Axial seal hoop quick-opening horizontal type deep sea simulation cabin

A technology of axial sealing and simulating cabin, which can be used in fluid tightness testing, simulation devices for space navigation conditions, simulators, etc. It can solve the problems of bending deformation of clamps, sealing failure, and reducing the sealing ability of O-ring rubber rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

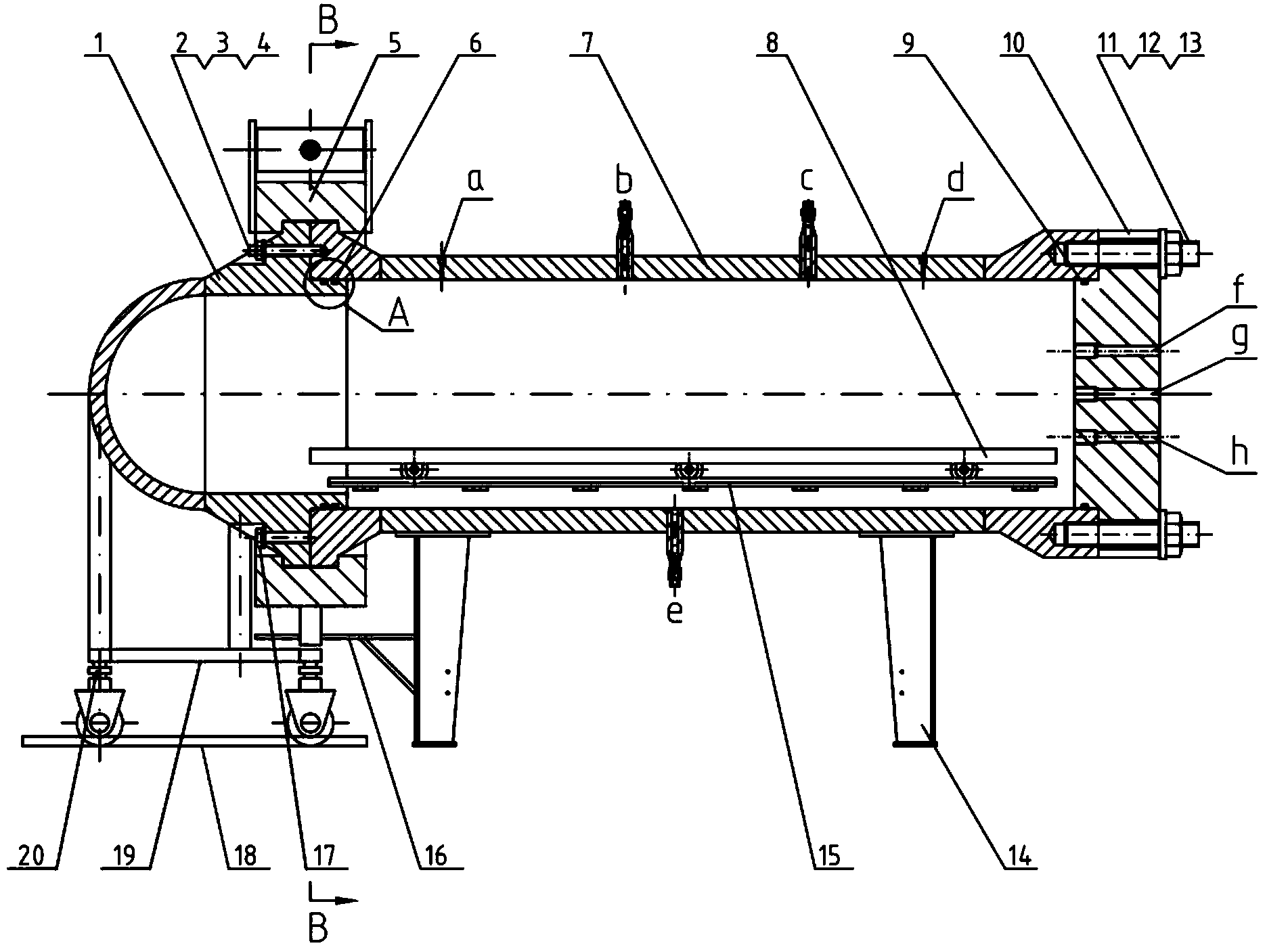

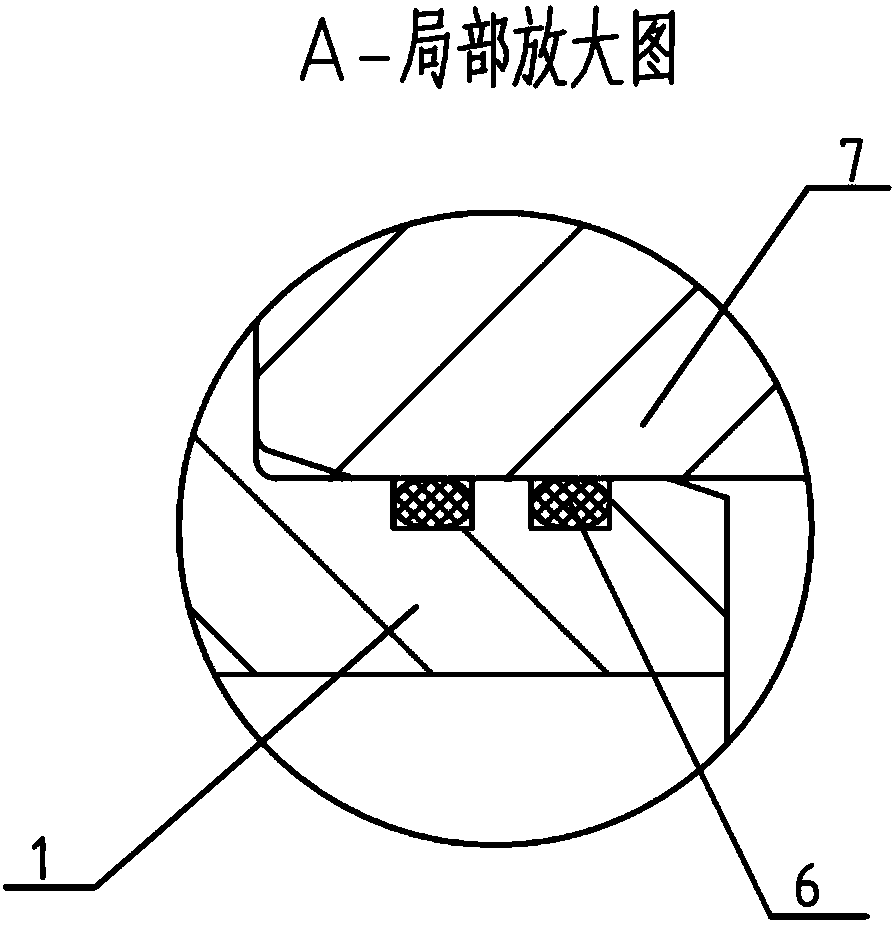

