Light guide plate

A light guide plate and light technology, which is applied in the field of light guide plates, can solve the problems of insufficient luminance, the number and increase of complex backlight system components, etc., achieve the best luminance and uniformity, and improve the effect of luminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

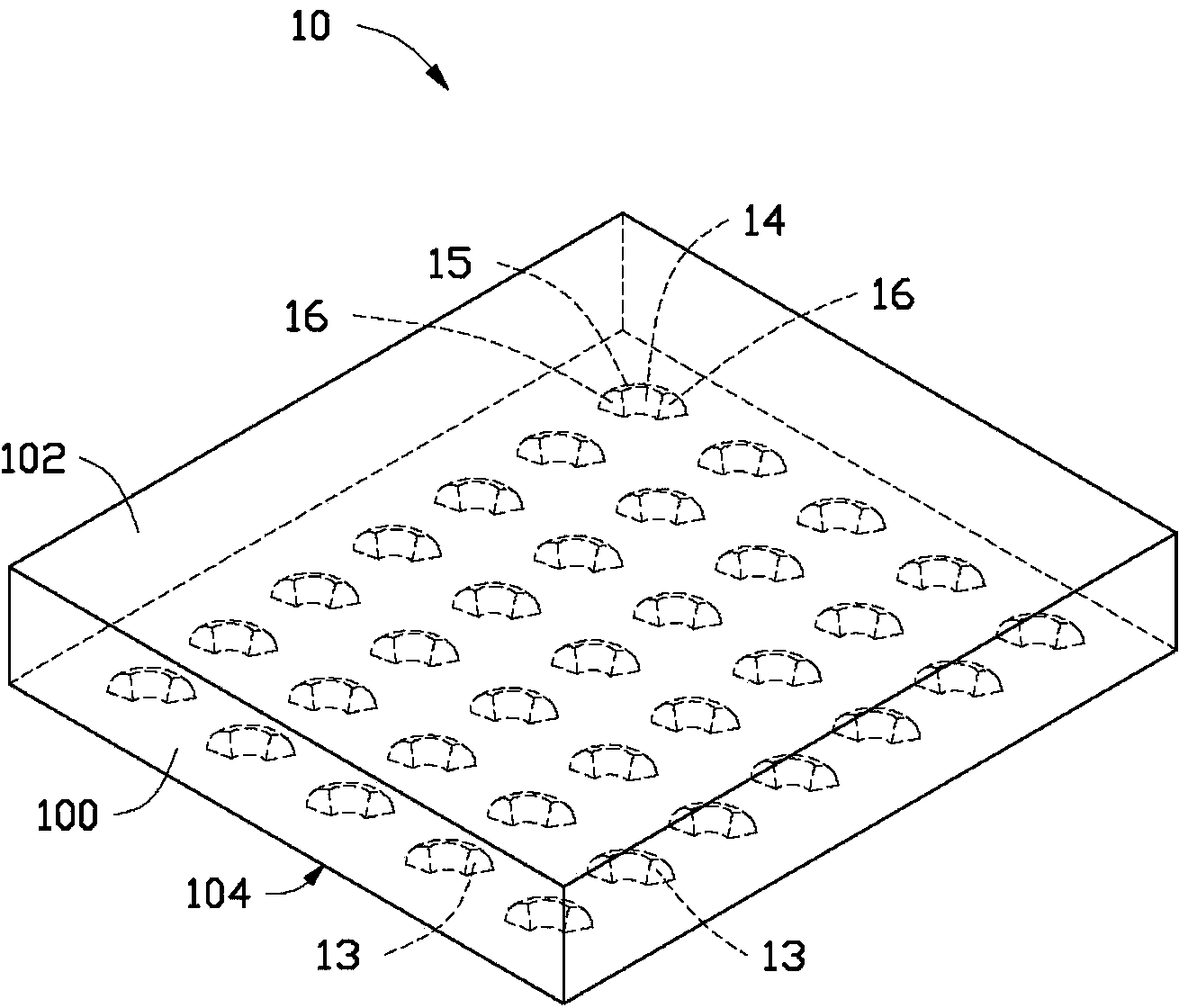

[0014] see figure 1 and figure 2 , a light guide plate 10 provided in an embodiment of the present invention includes a plurality of dots disposed thereon.

