Residual-heat available roll-bar type rapid-cooling furnace

A roll bar and cold furnace technology, applied in the field of heat treatment equipment, can solve the problems of wasting heat energy, reducing production efficiency, occupying time, etc., and achieving the effect of reducing equipment volume, saving floor space, and reducing heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

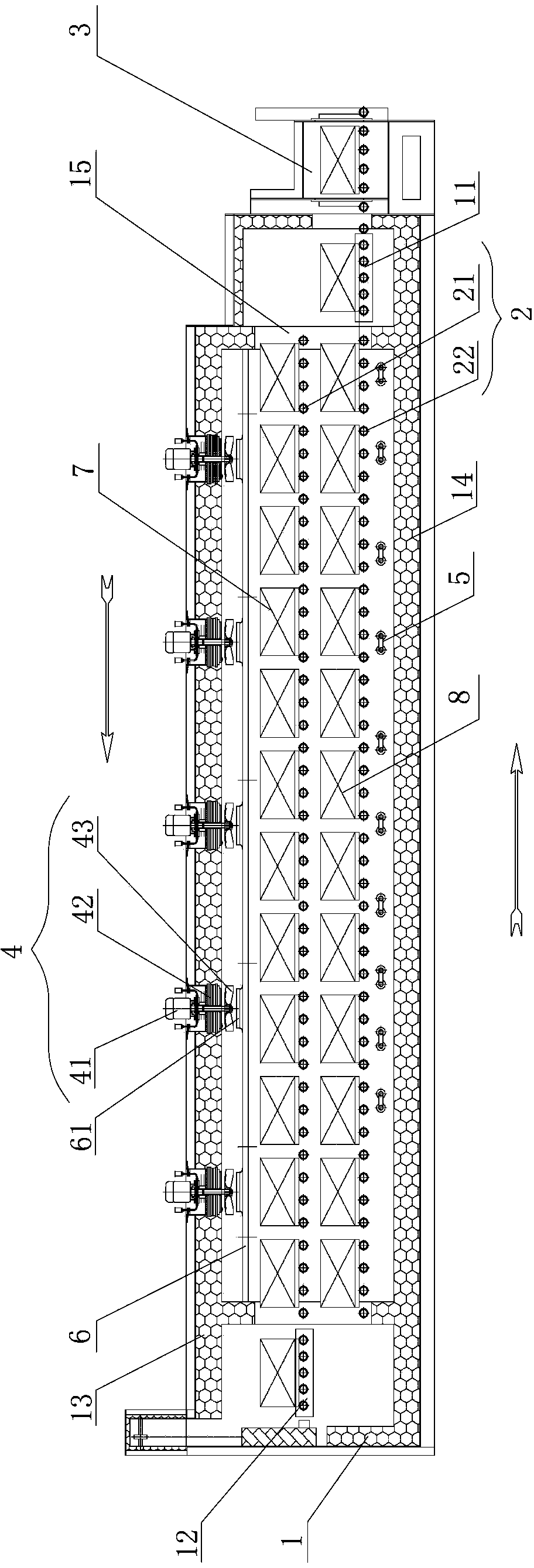

[0023] See figure 1 , the present invention has a rectangular body of furnace 1 and a conveying device 2 in the furnace; the conveying device 2 in the furnace is divided into upper and lower layers, including an upper layer cold workpiece input device 21 and a lower layer hot workpiece output device 22, and a cold workpiece input device 21 It is used to input the cold workpiece 7 into the next heat treatment furnace, and at the same time accept the energy released when the lower layer of the hot workpiece 8 is cooled for preheating; the hot workpiece output device 22 is used to further cool the hot workpiece 8 that has completed the heat treatment At the same time, the released energy is preheated to the upper cold workpiece 7, and the output is completed after cooling; the bottom of the cold workpiece input device 21 and the hot workpiece output device 22 are equipped with rollers, which can automatically input and output the workpiece under the control of the external operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com