Freezing device with coaxial liquid supply pipe and liquid return pipe

A liquid return pipe and liquid supply pipe technology is applied in the field of artificial freezing, which can solve the problems of damage to pressure resistance, increase in the diameter of the freezing pipe, and increase in the amount of steel used to improve thermal insulation performance, improve refrigeration efficiency, and reduce brine pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

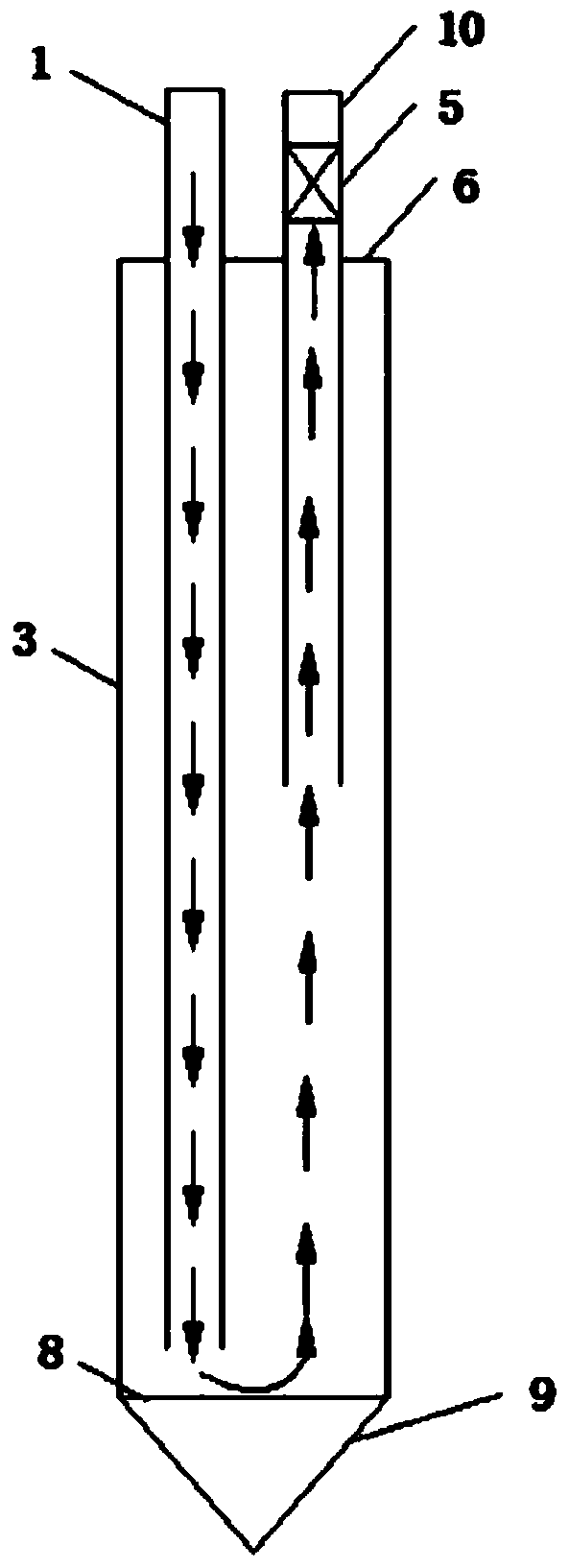

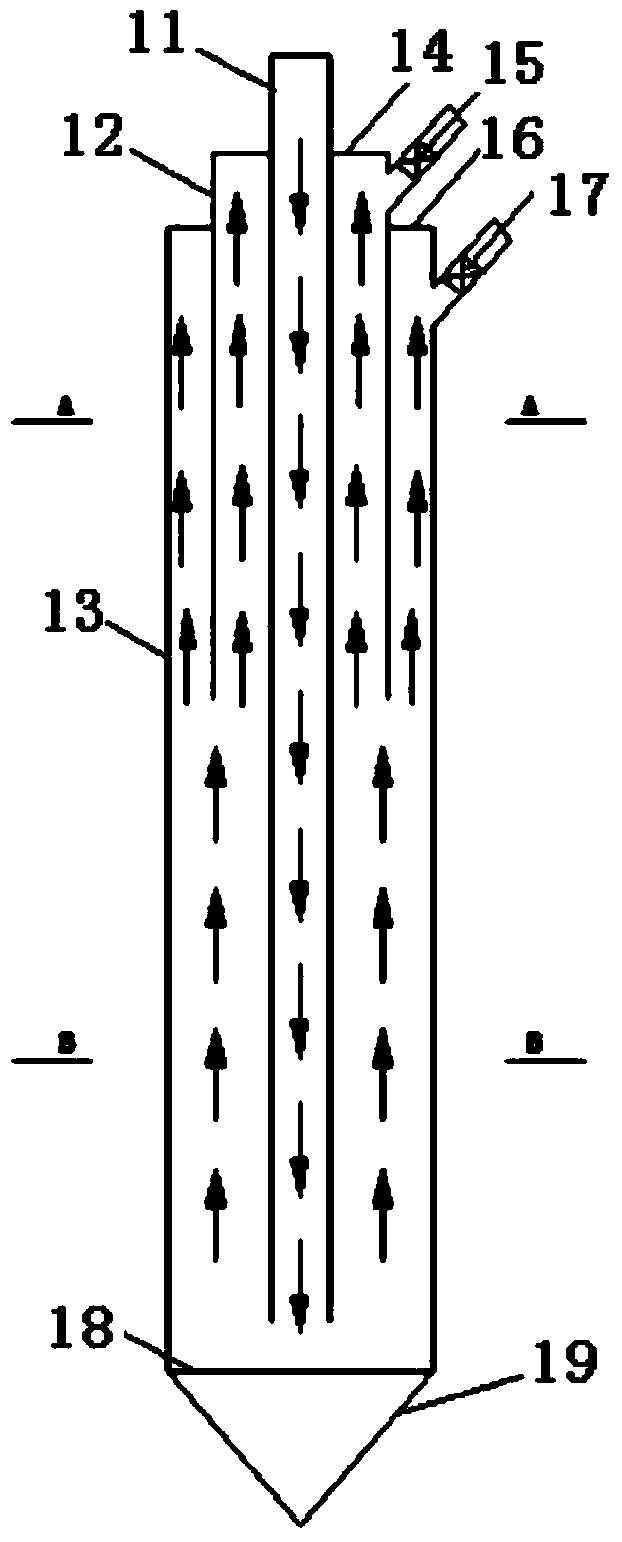

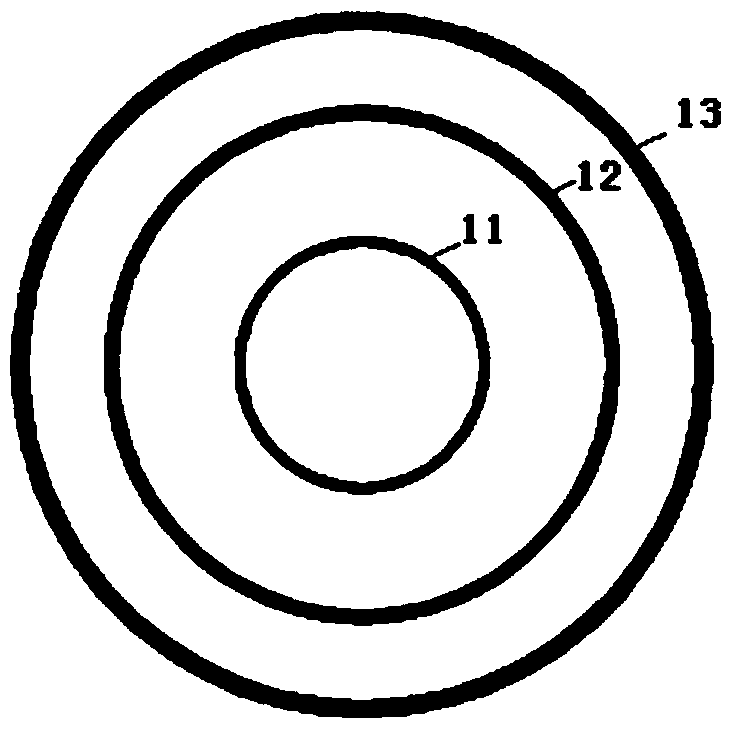

[0030] The single-inlet and double-return liquid pipe freezer of the present invention includes a liquid supply pipe, a liquid return pipe and a freezing pipe.

[0031] Wherein, the liquid supply pipe and the liquid return pipe are both made of polyethylene plastic or polyvinyl chloride.

[0032] The freezing tube is in the shape of a hollow cylinder, and its bottom end is closed by a lower sealing plate, and the lower end of the lower sealing plate is also provided with a bottom cone.

[0033] The liquid supply pipe and the liquid return pipe are inserted in the freezing pipe, and the distance between the bottom end of the liquid supply pipe and the bottom end of the freezing pipe must not only ensure the sufficient flow of the fluid, but also ensure the Cooling performance, the preferred distance is 1 / 4-1 / 2 of the diameter of the freezing tube.

[0034] The distance that the liquid return pipe is inserted into the freezing pipe is preferably 1 / 3-1 / 2 of the length of the fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com