Tensile clamp of belt vulcanized joint and tensile tester of horizontal belt vulcanized joint

A tensile testing machine and fixture technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that the effectiveness of belt joints cannot be detected, and the tensile strength test of joints cannot be carried out. To ensure safe transportation and other issues, to achieve the effect of low production cost and test cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

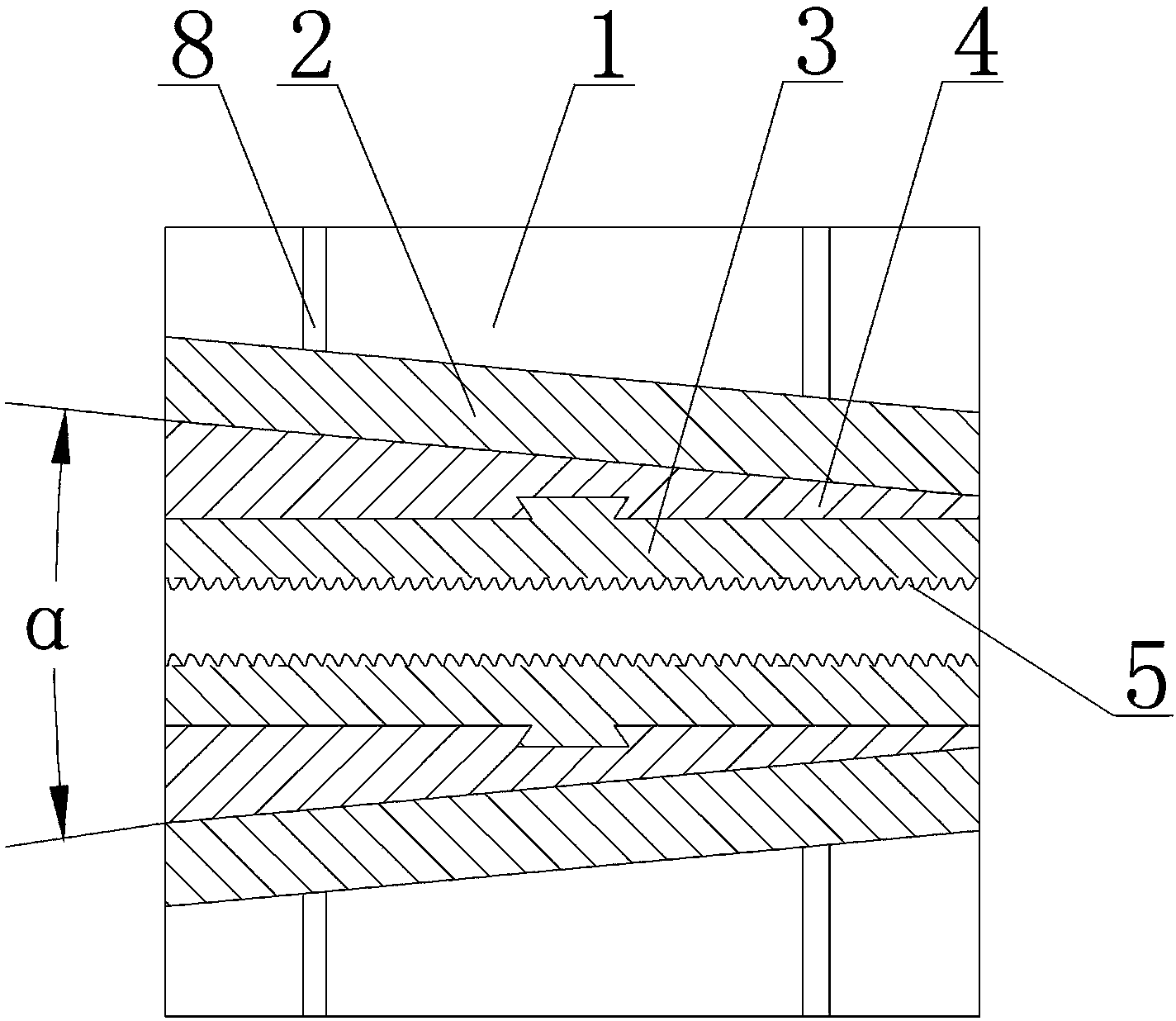

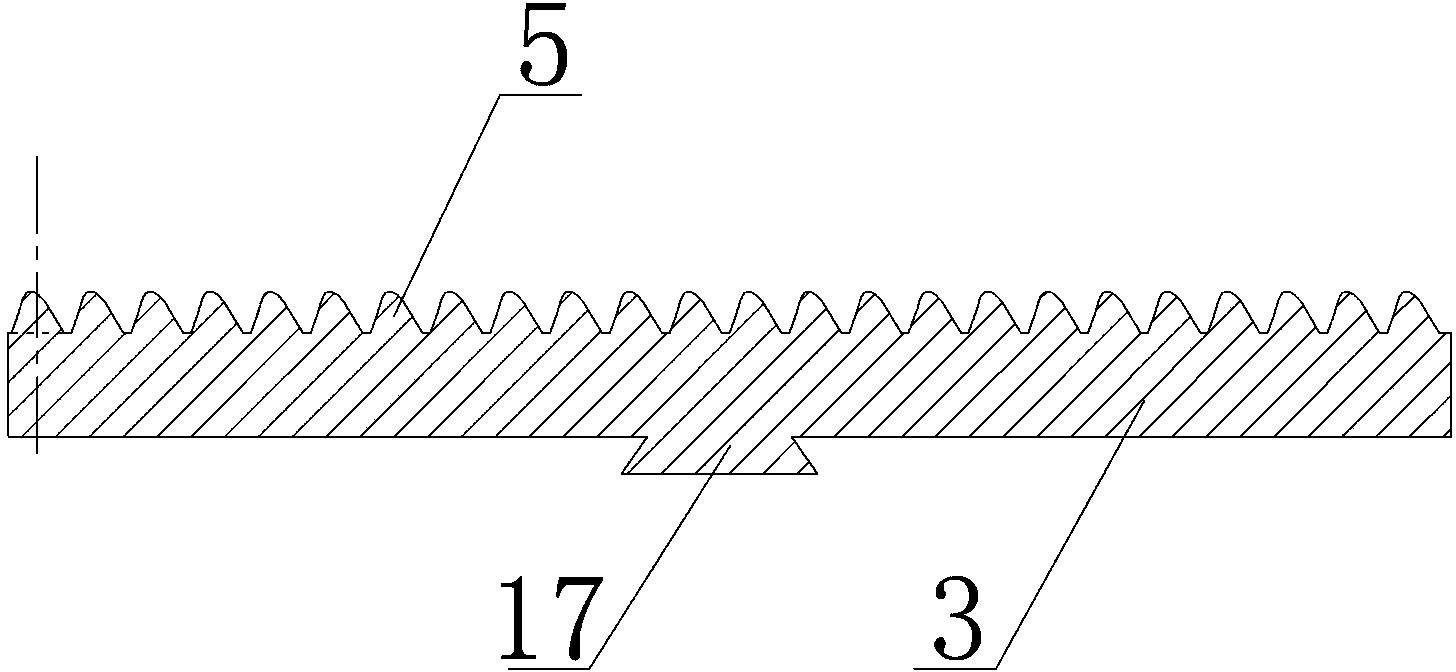

[0030] Embodiment one: see figure 1 — image 3 , Figure 6 , a tension fixture for belt vulcanized joints, including a bottom plate 1, two vertical plates 2 vertically fixed on the bottom plate 1, a wedge-shaped slide plate 4 and a clamping block 3, the angle between the inner surfaces of the two vertical plates 2 is α , and 9°≤α≤18°, the tops of the two vertical vertical plates 2 are fixed with connecting plates, the two sides of the vertical plates 2 are fixed with reinforcing plates 8, and two symmetrical wedge-shaped slide plates 4 are respectively matched and attached to the two vertical plates 2 on the inner surface, and the inner surfaces of the two wedge-shaped slides 4 are parallel to each other, and the inner surface of each wedge-shaped slide 4 and the clamping block 3 are connected together through the matching structure of the vertically arranged dovetail groove 16 and the dovetail strip 17, The inner surface of the clamping block 3 is uniformly provided with cl...

