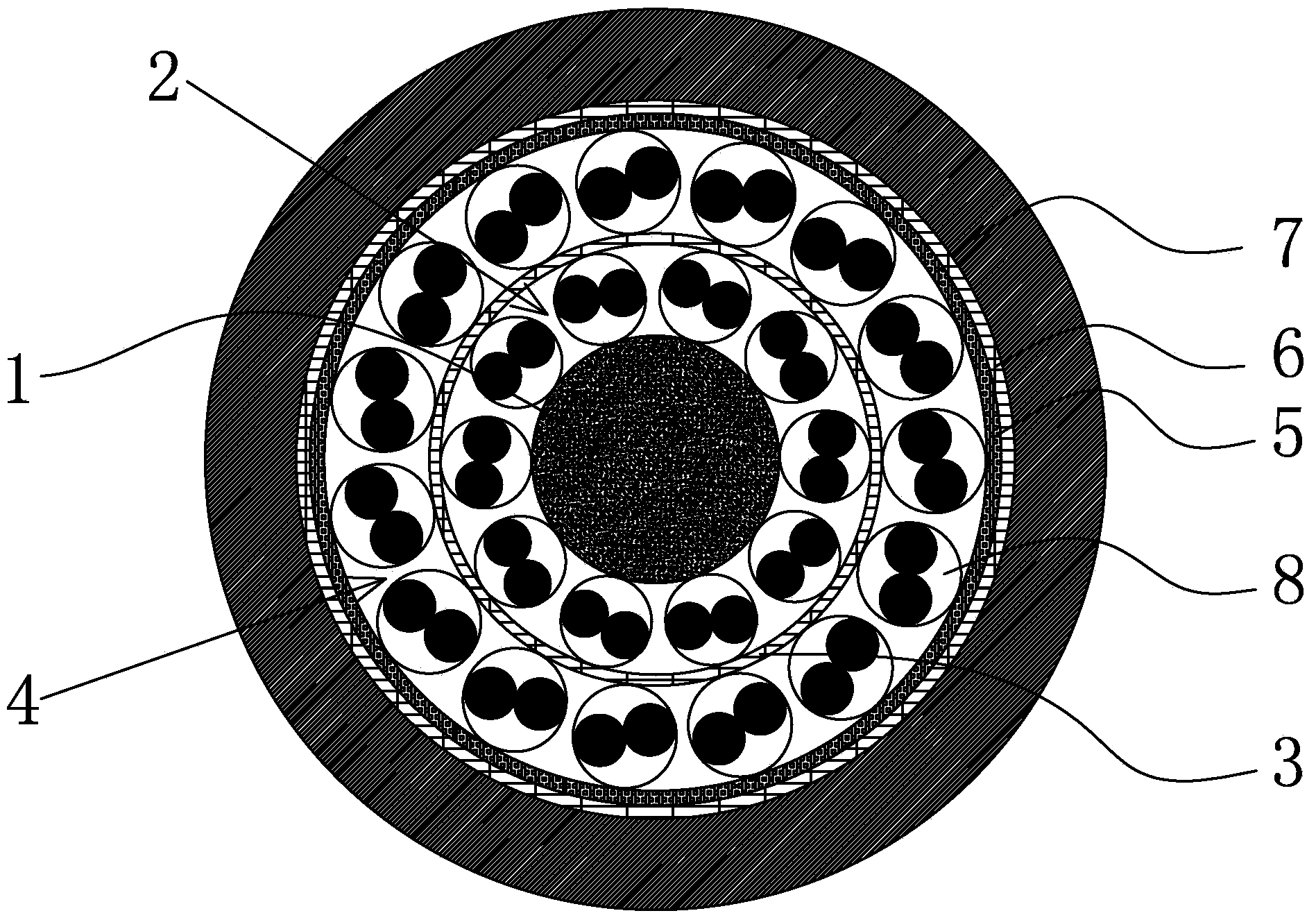

Large-pair-number shielding cable

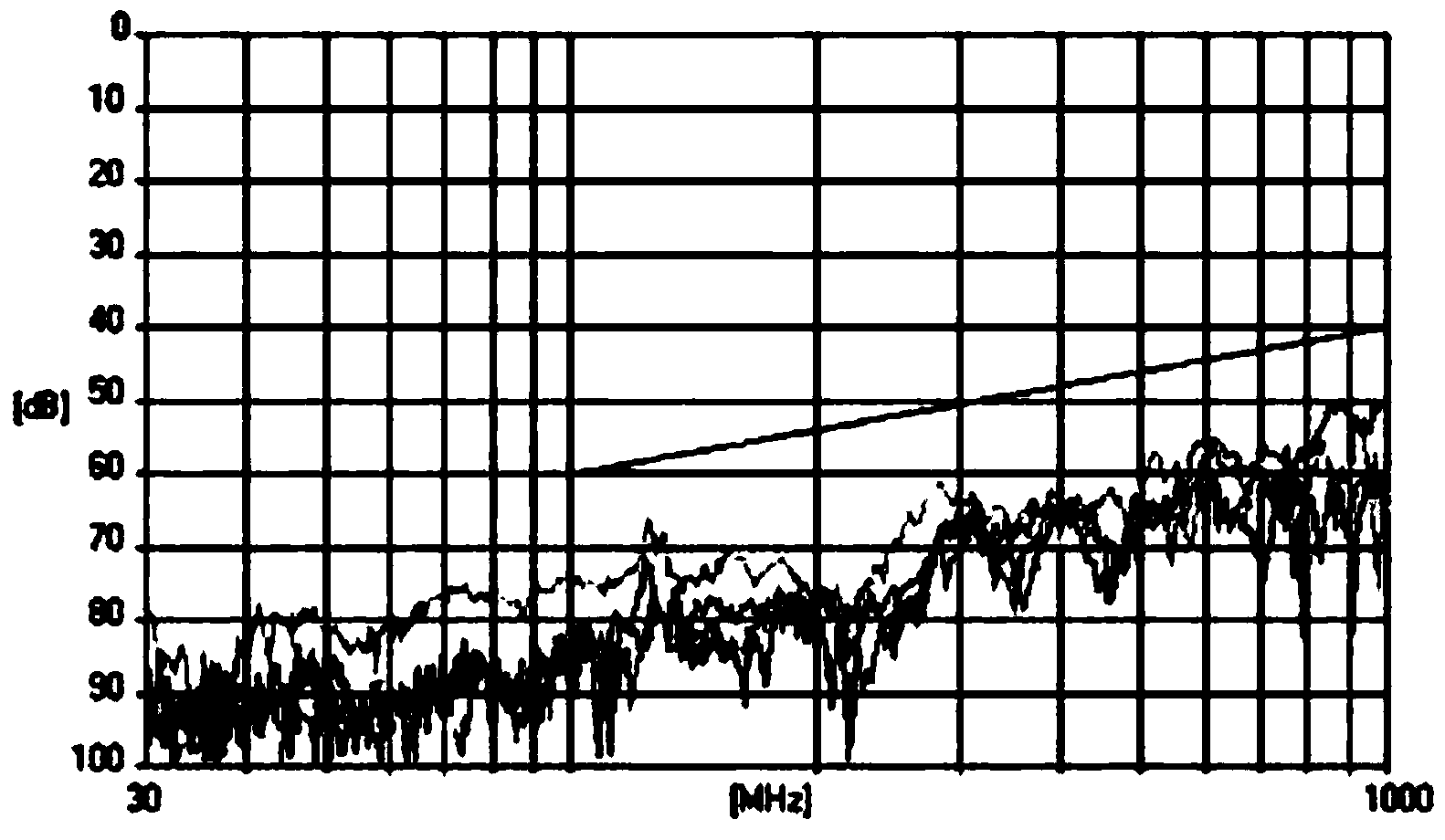

A cable and logarithmic technology, applied in the field of large logarithmic shielded cables, can solve the problems of poor electromagnetic shielding effect, poor effect, unstable data signal transmission, etc., achieve stable signal transmission, good effect, and improve electromagnetic interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

