Modularized integrated house

An integrated house and modular technology, applied in building components, buildings, building structures, etc., can solve the problem of not meeting the standard requirements of permanent houses, poor thermal insulation performance and comfort, and technical problems in interlayer connections, etc. problems, to achieve the effect of shortening the payback period of investment, civilized construction, and early benefits of housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

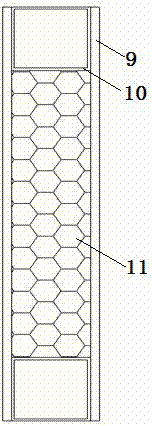

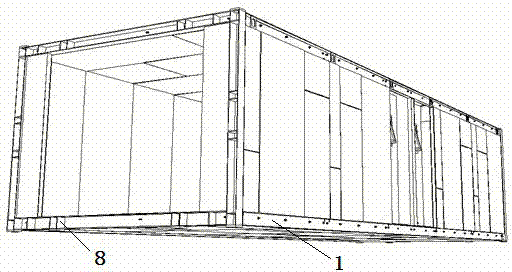

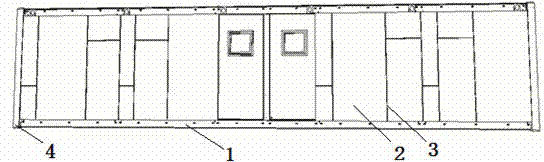

[0023] A modular integrated house in this embodiment includes a modular unit 1 with independent functions, the modular unit 1 is formed by screwing or welding a wall panel 2 and a steel structure frame 3 in a flow mode, and the wall panel 2 Utilizing the self-adhesive and flowing properties of polyurethane, the inorganic material panel and polyurethane are foamed by a high-pressure constant temperature method. The wall panel 2 includes a magnesium oxide board, a polyurethane layer and steel. The magnesium oxide board is bonded to the outside of the polyurethane layer, and the steel Wrapped at the end of the polyurethane layer. The thickness of the polyurethane layer of the 10cm-thick wall panel is 82mm, which can achieve 80% energy-saving standards and has a very high self-insulation effect; the steel structure frame 3 is welded and manufactured in the factory according to the modular design specifications.

[0024] The bottom of the module unit 1 is provided with a steel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com