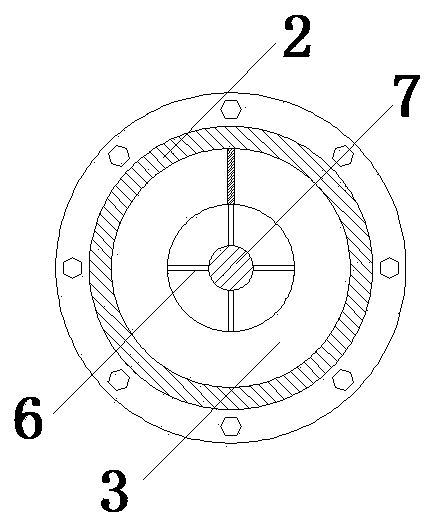

[0032] c. Reaction step, send the fluorite powder processed by the above steps together with sulfuric acid and hydrogen fluoride into the reaction converter, and under the action of the spiral crushing device in the reaction converter, it will continuously exchange heat with the inner wall of the converter at 380°C and complete the reaction. After the conversion rate of calcium fluoride reaches 97%, the fluorine gypsum is sent to the ...

Embodiment 2

[0035] Including the following steps:

[0036] A. mixed acid step, 98 acids and 105 acids are added in proportion to the nicotinic acid reactor and mixed, and the mass ratio of the 98 acids and 105 acids is 1:1.5;

[0037] b. The pre-reaction step, the calcium fluoride content 91%, the fluorite powder with a particle size of 400 mesh and the sulfuric acid from the nicotinic acid reactor after the mixed acid step are sent to the pre-reactor according to the conventional ratio for pre-reaction. In the pre-reactor Steam temperature is 175°C;

[0038] c. Reaction step, send the fluorite powder processed by the above steps together with sulfuric acid and hydrogen fluoride into the reaction converter, and under the action of the spiral crushing device in the reaction converter, it will continuously exchange heat with the inner wall of the converter at 390°C and complete the reaction. After the conversion rate of calcium fluoride reaches 97%, the fluorine gypsum is sent to the gypsu...

Embodiment 3

[0041] Including the following steps:

[0042] A. mixed acid step, 98 acids and 105 acids are added in proportion to the nicotinic acid reactor and mixed, and the mass ratio of the 98 acids and 105 acids is 1:2;

[0043] b. Pre-reaction step, the calcium fluoride content is 90%, the fluorite powder with a particle size of 500 mesh and the sulfuric acid from the nicotinic acid reactor after the mixed acid step are sent to the pre-reactor according to the conventional ratio for pre-reaction. Steam temperature is 180°C;

[0044] c. Reaction step, send the fluorite powder processed by the above steps together with sulfuric acid and hydrogen fluoride into the reaction converter, and under the action of the spiral crushing device in the reaction converter, it will continuously exchange heat with the inner wall of the converter at 400°C and complete the reaction. After the conversion rate of calcium fluoride reaches 97%, the fluorine gypsum is sent to the gypsum tank, and the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com