An anchor cable drilling rig with Luoyang shovel head for roadway floor

A Luoyang shovel and bottom plate technology, applied in drilling tools, drilling equipment, earth-moving drilling, etc., can solve the problems of stuck drilling, bottom plate deformation, and can not be completely solved, and achieve flexible movement, high porosity, and hole forming. deep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

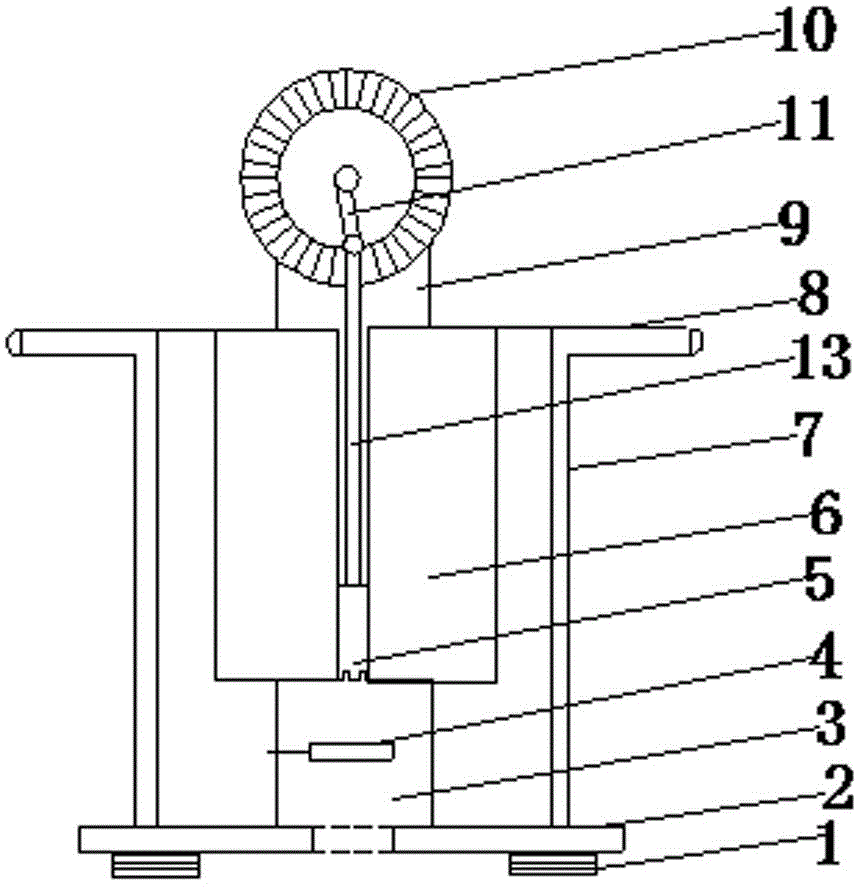

[0017] like figure 1 Shown, the present invention comprises walking crawler belt 1, chassis 2, base 3, stone swallowing bin 4, Luoyang shovel head 5, track portion baffle plate 6, outer baffle plate 7, handrail 8, machine neck 9, motor 10, crank 11, Equipment control switch 12 and connecting rod 13, the base 3 is installed on the chassis 2, the machine neck 9 is installed on the base 3, the motor 10 is installed on the machine neck 9, the track part baffle plate 6 is installed on the base 3, the track The front side of the baffle 6 is perpendicular to the output shaft of the motor 10, and the base 3 and the baffle 6 of the rail are connected as a whole. The outer baffle 7 is installed on the chassis 2 and is located on the outer side of the rail part baffle 6 , and the handrail 8 is welded on the outer baffle 7 .

