An automatic frequency-variable-amplitude vibration device and vibration adjustment method thereof

A variable-amplitude vibration and automatic technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as high current impact, achieve the best efficiency and effect, high efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

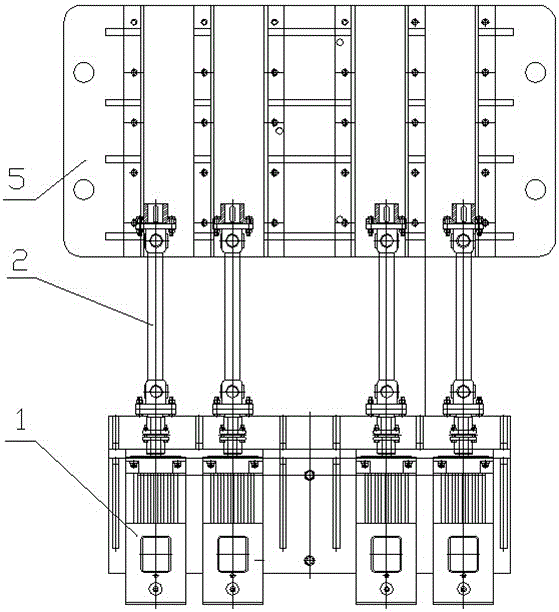

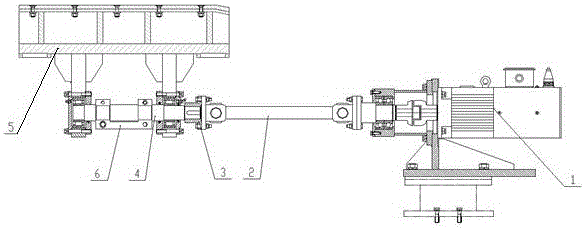

[0032] An automatic variable frequency and amplitude vibration device, such as figure 1 and figure 2 As shown, it includes a servo motor 1, the output shaft of the servo motor 1 is connected to the transmission shaft 2, and the other end of the transmission shaft 2 is connected to the vibration shaft 4 through a coupling 3, and the vibration shaft 4 is fixed under the vibration table 5 through a bearing and connected to the vibration table. 5 keep parallel in the horizontal direction, the eccentric block vibrator 6 is set on the vibration shaft 4, the number of servo motors 1 is an even number and at least four, and the two servo motors 1 in the middle form a group, and the servo motors 1 on both sides are One group, the two groups of servo motors 1 are distributed side by side, and the two servo motors 1 in each group start synchronously, with the same rotational speed and opposite directions.

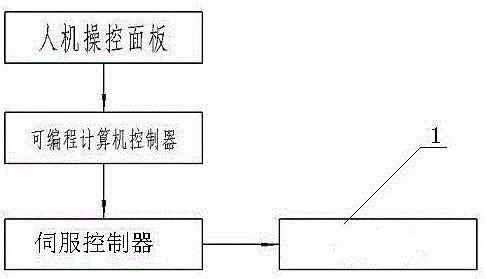

[0033] Also includes electronic control systems such as image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com