Construction method and special component for increasing partial strength of precast concrete wall panel

A technology of prefabricated concrete and construction method, which is applied in the direction of building structure, building maintenance, construction, etc. It can solve the problems that are difficult to improve the mechanical characteristics of the wall, and achieve the effect of stable fixing, not easy to break, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

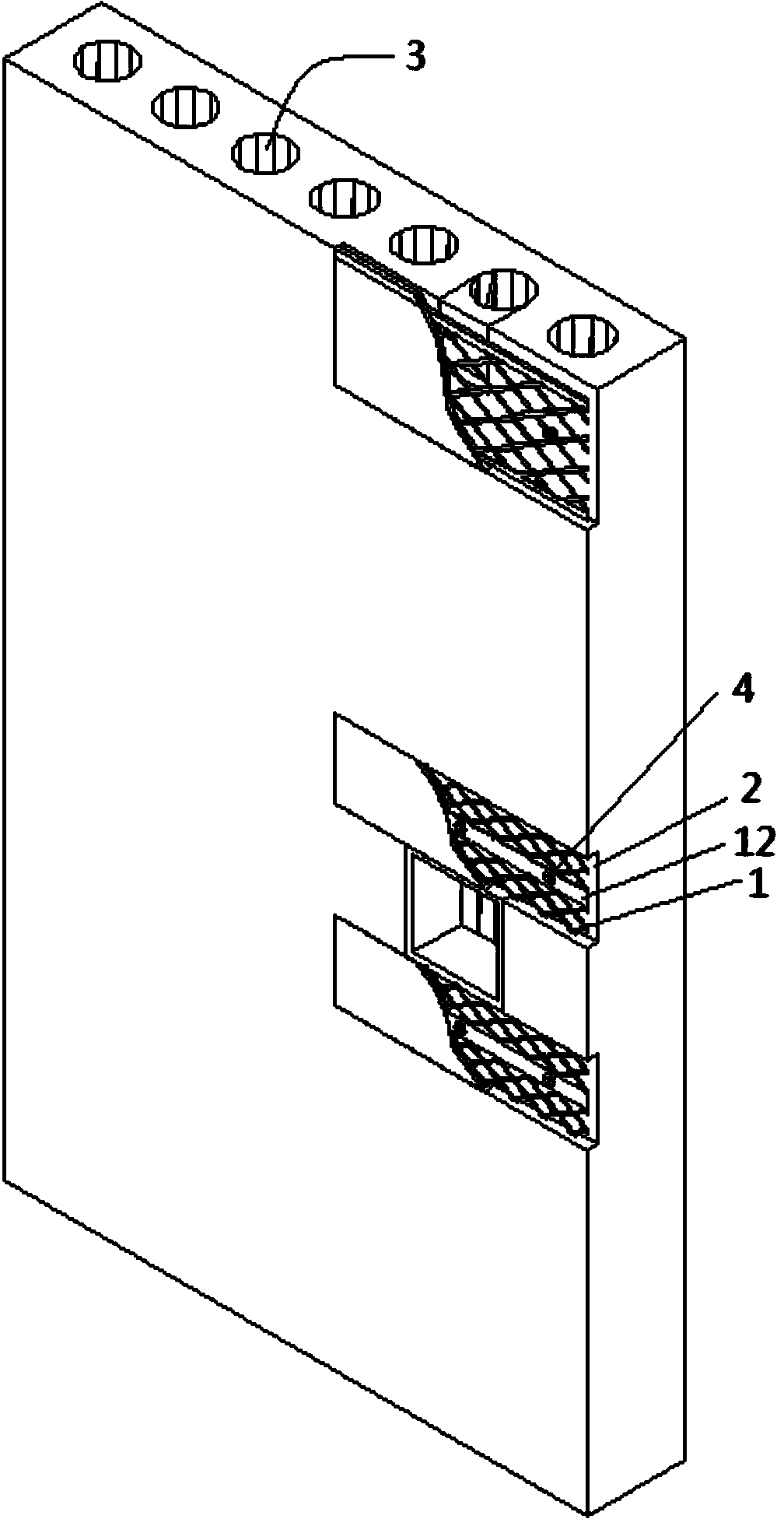

[0023] Example 1, see Figure 1 ~ Figure 4 The construction method for improving the local strength of the precast concrete slab wall provided by the present embodiment comprises the following steps:

