Foundation construction process of reforming self-roasting electrolytic bath into large pre-roasting electrolytic bath

A technology of foundation construction and electrolysis cell, applied in the field of foundation construction of aluminum electrolysis cell, can solve the problems of increasing project investment, unable to make full use of soil, prolonging project construction period, etc., to save project investment, avoid foundation settlement, and shorten project construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

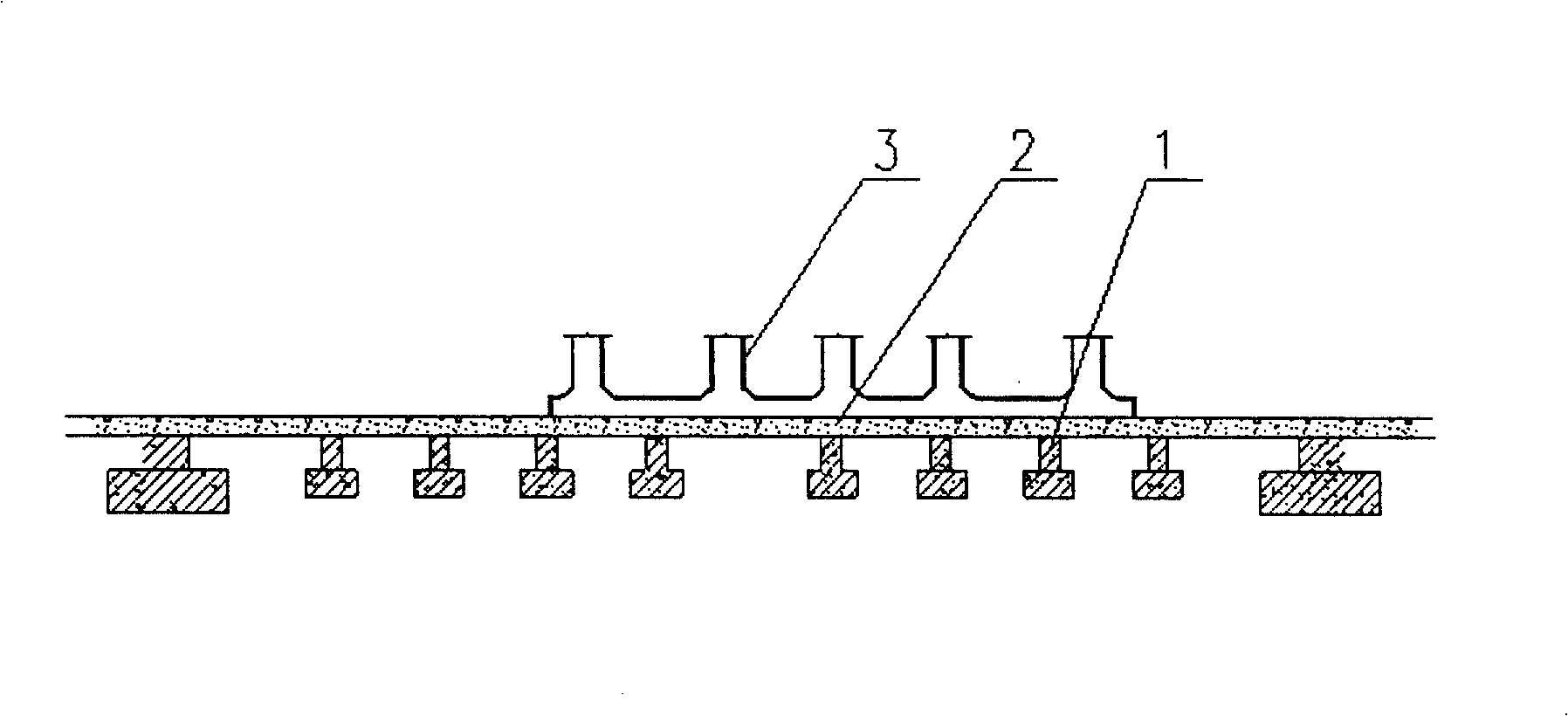

[0009] Embodiment of the present invention: the large-scale prebaked electrolytic cells are arranged in a single row along the factory building instead of the original double row, and the azimuth is rotated by 90 degrees. Such as figure 1 As shown, cut off the foundation small column and platform column (1) of the original self-baked electrolytic cell within the foundation range of the large pre-baked electrolytic cell to 300mm below the ground level, and use gravel or soil intercalated rocks as a cushion (2) to the ground Plane, the large prebaked electrolytic cell foundation (3) is made into a whole-slab foundation, the base is placed on the ground plane of the cushion layer (2), and the load on the bottom surface of the large prebaked electrolytic cell foundation is controlled to be ≤ 100Kpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com