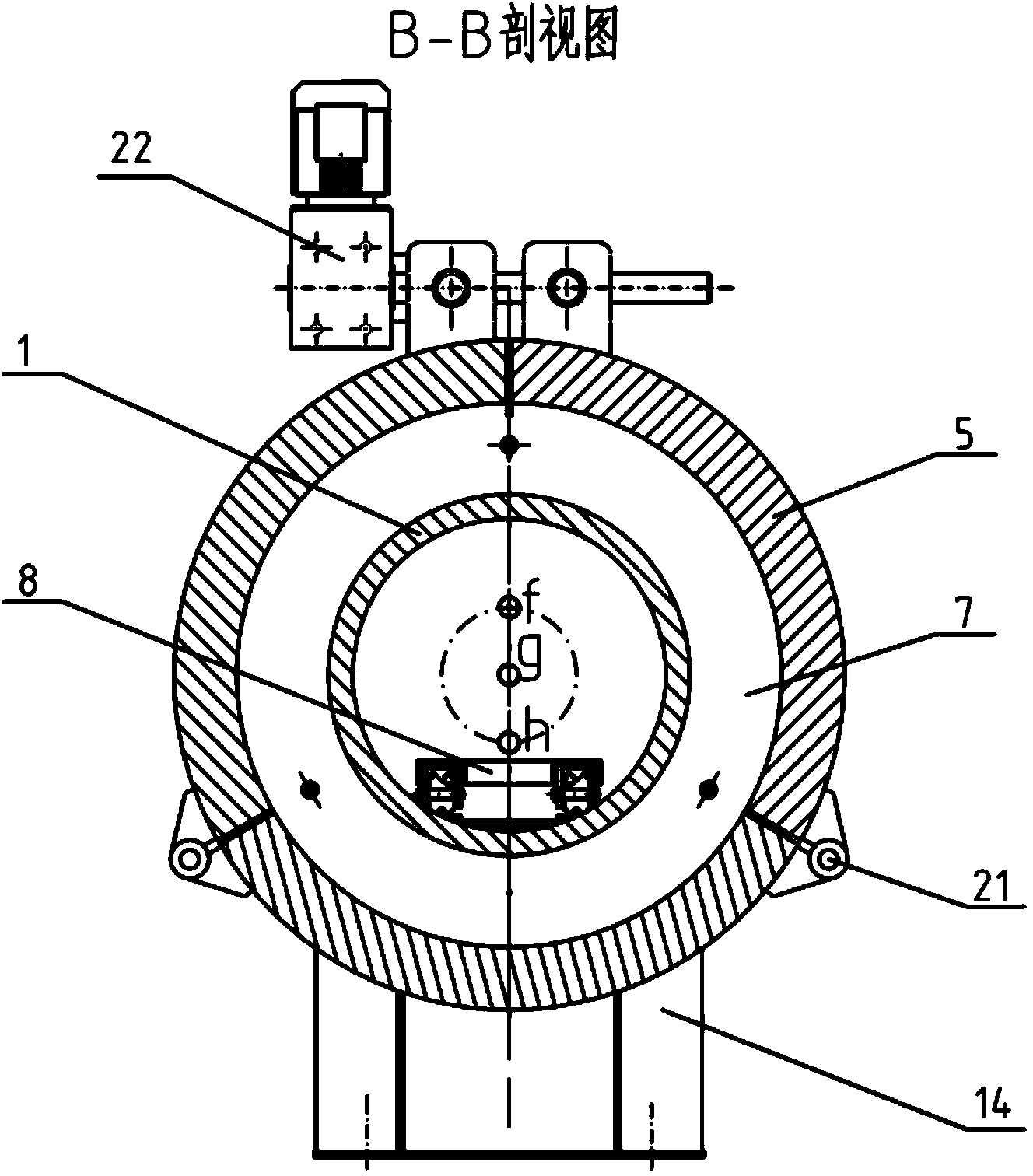

[0021] The specific implementation manner will be further described below in conjunction with the accompanying drawings. The present invention is mainly composed of a front end cover 1, a cylinder body 7, a rear end cover 10, a saddle 14, a circular clamp 5, and a clamp locking mechanism 22. The cylinder 7 is horizontally placed on the saddle 14, and the front end The cover 1 and the rear end cover 10 are respectively connected to the head and tail ends of the cylinder 7. The cylindrical front end cover 1 is supported by a moving frame 19. The height of the moving frame 19 can be adjusted by adjusting the height of the screw rod 20. To move is guided by guide rail 18, so just can guarantee that the center line of front end cover 1 and the center line of cylinder body 7 are on the same straight line.

[0022] One end of the front end cover 1 is welded by a spherical head. There is an annular protrusion on the middle outer wall, and an annular step protrudes from the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com