Synchronous tracking image acquisition mechanism of automatic light inspector

An automatic light inspection machine and synchronous tracking technology, which is applied in the direction of optical testing defects/defects, etc., can solve the problems of unfavorable and accurate acquisition of image information, poor stability of image acquisition components, and large gaps in the arrangement of bottles to be inspected, so as to achieve enhanced scalability , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

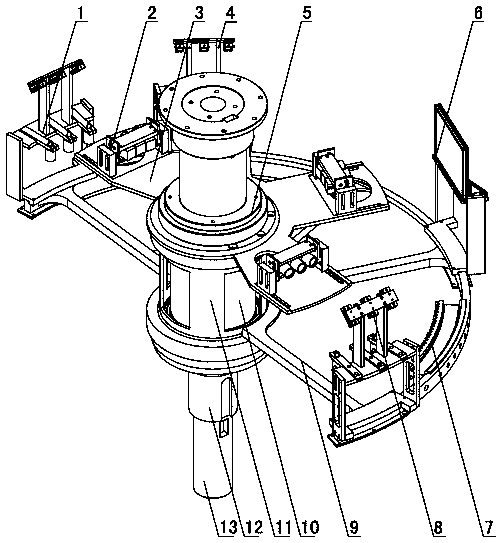

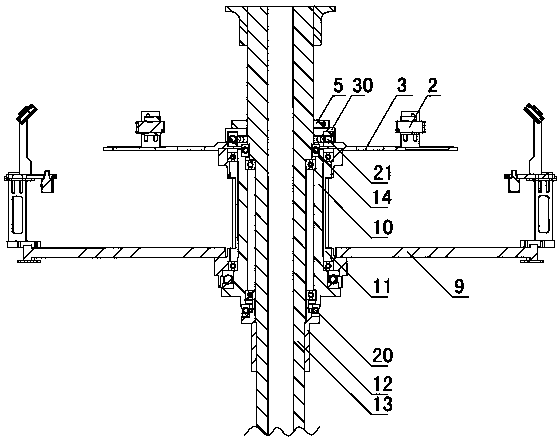

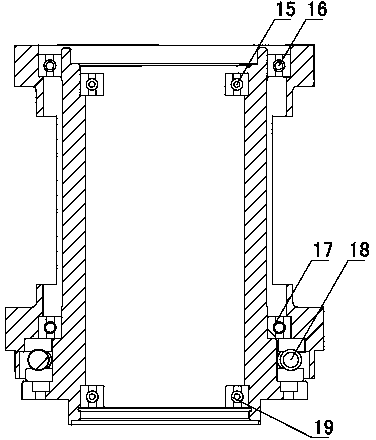

[0031] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~6 The present invention will be further described.

[0032] Figure 1~2 As shown, the synchronous tracking image acquisition mechanism includes a central shaft 13, a synchronous tracking assembly, an image acquisition assembly 2 and a light assembly installed on the synchronous tracking assembly.

[0033] The synchronous tracking assembly includes a rotary connector 11 , an upper turntable 3 and a lower turntable 9 , and the rotary link 11 and the fixed sleeve 10 are slidably connected by a bearing. The upper turntable 3 is fixed on the top of the rotary connector 11, and the upper turntable 3 is provided with a plurality of fixed platforms radially starting from the center, and a group of image acquisition components 2 are fixed at the end of each fixed platform. In this embodiment, there are four fixed platforms and image acquisition components 2, and the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com