Device and method for dust collection and discharge of sintering flue gas

The technology of a sintering flue gas and ash discharge device, which is applied in the field of sintering flue gas treatment, can solve the problems of ash accumulation and clogging in the main pipe of circulating flue gas, and achieve remarkable ash discharge effect, which is beneficial to dust removal, and the ash discharge method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

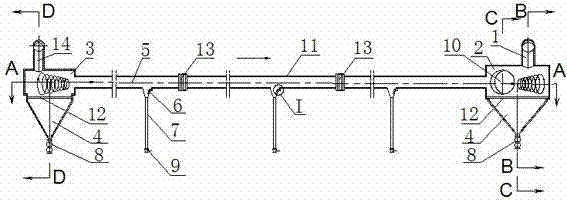

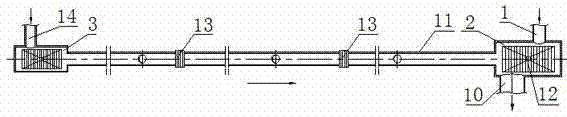

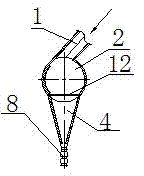

[0027] As shown in the figure, the sintering flue gas ash collection and ash discharge device is composed of the nose dust collection pipe 2 and the tail dust collection pipe 3 connected by the connecting pipe 5, which are used to connect the nose bellows and the nose dust collection pipe. The air intake pipe I1 between 2, the air intake pipe II14 used to connect between the tail air box and the tail dust collection pipe 3, the dust below the dust collection pipe 2 of the machine head and the dust collection pipe 3 of the tail respectively Collecting bucket 4, multiple dust collecting buckets 6 arranged on the connecting pipe 5, flue gas outlet pipe 10 arranged on the dust collecting pipe 2 of the machine head, and the grating plate walking set in the dust collecting bucket 4 The platform 12, the double-layer ash unloading valve 8 located under the dust collection bucket 4, the ash discharge pipe 7 connected to the bottom of the dust collection bucket 6, and the single-layer he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com