Pneumatic encrusting machine and implementation method thereof

A stuffing machine and stuffing technology, which is applied in the directions of baking, dough processing, food science, etc., can solve the problems of waste of manpower and material resources, high production and use costs, and difficulty in forming, so as to reduce production costs and use cost, diversification, and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

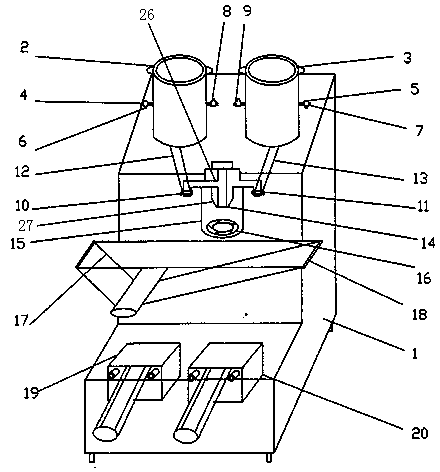

[0040] Such as figure 1 , 2 As shown, this embodiment provides a pneumatic stuffing machine, which mainly includes a material tank, a stuffing feeding mechanism, a noodle feeding mechanism, a forming mechanism, a conveying mechanism and a power mechanism. The invention installs an air bag in the material tank, uses the air bag as a material-holding device, and then uses air pressure to squeeze the air bag to shrink inward, so that the fabric or stuffing is extruded from the material tank through the discharge port.

[0041] The above mechanism is set with the chassis 1 as the carrier, and the specific setting method is as follows:

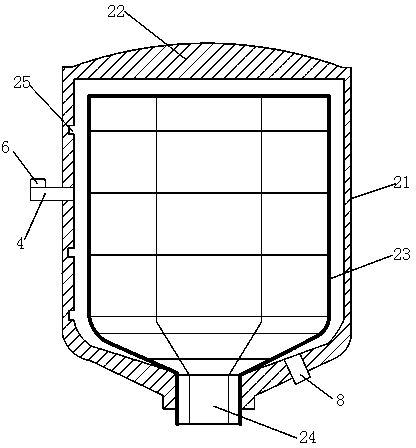

[0042] The material tank includes a tank body 21 with a discharge port 24 at the bottom and a tank cover 22 at the top, an air bag 23 installed in the tank body 1 and used for charging, and a mesh air groove 25 arranged on the inner wall of the tank body 1 , and communicate with the mesh air groove 25, and be provided on the tank body 21 for an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com