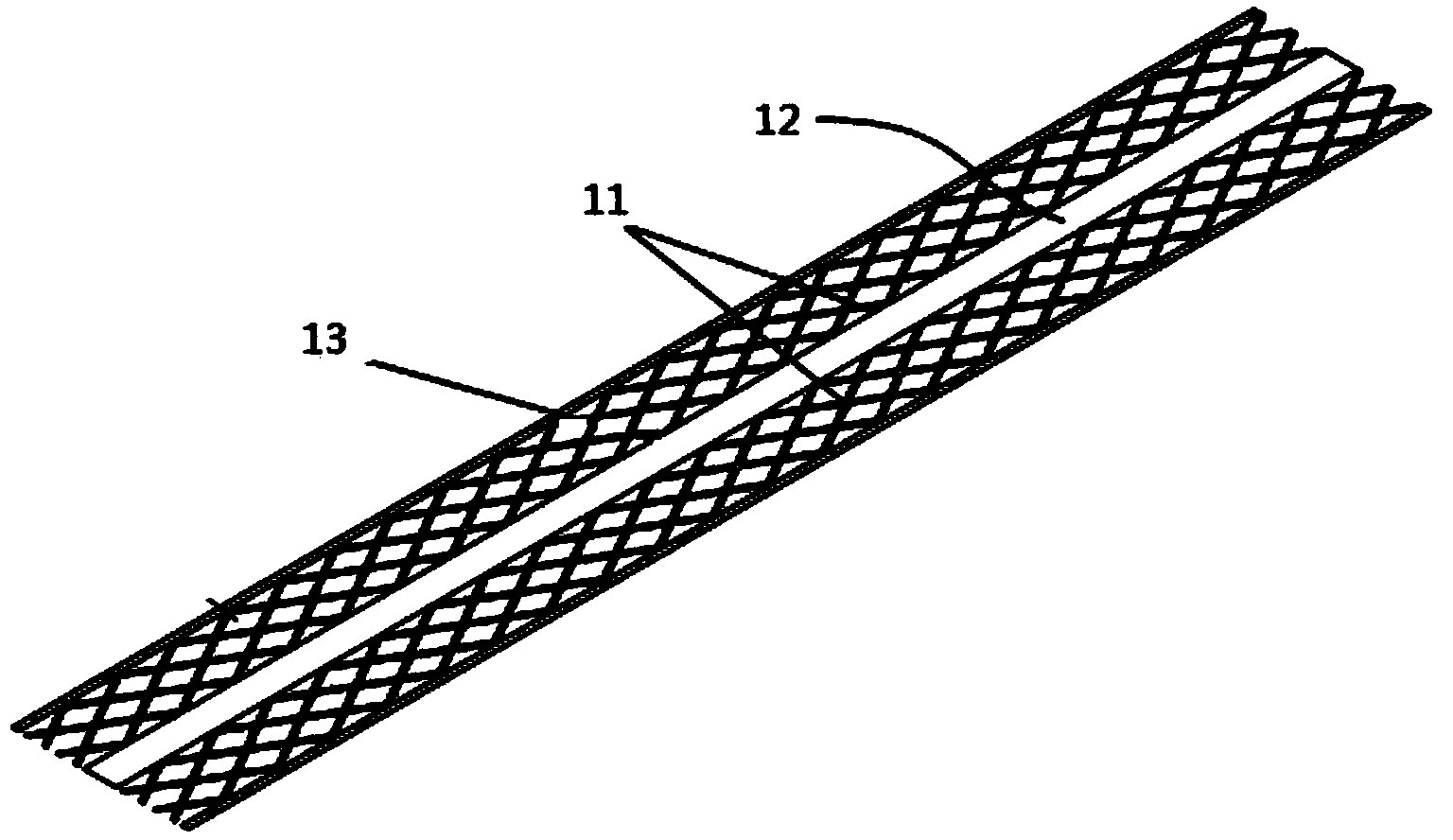

[0024] (1) prepare special-purpose mesh member 1, the thickness of this special-purpose mesh member 1 is h; Described special-purpose mesh member 1 is to be provided with the three-dimensional mesh structure of a plurality of three-dimensional meshes, comprises a plurality of intersecting each other to form the The side strips 11 of the mesh structure, and each side strip 11 is in a wave-like three-dimensional kink shape; the middle or side is provided with a rib 12 for the nail to pass through and nailed to the groove 2; the side is provided with an upper Folded or downturned hems 13.

[0025] (2) Grinding a groove 2 on the surface of the precast concrete slab wall or the surrounding wallboard, and the groove 2 is recessed into the surface of the concrete wallboard for 1.2 to ...

Embodiment 2

[0032] Example 2, see figure 1 , 2 The construction method for improving the local strength of the precast concrete slab wall provided by the present embodiment comprises the following steps:

[0033] (1) prepare special-purpose mesh member 1, the thickness of this special-purpose mesh member 1 is 1mm; Described special-purpose mesh member 1 is to be provided with the three-dimensional mesh structure of a plurality of three-dimensional meshes, comprises a plurality of intersecting each other to form the Side strips 11 of mesh structure, and each side strip 11 is in a wavy three-dimensional kink shape; the middle or side is provided with a rib 12 for the nail to pass through and nailed to the groove 2; the side is provided with an upper Folded or downturned hems 13.

[0034](2) Grind a groove 2 on the surface of the prefabricated concrete slab wall or the surrounding wallboard, and the groove 2 is recessed into the surface of the concrete wallboard by 5mm. The groove 2 is lo...

