Gear with oil sac and self-lubricating function

A technology of gears and oil bags, applied in the direction of belts/chains/gears, gear lubrication/cooling, components with teeth, etc., can solve problems such as inconvenience, inconvenience, and normal production of enterprises, so as to reduce maintenance and ensure normal order , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

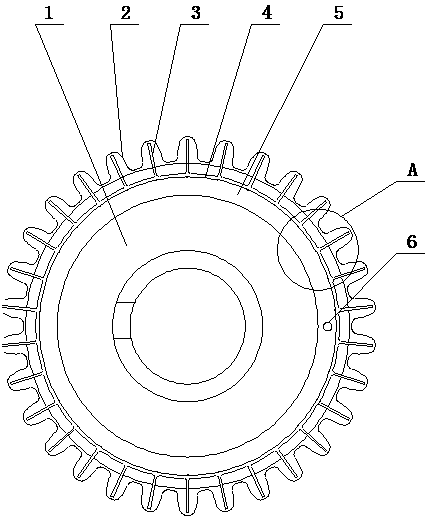

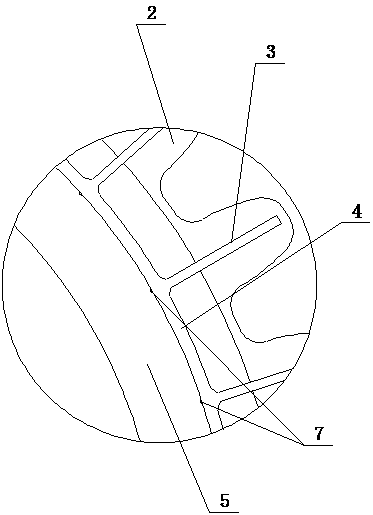

[0016] like figure 1 As shown, the self-lubricating gear with oil bag according to the present invention includes a gear body, and the gear body includes a wheel surface 1, and a plurality of outer gear teeth 2 are evenly arranged on the wheel surface 1 along its outer circumference. The inner side of the outer circumference of the wheel surface 1 is provided with an annular wheel groove 4; the inner side of the annular wheel groove 4 on the wheel surface 1 is provided with a matching annular cavity 5; Both are provided with a vertical groove 3 which communicates with the annular wheel groove 4 ; the outer circumferential wall of the annular cavity 5 is provided with a plurality of micro holes 7 which communicate with the annular wheel groove 4 .

[0017] An oil injection hole 6 is provided on the surface of the annular cavity 5 , and a hole cover is embedded in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com