Moving-resistant level gage allowing connection line to be separated from shifting fork assembly

A technology of shifting fork assembly and material level gauge, which is applied to engine components, lubricating parts, engine lubrication, etc., can solve the problems that the shifting fork action axis and the system detection axis are not the same, the probability of failure is high, and the cost is high. The effect of reducing the randomness of the arm position, improving the reliability of electricity consumption and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

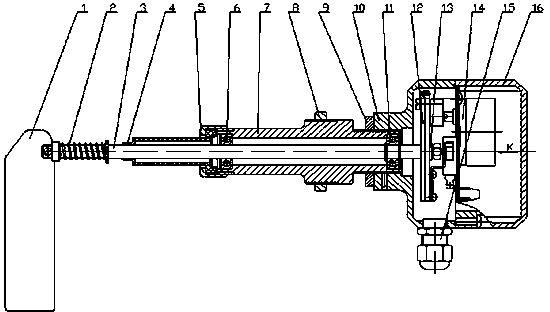

[0031] After the base 10 and the shaft cylinder 7 of the resistance-moving material level gauge of the present invention are screwed tightly, they are then locked with a lock nut 9 so that there is no relative movement between the two. Bearings 6, 11 are installed at both ends of the shaft cylinder 7, so that the detection shaft 3 and the shaft cylinder 7 can rotate freely. The detection shaft 3 is equipped with a shift fork assembly 12 at one end of the table seat, and the shift fork assembly 12 can rotate freely on the detection shaft 3 . Between the left shift fork 25 and the right shift fork 31, use the positioning piece 13 and use the tension spring to maintain the position between the two, and use the nut to insert the inner hole of the positioning piece 13 into the detection shaft 3, and there should be no firmness between them. relative movement. The other end of the detection shaft 3 is installed with a sealing rubber sleeve 4, put the knurled cap 5 on the sealing ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com