Thermosetting composition, curing film and filter

A composition and thermosetting technology, applied in the field of thermosetting compositions, can solve the problems of limited compatibility and solubility, low solubility of bisphenol fluorene type epoxy compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (production of thermosetting composition)

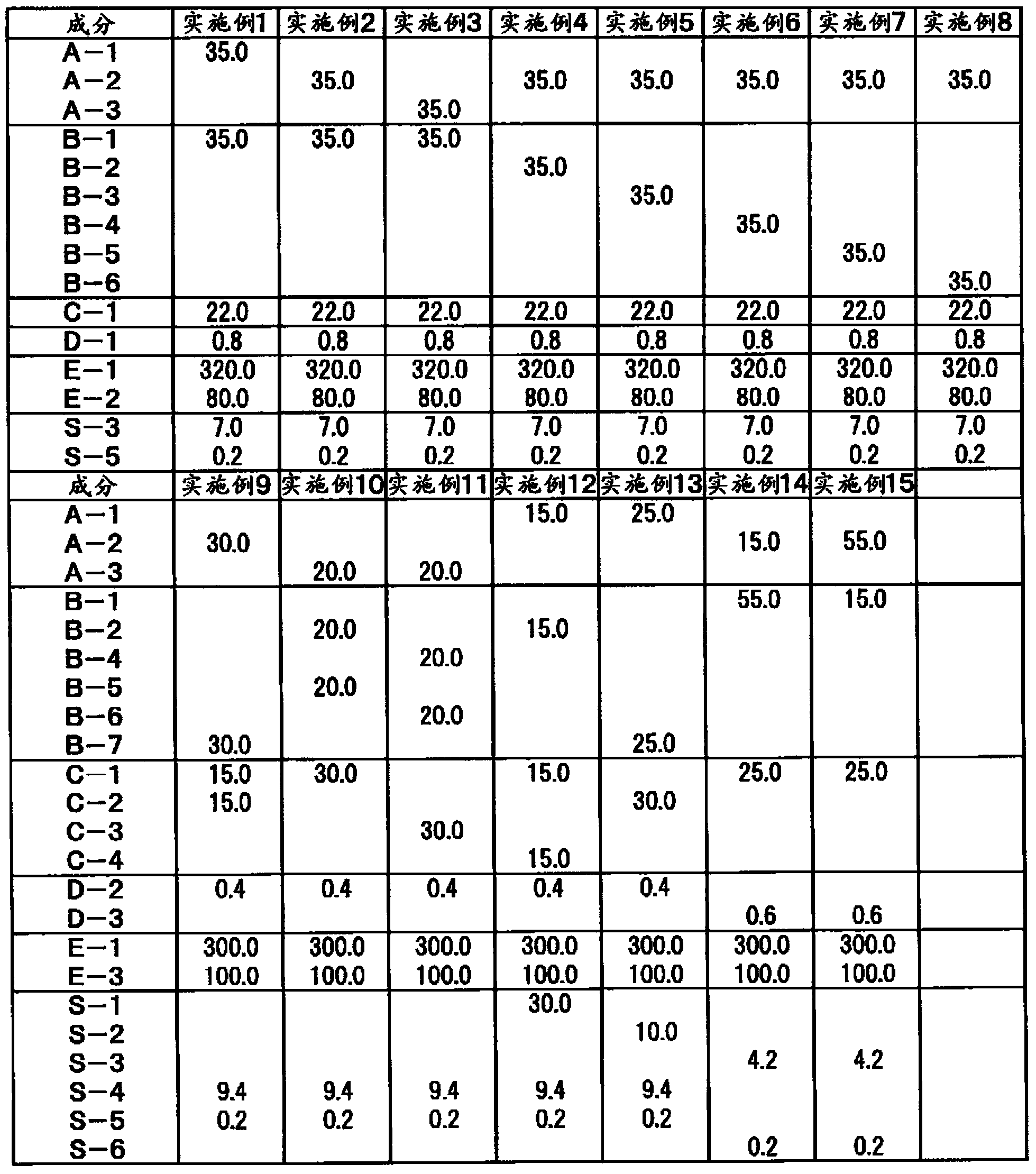

[0047] The mixture was blended according to the composition shown in Table 1, and stirred and mixed at room temperature for 3 hours to dissolve the solid content in the solvent to prepare a thermosetting composition. The numerical value of a composition is mass parts, and it describes so that the total of solid content may become 100 mass parts. Among the solid components, there are also components that are synthesized in the state of being dissolved in a solvent (propylene glycol monomethyl ether acetate) from the beginning, but in this case, the numerical value of the composition indicates the solvent carried in as a mass part of the solid content Components are described as parts by mass contained in the solvent. Components used in the compounding of the examples are as follows.

