Multistage gas stripping and separating integrated anaerobic treatment device

The technology of an anaerobic treatment device and a gas-liquid separation tank, which is applied in the direction of anaerobic digestion and treatment, can solve the problems such as the influence of the service life of the gas-water separation tank, poor gas-liquid separation effect and efficiency, and impact on the inner wall of the gas-water separation tank. Achieve the effects of saving construction and land occupation costs, convenient operation, and fast gas-liquid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

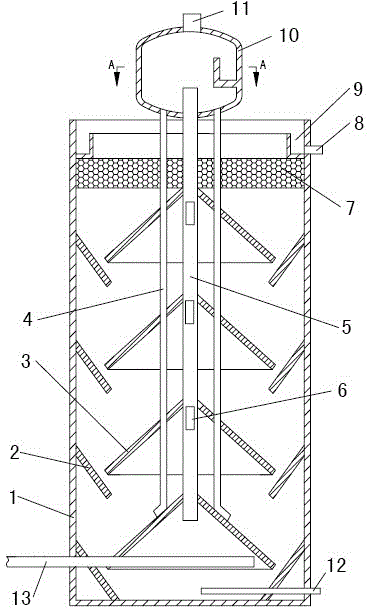

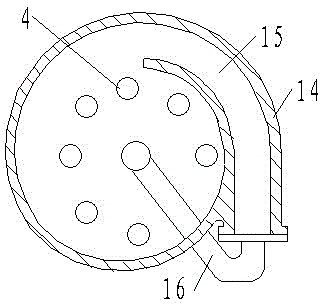

[0012] Such as figure 1 As shown, the multi-stage gas lift and separation integrated anaerobic treatment device of the present invention mainly includes a tank body 1 and a gas-liquid separation tank 10 , and the gas-liquid separation tank 10 is arranged on the top of the tank body 1 . The tank body 1 adopts a steel structure, the whole structure is columnar, and the upper end is open, and there are more than two sludge expansion gas lift areas ( figure 1 There are four in the middle picture, the number can be set according to specific requirements), and an anaerobic reaction zone is formed between the upper and lower sludge expansion and stripping zones. The sludge expansion airlift area is formed by an upwardly open falling bucket 2 and a downwardly open conical cover 3 arranged oppositely. The falling bucket 2 is arranged outside the conical cover 3 and fixed on the inner wall of the pool body 1. An upflow slot for the passage of muddy water is arranged between the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com