[0015] The light guide plate 10 is made of light-transmitting material, and includes a light-incident surface 100 , a light-exit surface 102 , and a bottom surface 104 opposite to the light-exit surface 102 .

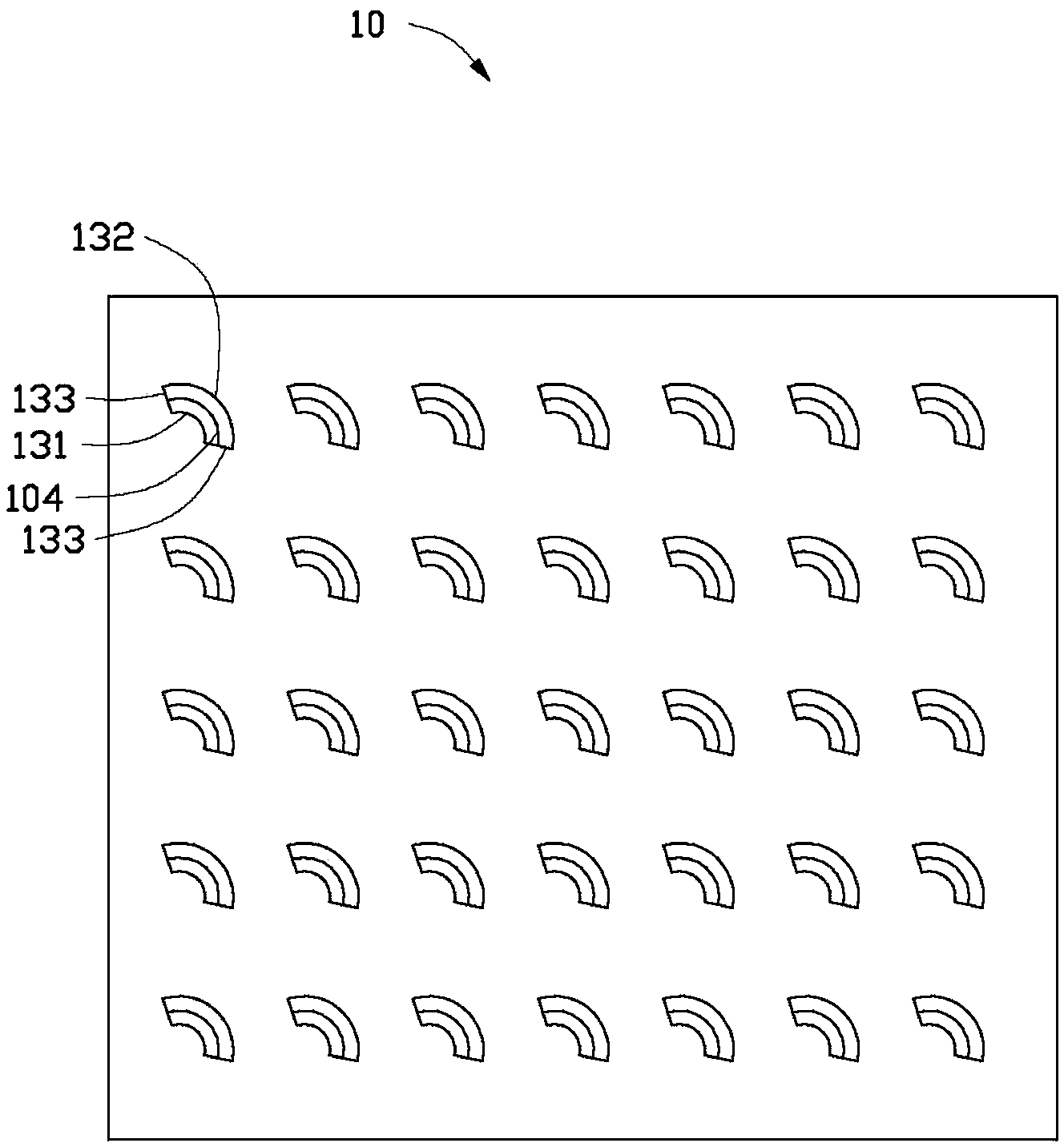

[0016] The dots are disposed on the bottom surface 104 for reflecting incident light thereon. In this embodiment, the dots are a plurality of depressions 13 formed on the bottom surface 104 .