Embodiment 3

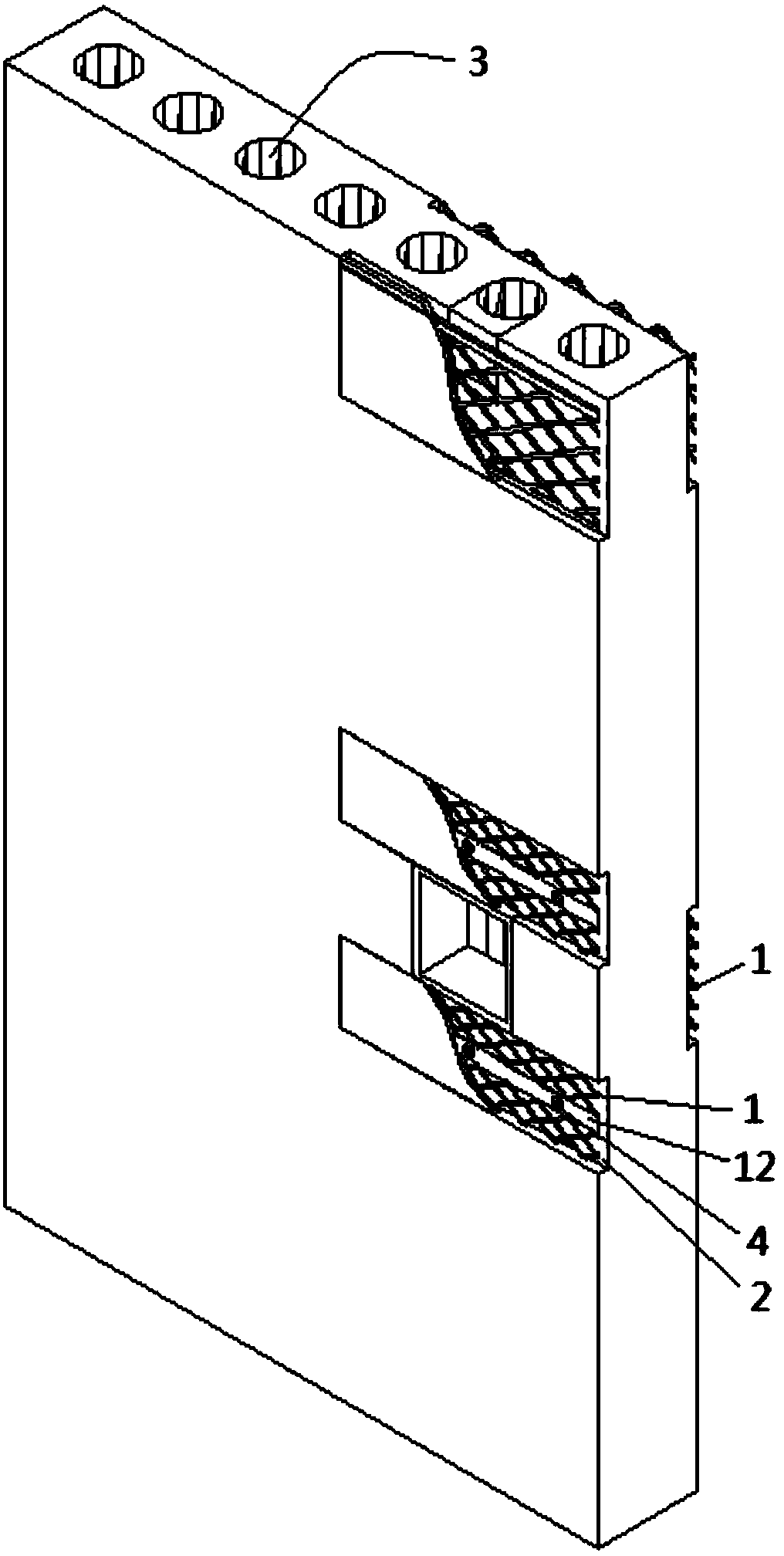

[0039] Example 3, see figure 1 , 3 , the construction method and special components for improving the local strength of precast concrete slab walls provided by this embodiment are basically the same as those of Embodiments 1 and 2, except that they include the following steps:

[0040] (1) prepare special-purpose net-like member 1, the thickness of this special-purpose net-like member 1 is 10mm; Described special-purpose net-like member 1 is the three-dimensional net-like structure that is provided with a plurality of three-dimensional meshes, comprises a plurality of intersecting each other to form this The side strips 11 of the mesh structure, and each side strip 11 is in a wave-like three-dimensional kink shape; the middle or side is provided with a rib 12 for the nail to pass through and nailed to the groove 2; the side is provided with an upper Folded or downturned hems 13.

[0041] (2) Grinding a groove 2 on the surface of the precast concrete slab wall or the surround...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com