Vertical type high pressure full-automatic backwashing filter

A fully automatic, backwashing technology, applied to fixed filter element filters, gravity filters, filtration separation, etc., can solve the problems of discontinuous filtration process, unguaranteed cleaning quality, and poor filtering effect, achieving good cleaning effect, Alleviating maintenance difficulties and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

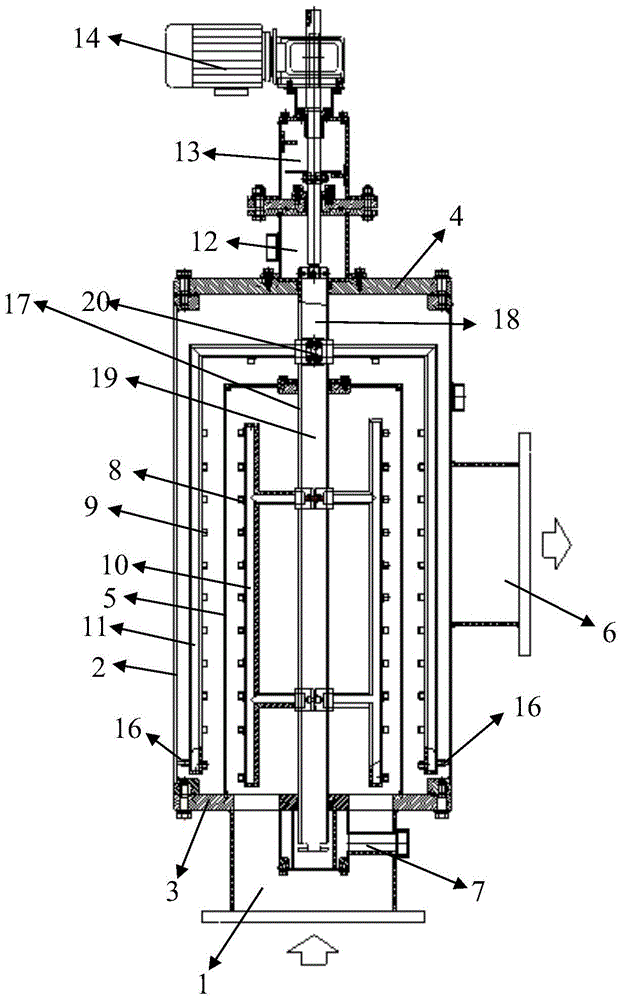

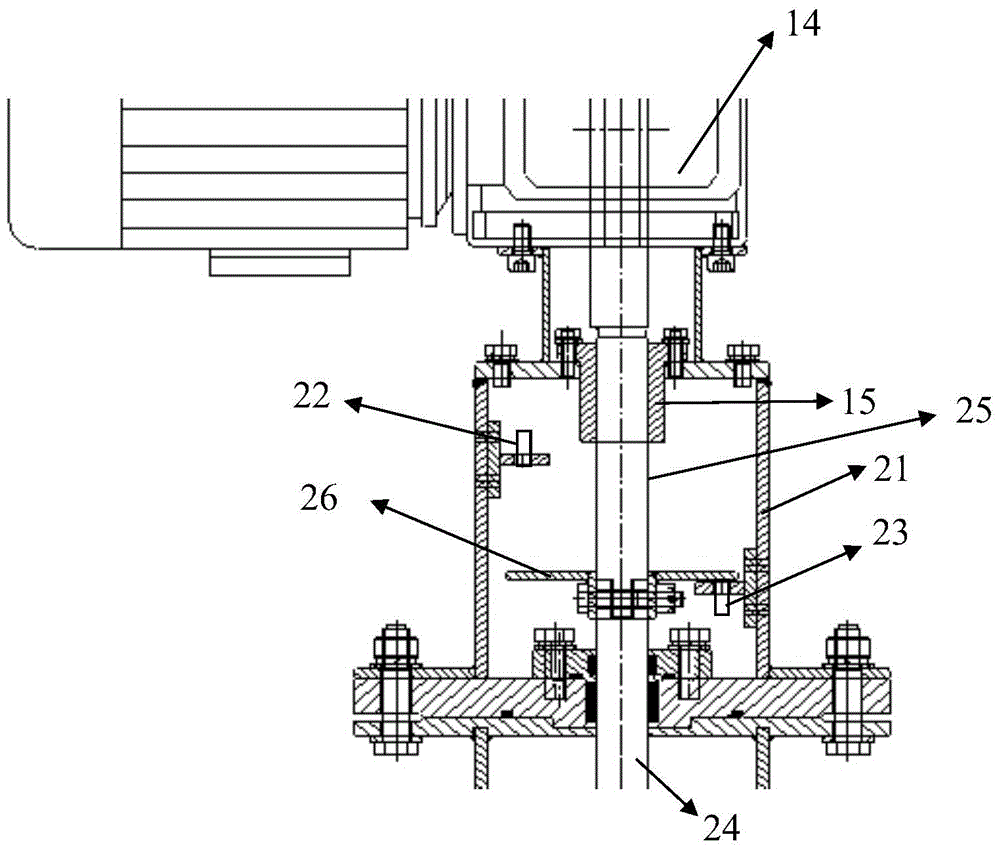

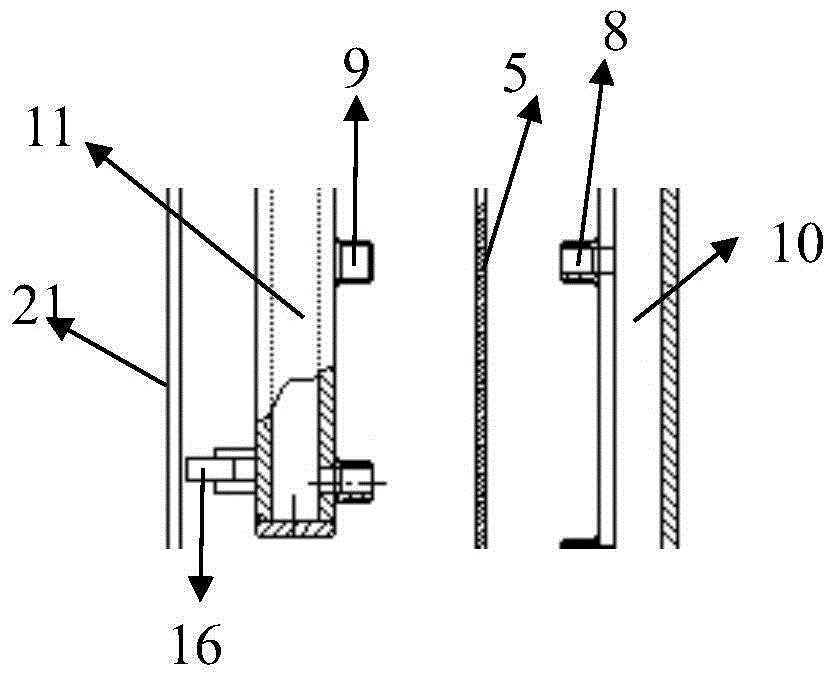

[0019] As shown in the figure, a vertical high-pressure automatic backwash filter includes a liquid inlet 1, a cylinder body 2, a front cover 3, a rear cover 4, a filter 5, a liquid outlet 6, and a sewage chamber 7. The filter screen 5 is distributed in the cylinder body 2 in a cylindrical structure. Four cleaning branch pipes 11 are evenly distributed on the outside of the filter screen 5. There are cleaning nozzles 9 on the cleaning branch pipes 11. The inside of the filter screen 5 is correspondingly provided with four suction pipes. Dirty branch pipe 10 has dirt suction nozzle 8 on the dirt suction branch pipe, and there are many groups of dirt suction nozzle 8 and cleaning nozzle 9, which are installed in parallel on the inside and outside sides of filter screen 5. The cleaning branch pipe 11 and the sewage suction branch pipe 10 are all communicated with the central rotating shaft 17, and the central rotating shaft 17 is a hollow pipe, which is divided into a sewage pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com