Composite heat-insulating plate

A thermal insulation composite board and protective board technology, applied in the direction of thermal insulation, building components, etc., can solve the problems of increasing energy consumption of refrigeration or heating equipment, poor thermal insulation performance of walls, poor thermal insulation performance, etc., and achieve beautiful and generous patterns , good flexibility, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

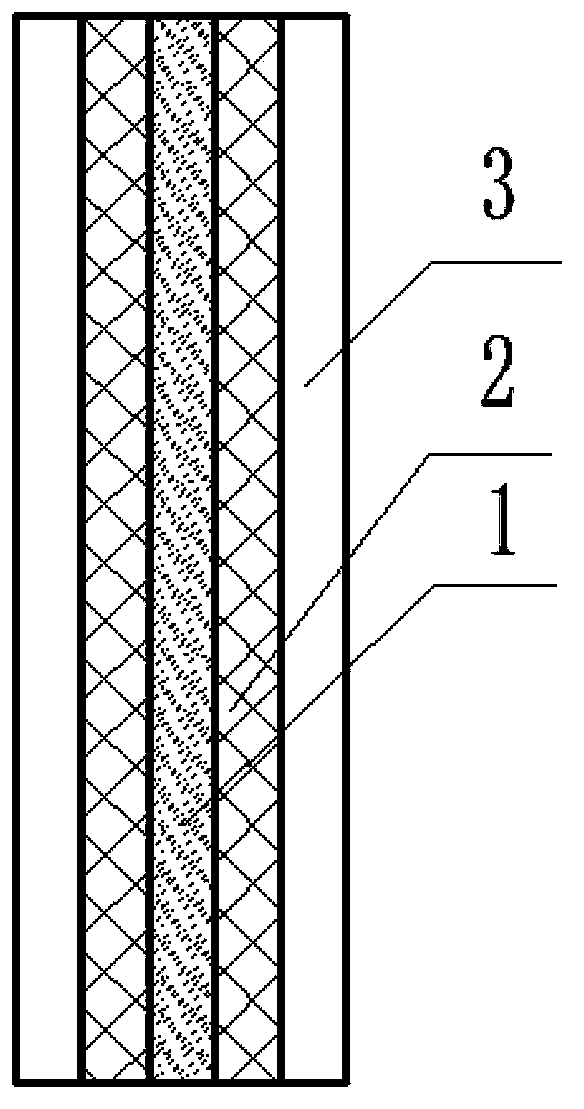

[0012] refer to figure 1 To illustrate the present invention, a thermal insulation composite board, the middle layer is a phase change energy storage material layer 1, the carbon fiber layer 2 is pressed on both sides, and the outermost side is provided with a metal protection plate 3, and the metal protection plate 3 may have holes and patterns , patterns, or all three.

[0013] The invention has the advantages of simple processing, light weight, good flexibility due to the use of the carbon fiber layer, and the metal protective plate on the outer layer not only has a good protective effect, but also has beautiful and generous patterns engraved on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com