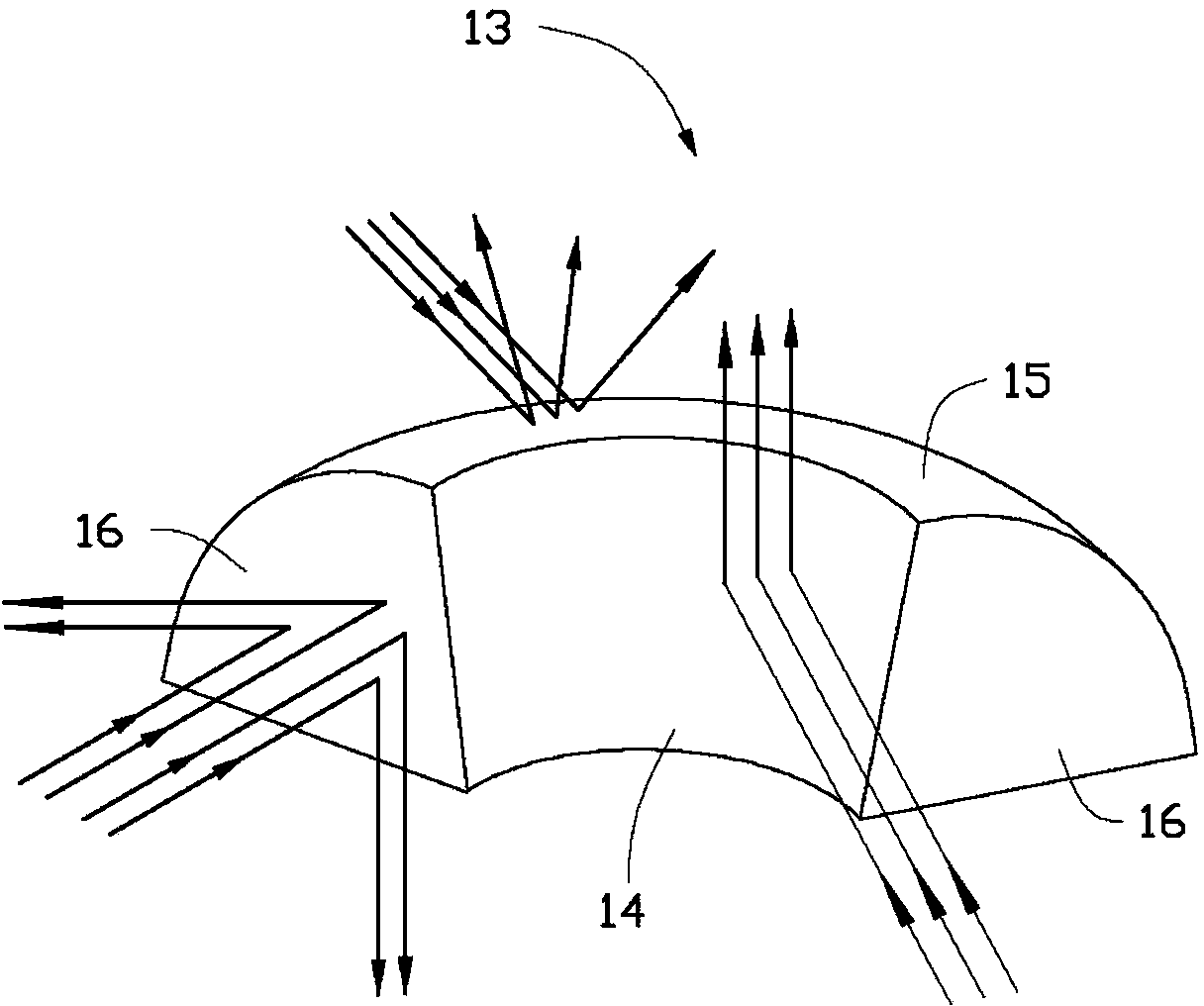

[0017] The opening formed by each depression 13 on the bottom surface 104 is fan-shaped, and the fan ring includes an inner arc 131 with a smaller radius, an outer arc 132 with a radius larger than the inner arc 131, and an outer arc 132 connecting the inner arc 131 and the outer arc 132. The two straight lines 133.

[0018] The four sidewalls of the recess 13 are a first curved surface 14 , a second curved surface 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com