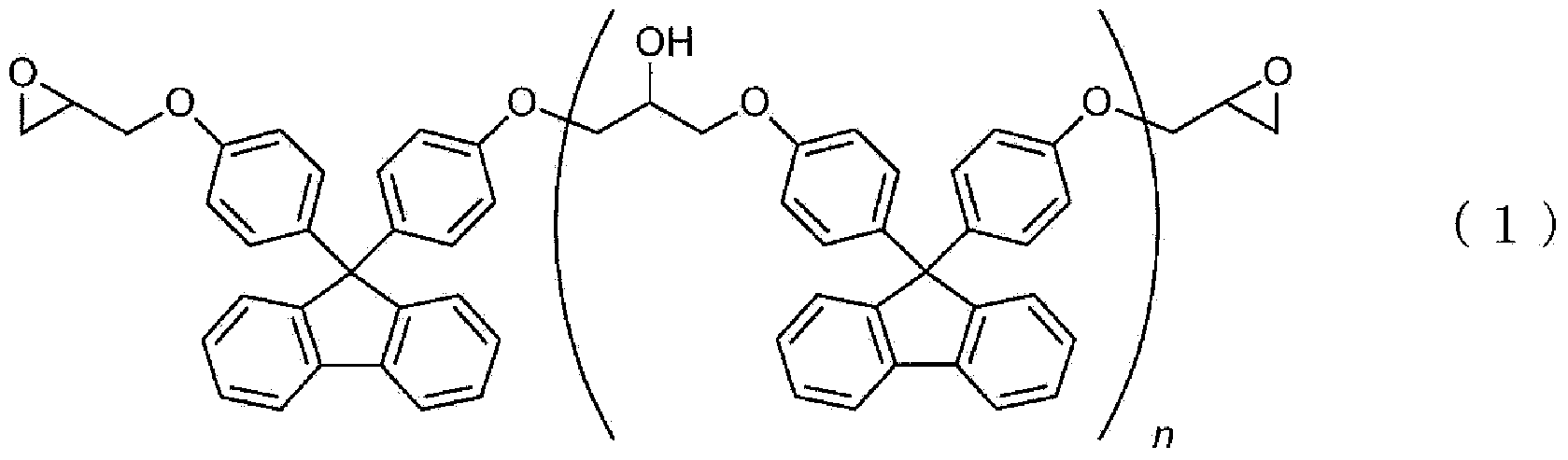

[0048] A-1: An epoxy compound represented by general formula (1) and having an average value of n of 0.2

[0049] A-2: Epoxy compound represen...

Embodiment 2~15

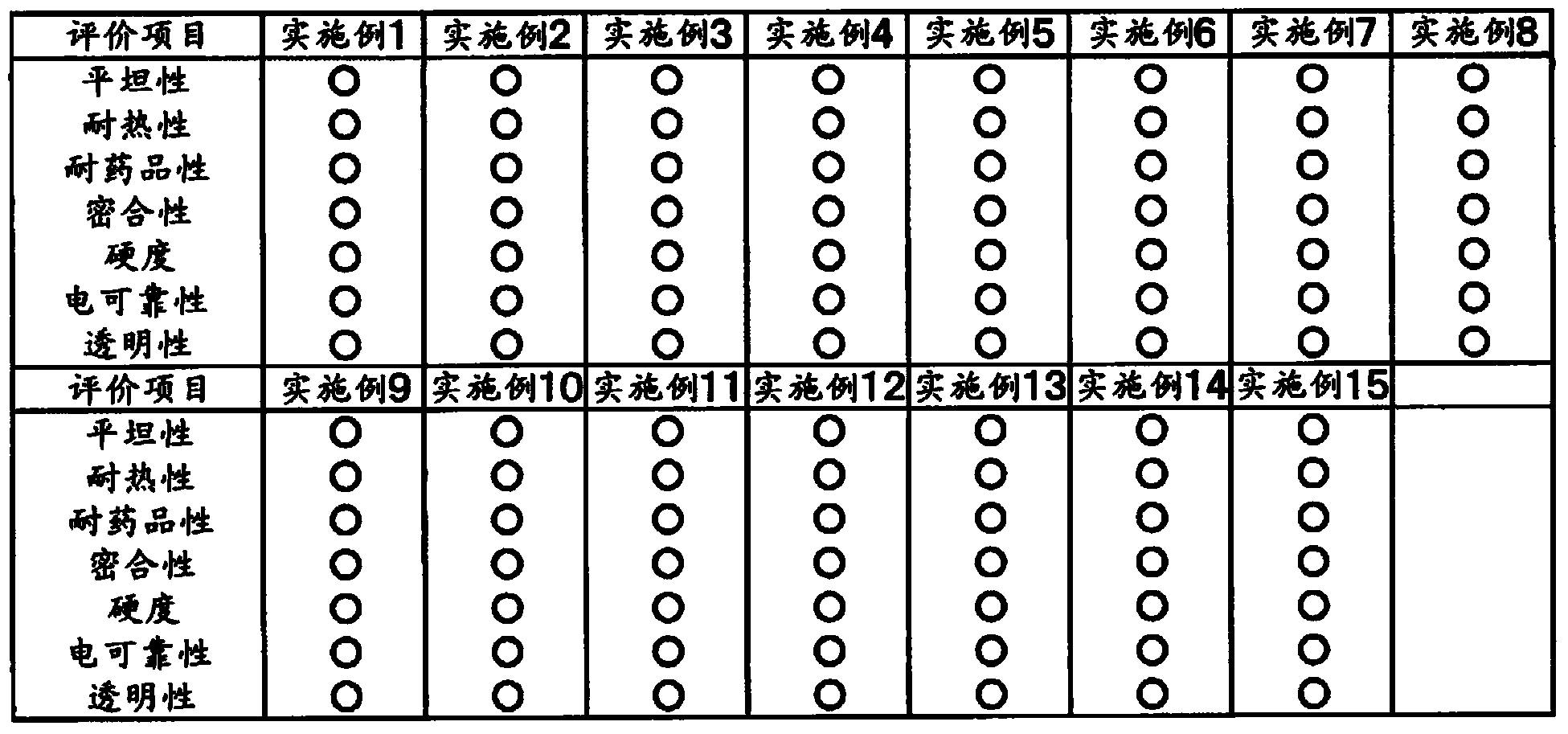

[0101] The composition of Example 1 was changed as shown in Table 1, and the preparation and evaluation of thermosetting compositions of Examples 2 to 15 were carried out in the same manner as in Example 1. The evaluation results are shown in Table 2. The curable compositions of Examples 2 to 15 simultaneously satisfied the flatness, heat resistance, adhesion, and hardness required for a protective film of a color filter, and were also excellent in chemical resistance, electrical reliability, and transparency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com