Supporting and pressing type caulking machine for concrete face rockfill dam panels

A technology for concrete slabs and rockfill dams, which is applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as low compaction efficiency, poor quality, and difficult compaction, and achieve regular and beautiful molding, improve construction quality, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

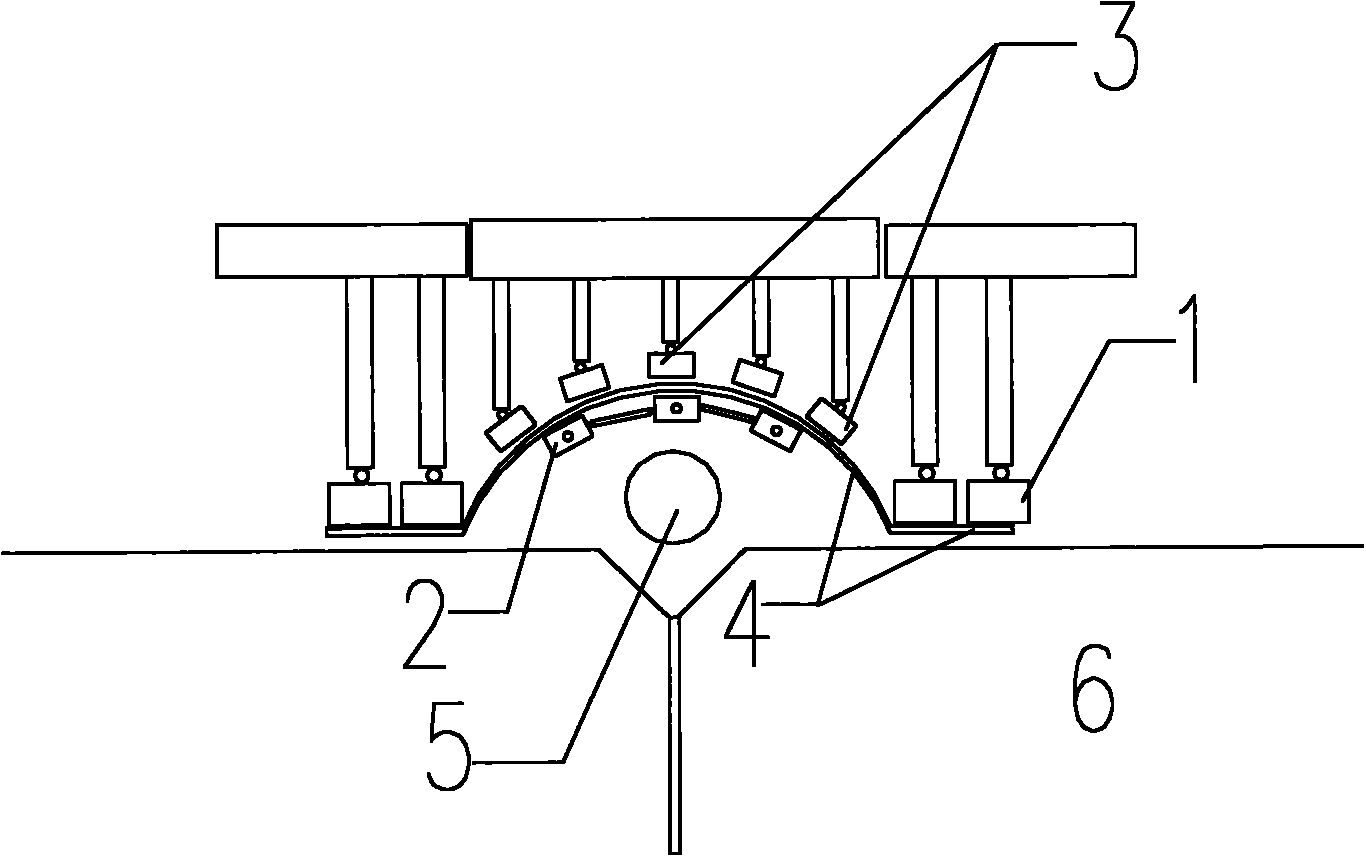

[0023] Holder such as figure 1 As shown, the small wheel 1 on the pressing device presses the two sides of the cover plate 4, and the small wheel 2 on the supporting device props up the middle part of the cover plate 4, so that the gap between the cover plate 4 and the concrete surface 6 is The surface forms a cavity; the flexible filler for caulking is mechanically pressed into the cavity through the injector 5, and the cover plate 4 bulges into the required convex arc surface under the filling pressure of the internal flexible filler, so that The caulking material in the cavity is tightly packed. The cover plate 4 is usually a rubber plate or a plastic plate. If the cover plate needs to be reused, the release agent can be applied to the lower surface of the cover plate. surface construction.

