Pellet drying machine

A dryer and pellet technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problem of insufficient drying of pellet medicines, poor drying effect of pellet medicines, and effective drying area of drying ovens Small and other problems, to achieve the effect of simple structure, easy cleaning, high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

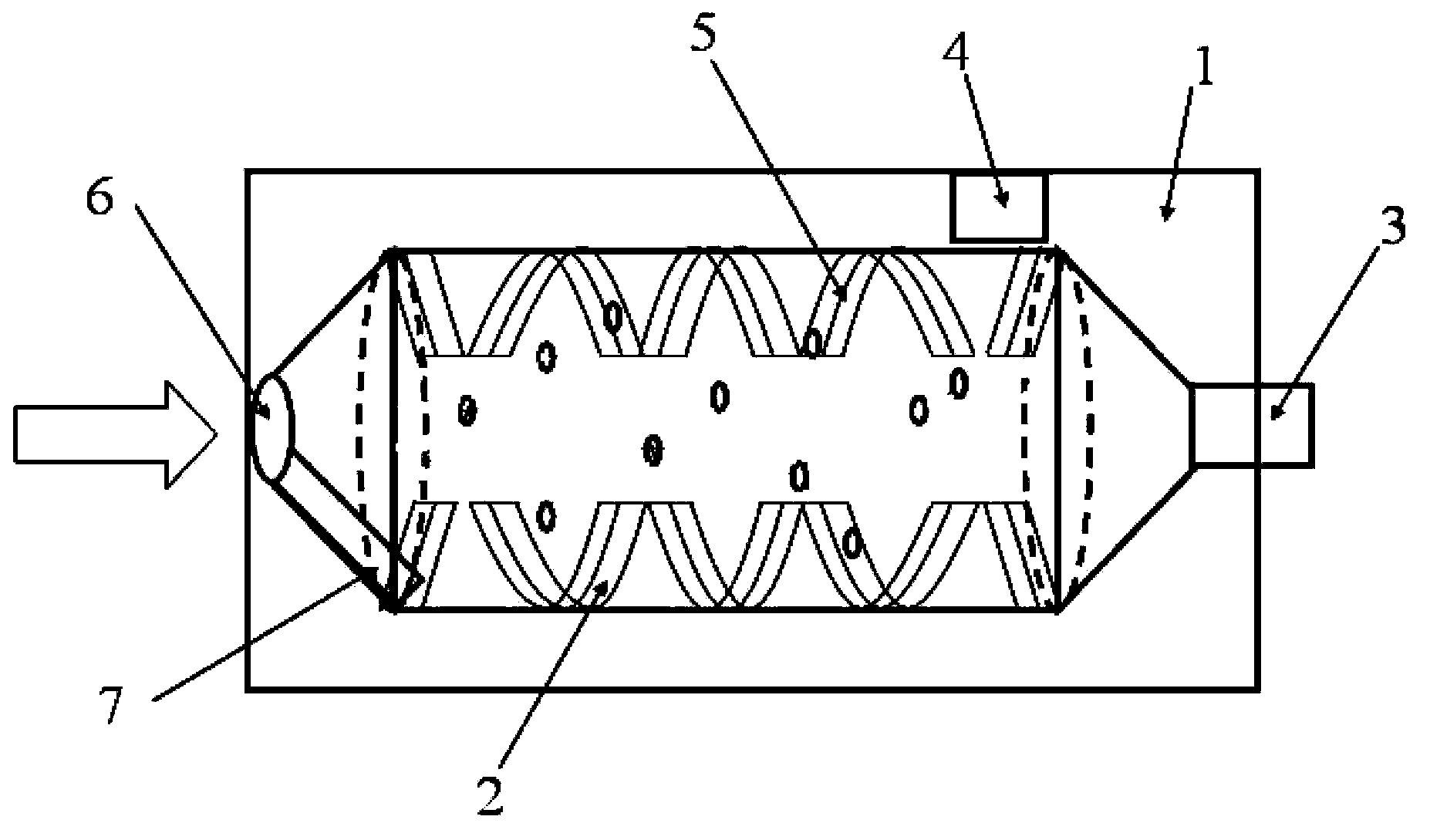

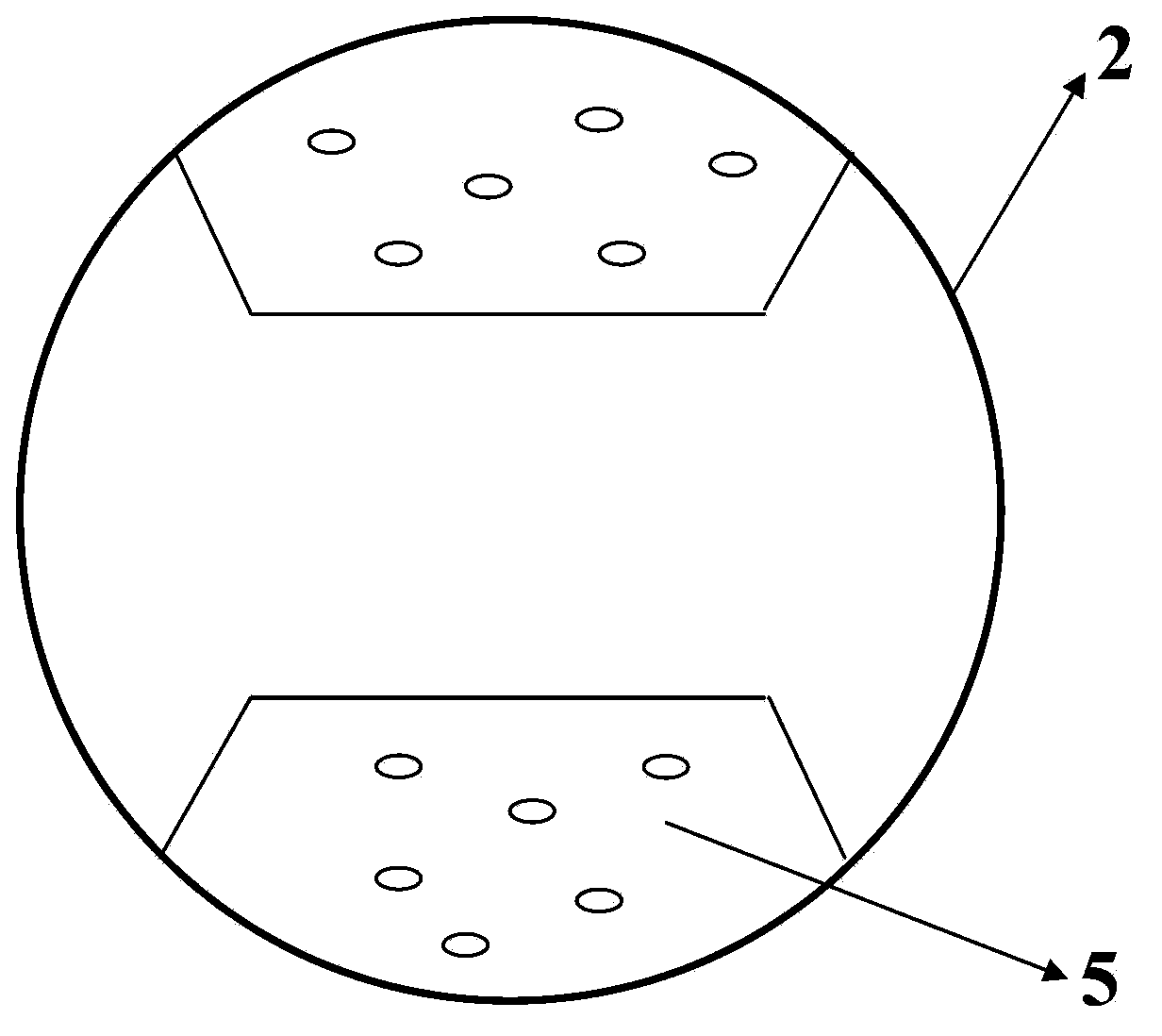

[0020] Such as figure 1 As shown, the present invention relates to a pellet dryer, a housing 1, a double-cone cylinder 2 inside the housing, a speed-regulating motor 3 and an electrical controller arranged at the rear end of the cylinder, and the induced draft fan is connected through a solenoid valve. At the rear end of the double-cone cylinder, the housing also has a heater, a temperature and humidity sensor, a dust removal system, and a dehumidification system. The wall has discontinuous double-layer blades 5 distributed in a bidirectional helical shape; the inside of the shell has an insulating layer, and the bottom of the shell is a porous structure; the double-cone cylinder is composed of a conical front section, a cylindrical middle section and a conical rear section. There is a material inlet and outlet 6 on the top, and the rear section is connected to the speed-regulating motor 3 through a connecting shaft, and there are several round holes or long holes on the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com