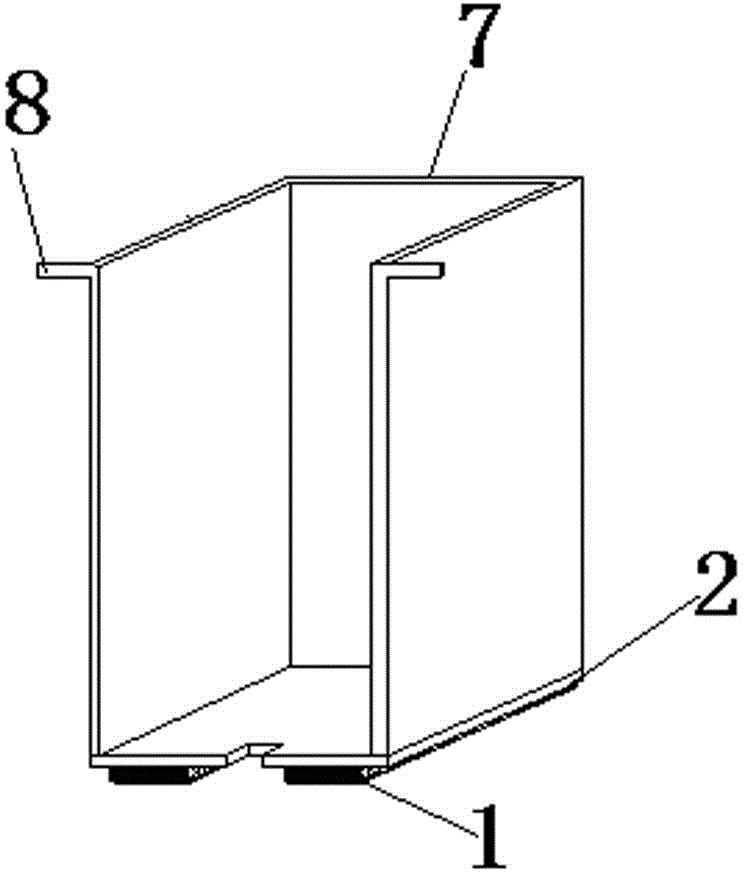

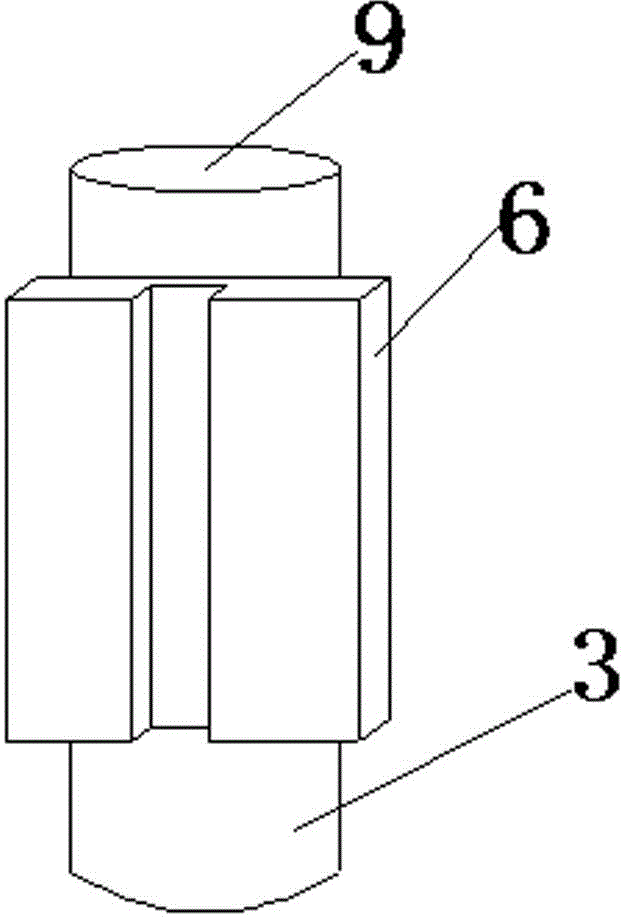

[0018] like figure 2 , 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com