A construction method for connection and replacement of glass fiber reinforced plastic sand-inclusion pipe and steel pipe for underground water supply

A technology of sand-filled pipes and glass fiber reinforced plastics, which is applied in the directions of pipes/pipe joints/fittings, pipe components, pipeline laying and maintenance, etc., which can solve the problem of poor pressure bearing capacity of glass fiber reinforced plastic pipes, blasting of glass fiber reinforced plastic pipes, and low efficiency of construction methods. and other problems to achieve the effect of improving construction quality, improving work efficiency, and improving the progress of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

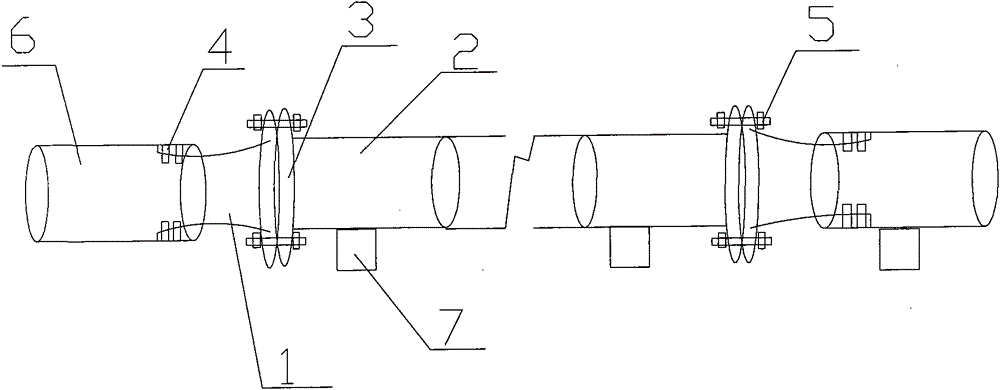

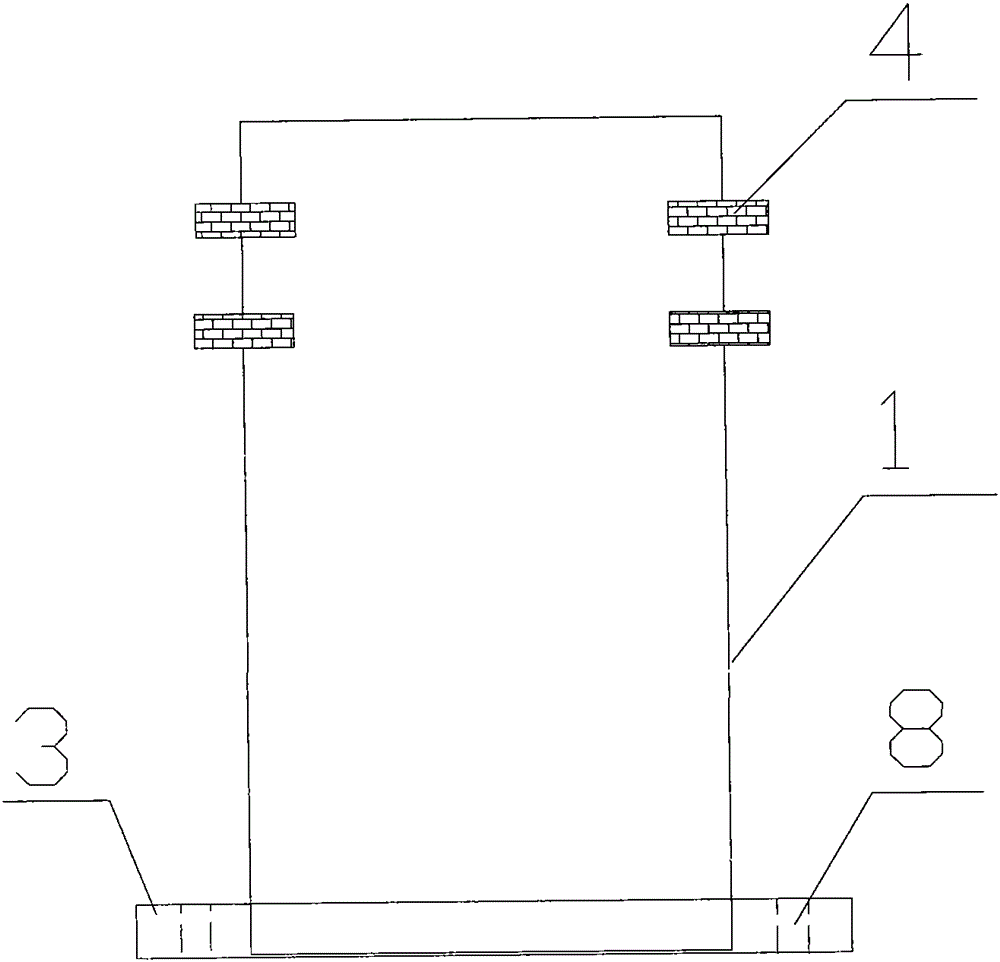

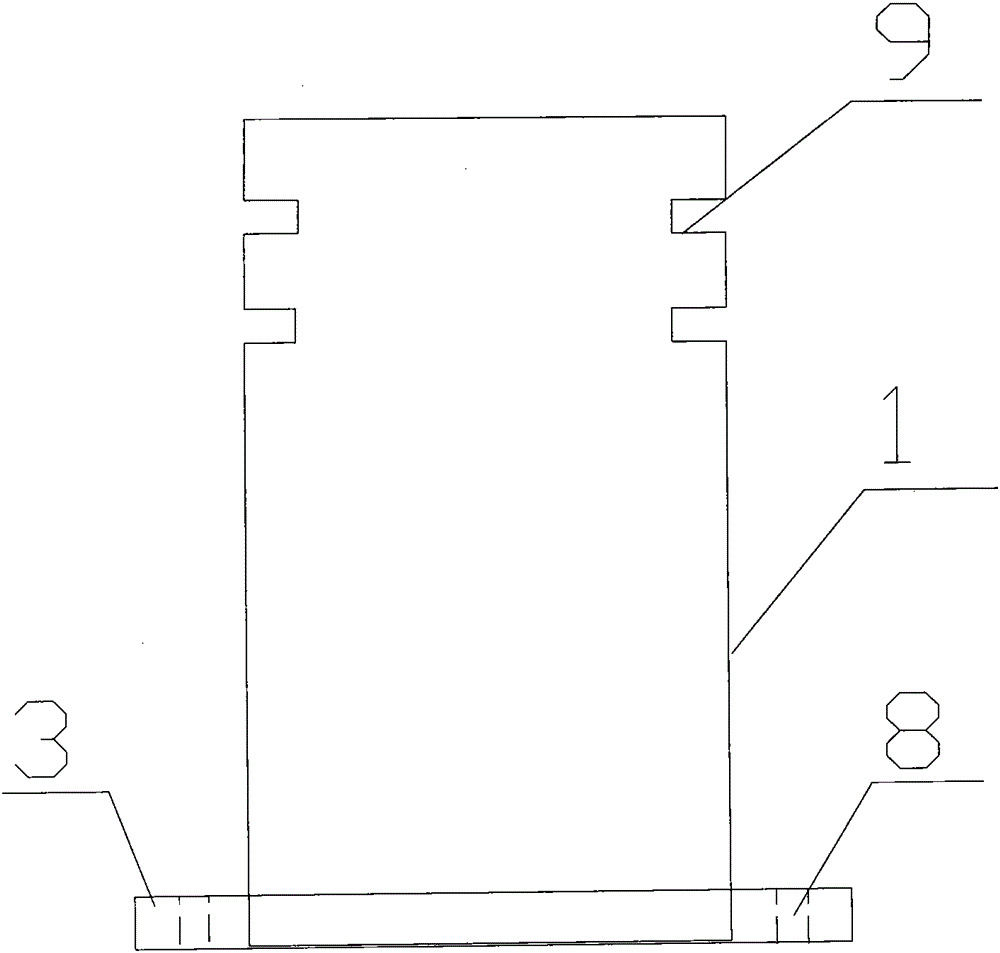

[0023] Such as Figure 1-7 As shown, a construction method for connecting and replacing an underground water supply FRP sand pipe and steel pipe, comprising the following steps:

[0024] 1) Preparation of materials and devices: According to actual needs, prepare two flange connection pipes 1, water supply steel pipe 2, reinforced concrete pier 7 and a number of backing plates with a thickness of 100mm and a specification of 1m×1m. One end of the two pipes is welded with a flange plate 3, and the inner wall of the other water supply steel pipe 2 is welded with two positioning steel plates 10 to prevent the butt joint misalignment of the steel pipe and the steel pipe. The flange connection pipe 1 has a flange plate 3 at one end and the water supply steel pipe The flange plate 3 of 2 is connected, and the outer wall of the other end is provided with a groove 9, and the groove 9 is filled with an elastic ring 4, and this end is inserted into a glass fiber reinforced plastic sand p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com