Mouth-shaped beam connecting device of composite wing and fuselage

A technology of composite materials and connecting devices, which is applied in the direction of fuselage, aircraft parts, transportation and packaging, etc., can solve the problems of increasing the tolerance of bolts and holes, large amount of machine addition, and waste of materials, so as to reduce the connection weight and facilitate Effects of processing and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

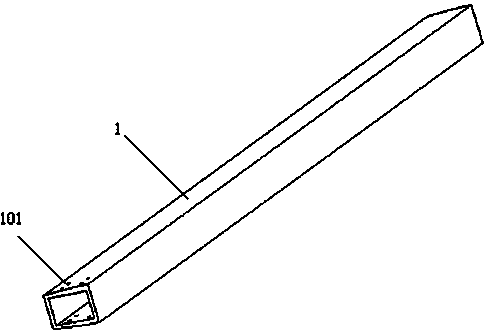

[0017] figure 1 The mouth-shaped beam 1 of the present invention is given, wherein the mouth-shaped beam 1 is formed by composite material layup, because there is a potential difference between the carbon fiber and the metal material, galvanic corrosion will occur, so the inner layer is a stripped fiber layup, The outside is a carbon fiber layup. There are several holes-101 on the upper and lower edge strips at one end of the mouth-shaped beam 1.

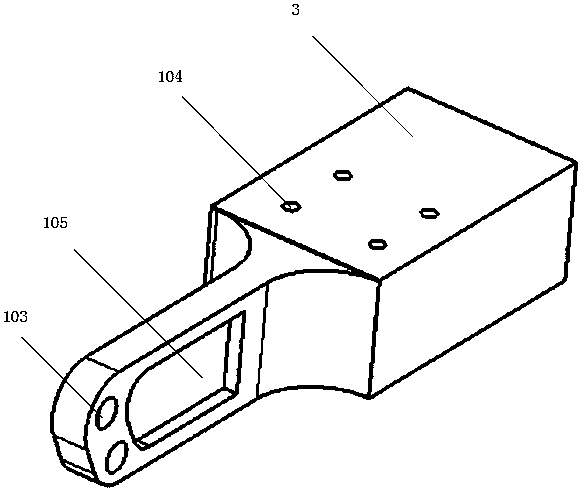

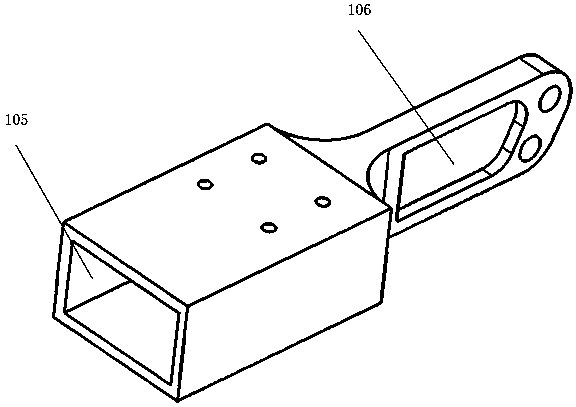

[0018] figure 2 and image 3 A schematic diagram of the mouth-shaped beam connector 3 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com