60 degree chamfering aperture diameter rapid detection device

A detection device and orifice technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of long production preparation time, low work efficiency, large errors, etc., achieve high work efficiency, save man-hours, and improve management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

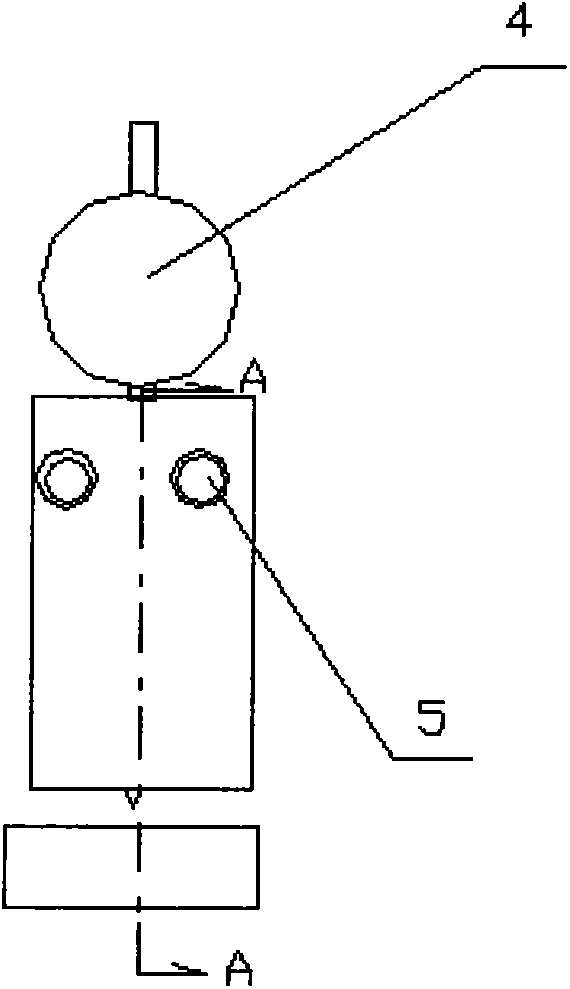

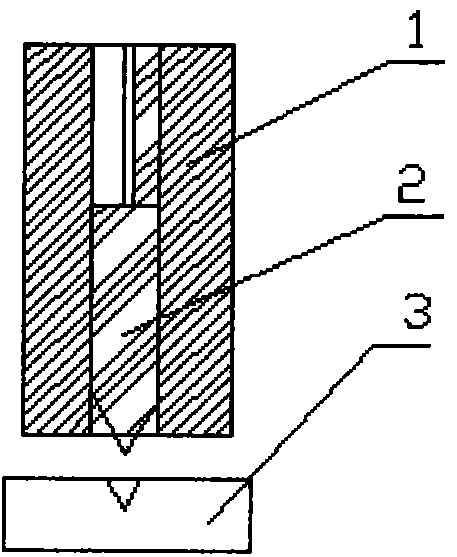

[0012] Such as figure 1 , 2 The shown 60° chamfer hole diameter rapid detection device is composed of a mandrel (2), a jacket (1) and a screw (5), and the mandrel (2) cooperates with the circular calibration gauge (3) workpiece cone , the overcoat (1) cooperates with the workpiece end face, the screw (5) limit mandrel (2) slides up and down in the overcoat (1), and the depth gauge (4) is connected with the measurement mandrel (2).

[0013] Use the depth gauge to measure the distance difference between the mandrel and the end surface of the jacket, and realize the rapid detection of the diameter of the 60° chamfer hole of the workpiece.

[0014] The mandrel slides along the inner hole of the jacket and is equipped with a depth gauge to meet the requirements for measuring the diameter of a 60° chamfered orifice in a certain range. In terms of measuring the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com