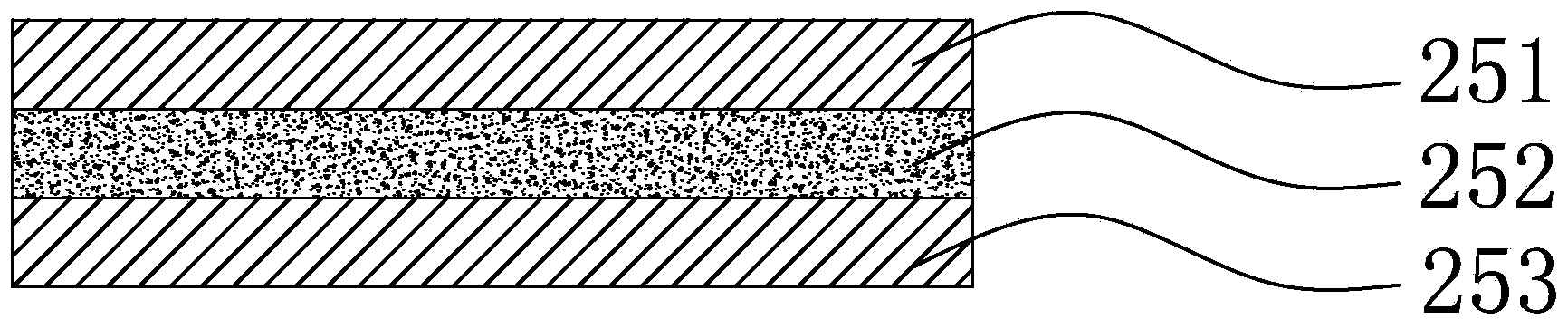

[0037] According to the composition and mass percentage of the aluminum foil of Example 1 in Table 1, the batching was carried out, and then the batching was heated to 750° C. for melting, and after standing for 5 minutes, deslagging and degassing refining were carried out. After refining, the alloy solution is poured into an alloy ingot at 710°C, then the temperature is lowered to 555°C for 3 hours, and then lowered to 470°C for 3 hours. Then the alloy ingot was hot-rolled, the rolling temperature was 460° C., and the final rolling temperature was 300° C. After the hot rolling, it was cold-rolled to prepare an aluminum foil with a thickness of 8 μm. After the aluminum foil is prepared, it is annealed to obtain a finished aluminum foil. The annealing temperature is 230° C., the heating time is 16 hours, and the holding time is 15 hours. Finally, the PVC film reinforcement layer with a thickness of 8 μm and the prepared aluminum foil were bonded by an adhesive to obtain a doubl...

Embodiment 2

[0040] According to the composition and mass percentage of the aluminum foil of Example 2 in Table 1, the batching was carried out, and then the batching was heated to 765° C. for melting, and after standing for 7 minutes, deslagging and degassing refining were carried out. After refining, the alloy solution is poured into an alloy ingot at 725°C, then the temperature is lowered to 565°C for 3 hours, and then lowered to 480°C for 2 hours. Then the alloy ingot was hot-rolled, the rolling temperature was 480° C., and the final rolling temperature was 320° C. After the hot rolling, it was cold-rolled to prepare an aluminum foil with a thickness of 10 μm. After the aluminum foil is prepared, it is annealed to obtain a finished aluminum foil. The annealing temperature is 245° C., the heating time is 18 hours, and the holding time is 12 hours. Finally, the PE film reinforcement layer with a thickness of 6 μm and the prepared aluminum foil were bonded by an adhesive to obtain a doubl...

Embodiment 3

[0043] According to the composition and mass percentage of the aluminum foil of Example 3 in Table 1, the batching was carried out, and then the batching was heated to 780° C. for melting, and after standing for 10 minutes, deslagging and degassing refining were carried out. After refining, the alloy solution is poured into an alloy ingot at 750°C, then the temperature is lowered to 580°C for 3 hours, and then lowered to 500°C for 1.5 hours. Then the alloy ingot was hot-rolled, the rolling start temperature was 490° C., and the final rolling temperature was 340° C. After the hot rolling, it was cold-rolled to prepare an aluminum foil with a thickness of 6 μm. After the aluminum foil is prepared, it is annealed to obtain a finished aluminum foil. The annealing temperature is 260° C., the heating time is 18 hours, and the holding time is 13 hours. Finally, the PET film reinforcement layer with a thickness of 10 μm and the prepared aluminum foil were bonded by an adhesive to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com