Bridge supplementary pile preloading consolidation method

A bridge and preloading technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve problems such as increased burden, unfavorable bridge reinforcement effect, difficult to control the time period of deformation development, etc., to prevent slack and reserve small gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

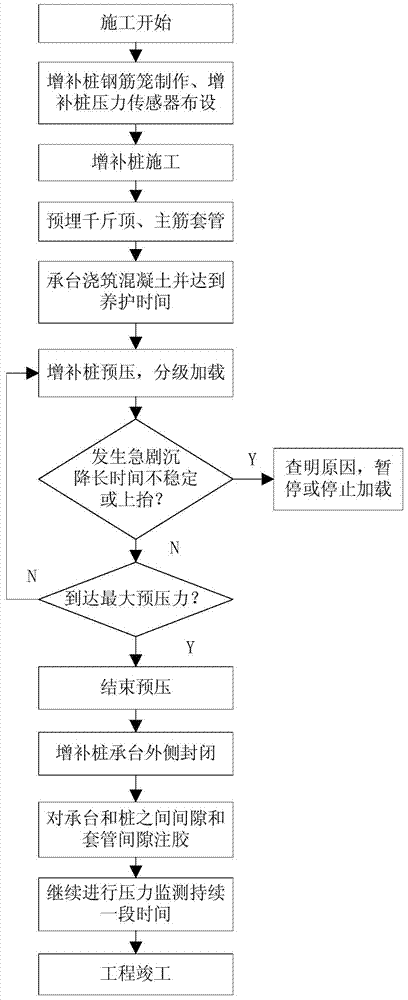

[0024] see figure 1 As shown, the embodiments of the present invention will be described in detail.

[0025] The invention relates to a method for preloading reinforcement of bridge supplementary piles. The method comprises the following steps:

[0026] Step 10. Make the reinforcement cage of the supplementary pile, and the main reinforcement is higher than the reinforcement cage of the supplementary pile by a certain height. 3-4 pressure sensors are arranged at 1-1.5m below the top of the reinforcement cage of the supplementary pile, and can be placed at the junction of each soil layer as required Laying a plurality of pressure sensors;

[0027] Step 20. Make holes around the original and old piles, then place the reinforcement cage of the supplementary pile, and finally pour concrete into the reinforcement cage of the supplementary pile. a height of the main rib;

[0028] Step 30: Use mortar to level the middle position of the top of the supplementary pile and paste a loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com