Embodiment 2

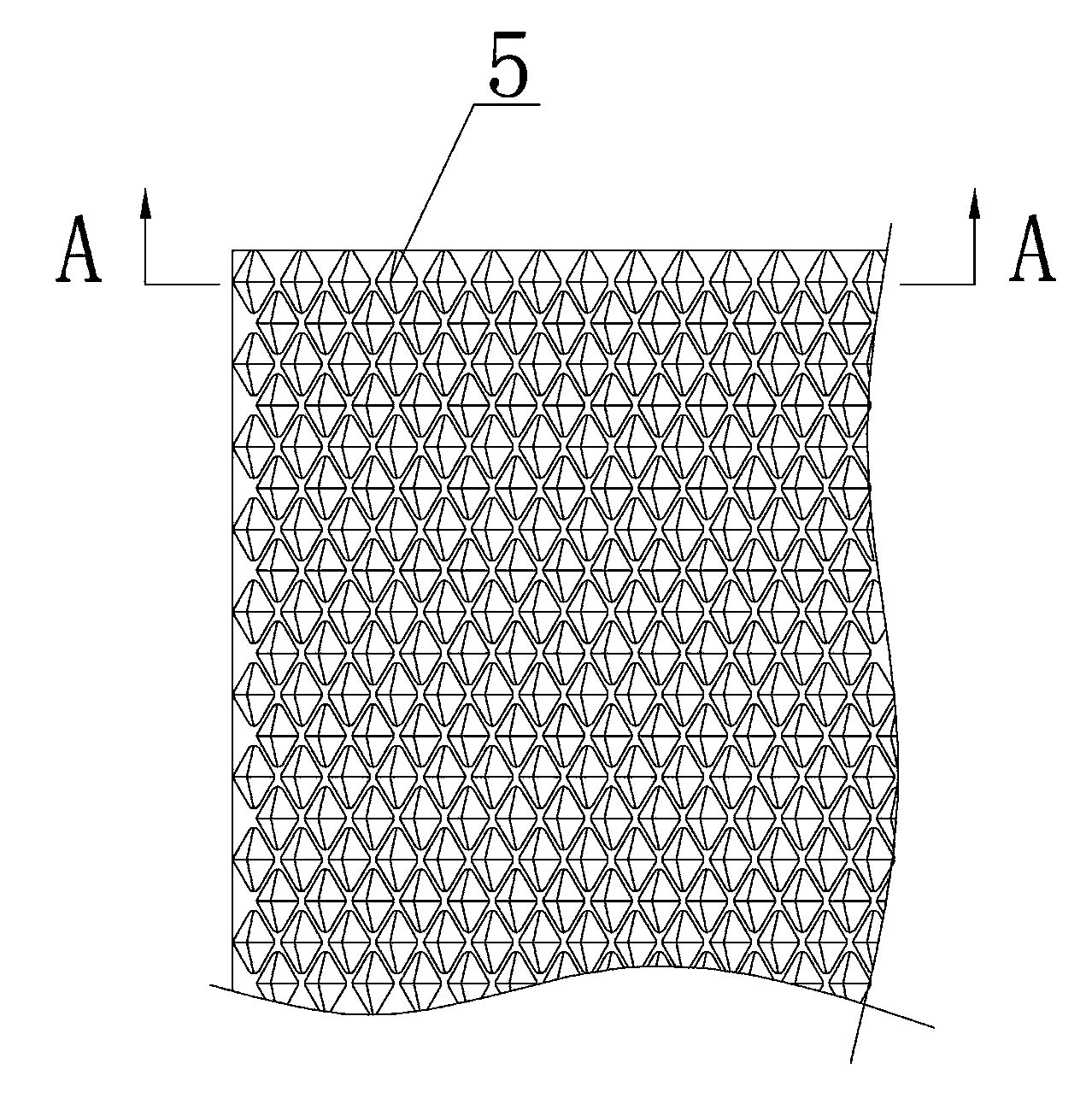

[0031] Embodiment two: see Figure 1-Figure 3 , Figure 6 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the bottom of the clamping protrusion 5 on the inner surface of the clamping block 3 is rhombus-shaped, and the rhombus-shaped The smaller apex angle is 55° or 60° or 65°, and the clamping convex teeth 5 are arranged in a rhombus grid.

Embodiment 3

[0032] Embodiment three: see Figure 1-Figure 7 , a horizontal belt vulcanized joint tensile testing machine, bolts are pre-embedded in the reinforced concrete ground, the strip base 9 is fixed on the pre-embedded bolts, and the fixed tensile fixture on the left side and the The movable stretching fixture on the right side is fixed with a bearing 11 on the right side base 9 of the movable stretching fixture,

[0033] The right side of the support 11 is fixedly equipped with a power unit through evenly distributed claws 10, and the power unit is a jack 20, or a hydraulic cylinder or an air cylinder. The output end on the right side of the power unit is connected to the pressure sensor 12, and the pressure The sensor 12 is fixedly connected to the load-bearing top plate 13 vertically arranged on its right end, and the two sides of the load-bearing top plate 13 are connected with the two sides of the movable stretching fixture through symmetrical pull rods 14, and the base 9 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com