Slide valve type variable-damping shock absorber matched with air spring and working method thereof

A technology of air springs and shock absorbers, applied in the direction of springs/shock absorbers, shock absorbers, springs, etc., can solve the problems that affect the performance of the suspension system, the damping coefficient cannot be changed, and the damping force cannot be adjusted, so as to reduce costs , Improving passability and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

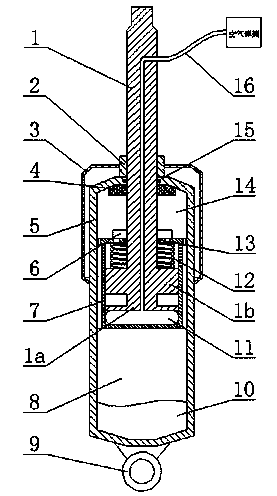

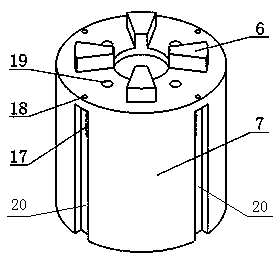

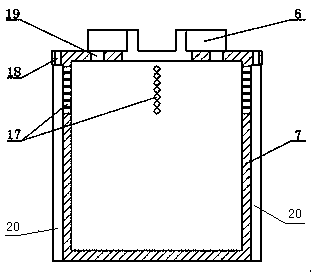

[0024] Referring to Fig. 1, the present invention contains a working cylinder 5 and a spool valve assembly, wherein the spool valve assembly includes a piston rod 1, a piston sleeve 7, a coil spring 12, an air bag spring 11, and a lower piston head 1a and an upper piston head 1b.

[0025] The piston rod 1 extends vertically downward from the center of the top of the working cylinder 5 in the inner cavity of the working cylinder 5. The inner cavity of the working cylinder 5 has a cylindrical piston sleeve 7, and the outer wall of the piston sleeve 7 and the inner wall of the working cylinder 5 There is a clearance fit between them, which can slide relative to each other. The lower end of the piston rod 1 is fixedly connected with the lower piston head 1a and the upper piston head 1b, and the piston rod 1, the upper piston head 1a, and the lower piston head 1b are regarded as a whole. The present invention has designed upper and lower piston heads, one is that the upper piston h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com