Method for judging uniformity of all batteries of lithium ion battery pack and timing voltage measuring instrument

A lithium-ion battery pack, timing measurement technology, applied in the direction of measuring current/voltage, measuring electricity, measuring electrical variables, etc., can solve the problems of insecure customer interests, high time cost, inconvenient capacity separation, aging batteries, etc. Achieve the effect of reducing production cost, improving quality, saving labor and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

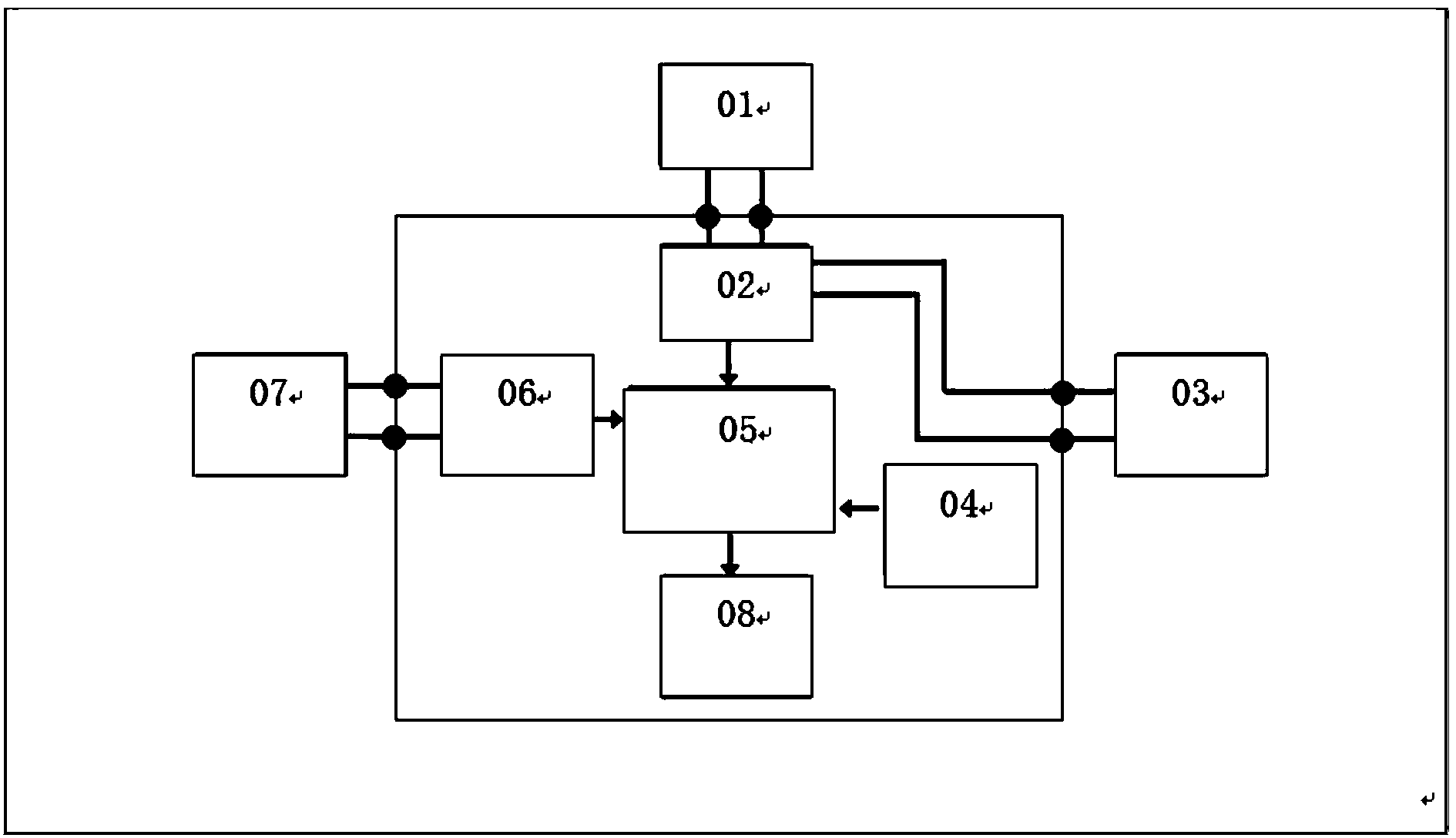

[0037] Example 1: figure 1 It is the principle diagram of the timing measuring voltmeter. The timing measuring voltmeter includes a charger module 01, a control conversion circuit module 02, a battery pack module to be measured 03, a timing time setting module 04, a central processing unit 05, a voltage stabilizing circuit module 06, a DC12V power supply module 07, and an output module 08. The central processing unit is a CPU. The central processing unit 05 is respectively connected with the timing setting module 04 , the output module 08 and the control conversion circuit module 02 . The timing time setting module 04 is used to set the time required for the voltage to stabilize after the discharge of the battery pack; the output module 08 performs data output or derivation; the control conversion circuit module 02 is used to receive the central processing unit The 05 instruction makes the battery pack to be measured switch between charging and voltage measurement modes, and...

Embodiment 2

[0039] Example 2: The 11585135Fe type soft-packaged lithium iron phosphate lithium ion 2P15S battery pack produced by our company has a nominal voltage of 48V (3.2V*15), a rated capacity of 20Ah, and the battery pack consists of 30 3.2V10Ah11585135Fe type soft-packaged lithium iron phosphate batteries And then 15 series combination.

[0040] The battery pack is tested according to the method of the present invention, and the specific operations are as follows:

[0041] (1) Processing and assembly of lithium-ion batteries: First, aging the battery cells according to the company's patent application number 201210094387.2, and the battery capacity and voltage are graded; secondly, according to the company's patent application number 201110186716.1 Matching group, and combined into a battery pack;

[0042] (2) Discharge: For the detected capacity of the assembled battery pack, the battery pack is charged to 50V, and then discharged to over-discharge protection, and the battery pa...

Embodiment 3

[0051] Example 3: The 26650Fe cylindrical steel case lithium iron phosphate lithium ion 3P5S battery produced by our company has a nominal voltage of 16V (3.2V*5) and a rated capacity of 9.9Ah. The battery pack is composed of 15 3.2V3.3Ah26650Fe cylindrical steel-cased lithium iron phosphate cells, first 3 and then 5 in series. According to customer requirements, the state of charge of the battery pack is 60% when it is shipped; the quality level of the battery pack is judged according to the method of the present invention, and the specific operations are as follows:

[0052] (1) Discharge: According to the customer's use conditions, the battery pack is discharged to BMS protection at a constant current of 0.2C, and connected to a timing measuring voltmeter before discharge;

[0053] (2) Measure the rebound voltage:

[0054] (3) Consistency judgment: According to the calculation formula of the rebound voltage regression equation established by our company, the rebound voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com