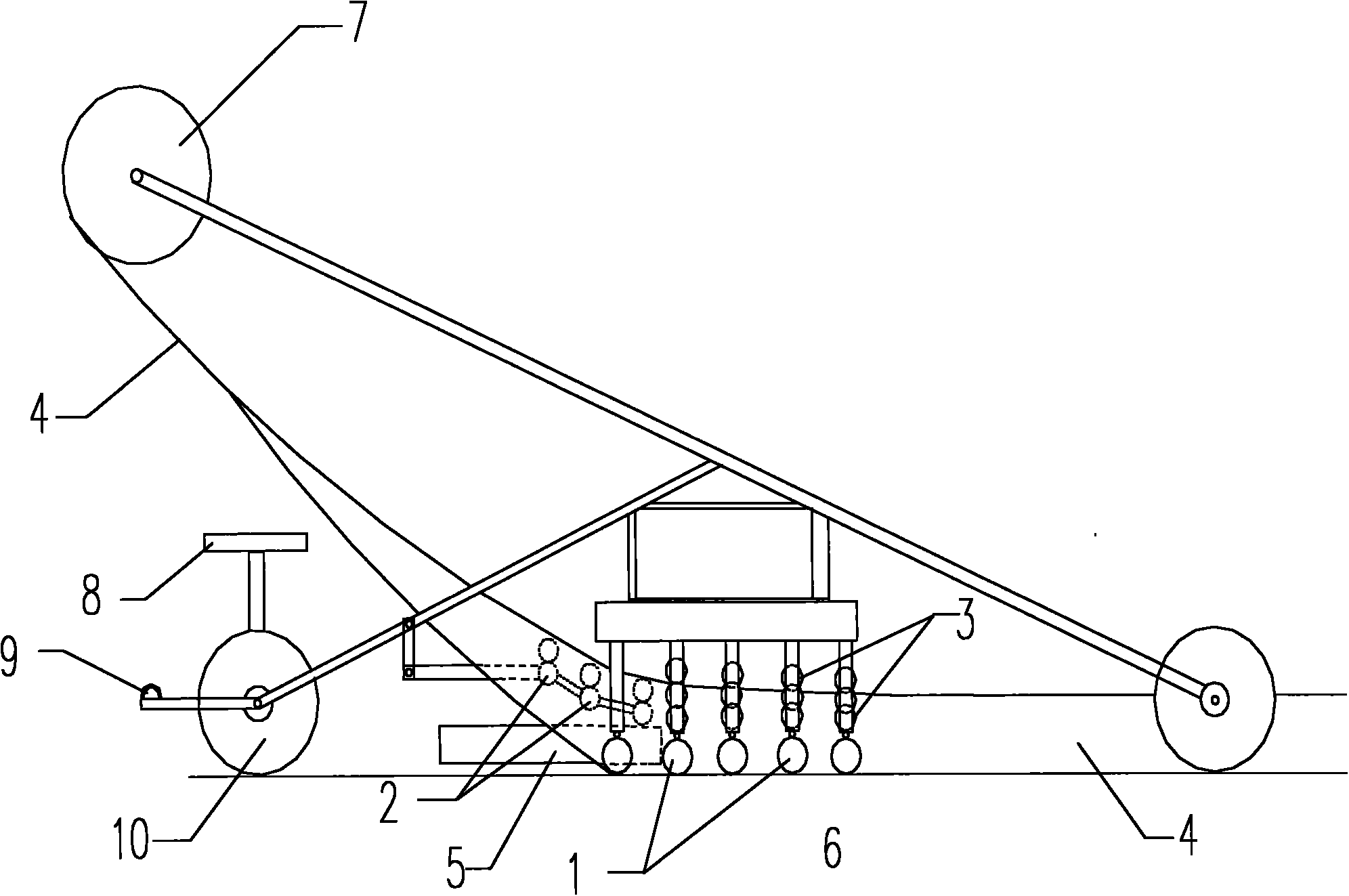

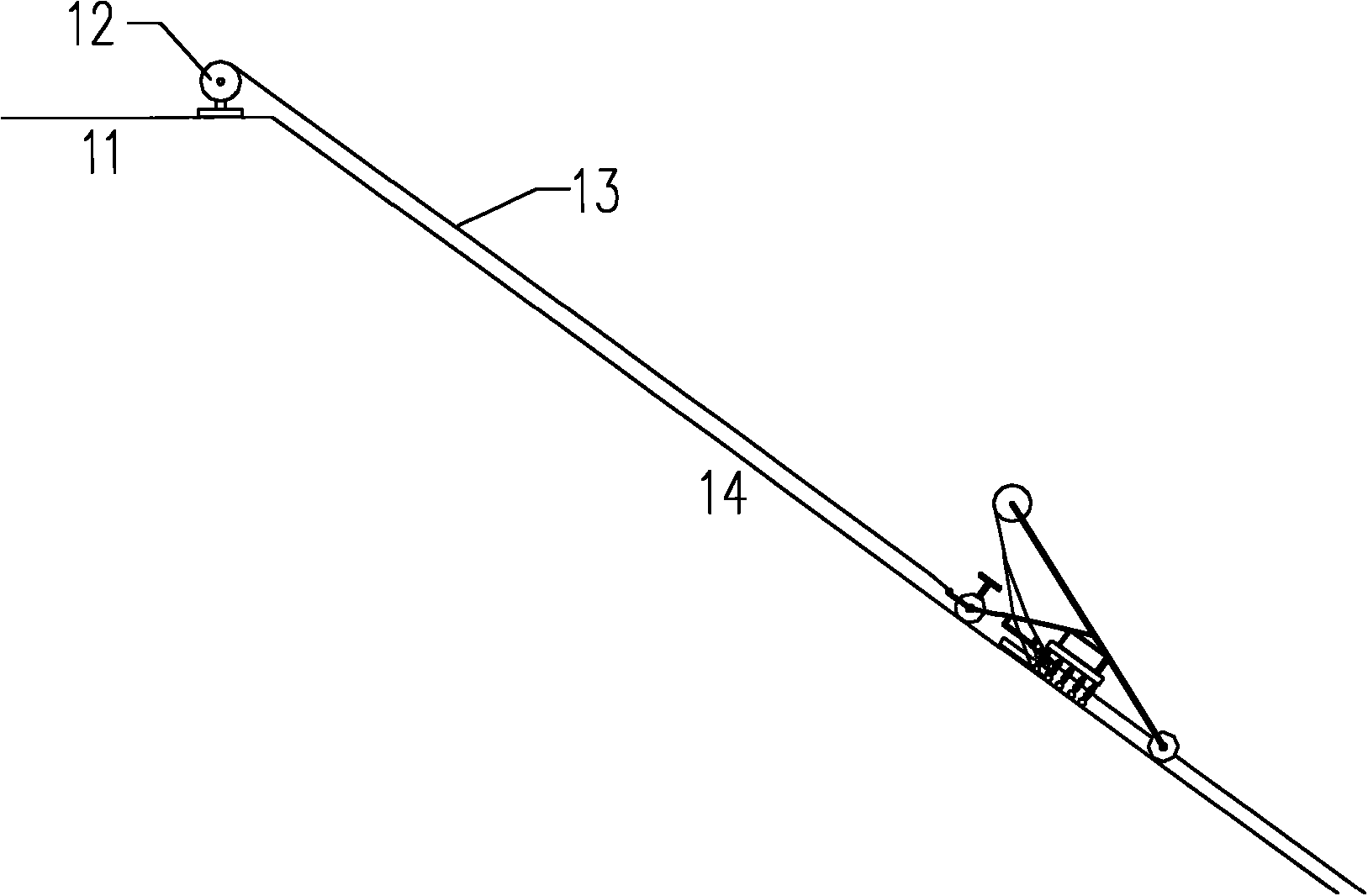

[0024] The structure of the support press caulking machine is as follows: figure 2 As shown, the caulking machine has a traveling wheel 10, which is pulled and advanced on the dam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com