Photosensitive resin composition for light blocking layer and light blocking layer using the same

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition for light-blocking layer and light-blocking layer using the same, can solve the problems of reducing optical density and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164] (Preparation of photosensitive resin composition for light-shielding layer)

[0165] A photosensitive resin composition for a light blocking layer was prepared using the following components.

[0166] (A) colorant

[0167] (A-1) Blue material

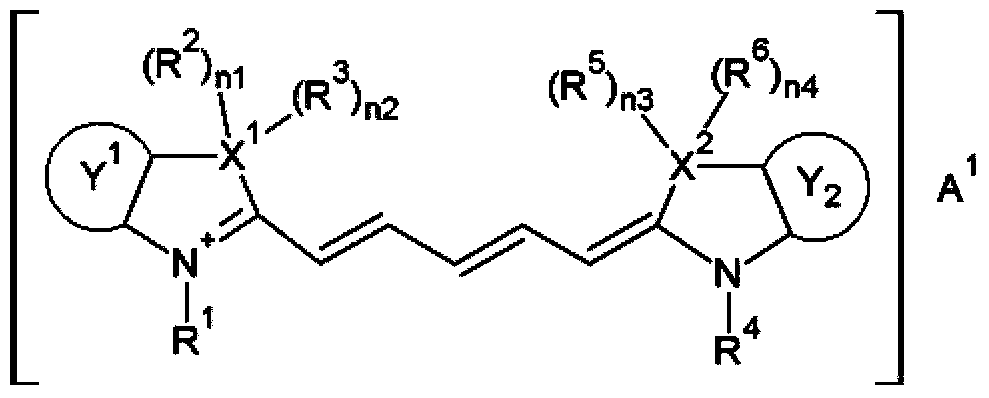

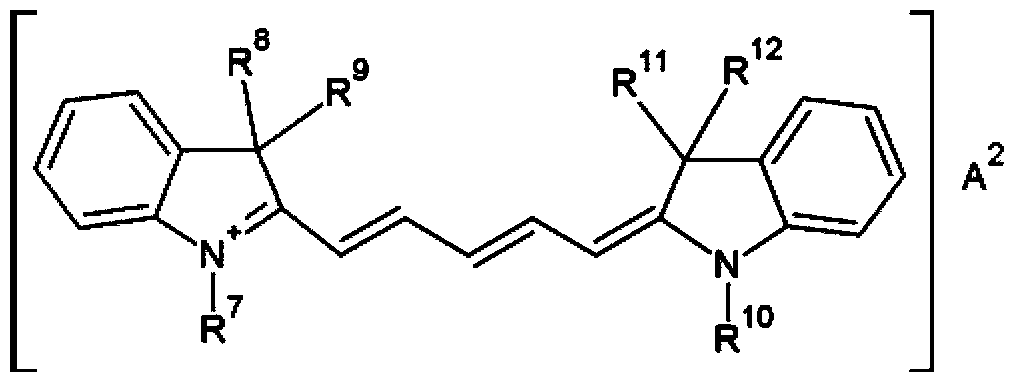

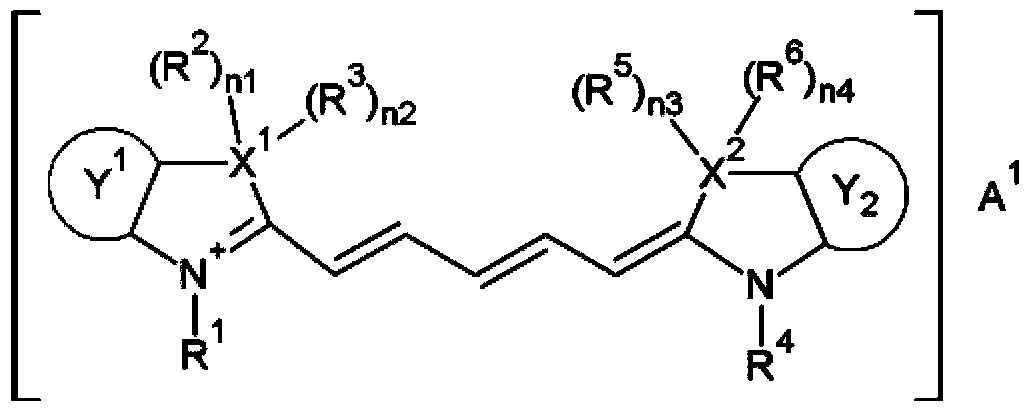

[0168] (A-1-1) A dye represented by the following Chemical Formula 4 (cyan-1, KISCO) was used.

[0169] [chemical formula 4]

[0170]

[0171] (A-1-2) A mill base (mill base) containing pigment V23 manufactured by BASF Corporation (Sakata Co., Ltd.) was used.

[0172] (A-1-3) A color paste (Sakata Co., Ltd.) containing Pigment B15:6 represented by the following Chemical Formula 18 and manufactured by BASF Corporation was used.

[0173] [chemical formula 18]

[0174]

[0175] (A-2) Red material

[0176] Orange 63 (Sakata Co., Ltd.) was used.

[0177] (B) Binder resin

[0178] As the cardo-based binder resin, V259ME produced by NSCC was used.

[0179] (C) Photopolymerizable monomer

[0180] Dipentaerythrito...

Embodiment 1 and 2 and comparative example 1

[0188]A photosensitive resin composition for a light blocking layer was prepared by mixing components according to the compositions provided in Table 1 below. Specifically, a photopolymerization initiator was dissolved in a solvent, and the solution was stirred for 30 minutes. Then, a binder resin and a photopolymerizable monomer are sequentially added thereto. The mixture was stirred for 1 hour. Then, the additives are added to the stirred mixture, and finally the colorant is added thereto. Stir the resulting mixture for more than or equal to 2 hours to prepare a photosensitive resin composition for a light-shielding layer.

[0189] (Table 1) (Unit: wt%)

[0190]

[0191] Evaluation 1: Elution of metal ions

[0192] Each of the photosensitive resin compositions for the light-shielding layer according to Examples 1 and 2 and Comparative Example 1 was coated with a thickness of 2.0 μm on the predetermined pretreated substrate, respectively, and then heated at 90° C. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com