Automotive radiator grille decorating electroplated bright strip assembling structure

An assembly structure and radiator technology, applied in radiators, vehicle parts, transportation and packaging, etc., can solve the problem of inability to guarantee product surface appearance and commercial performance, affect product assembly accuracy and fit clearance, self-tapping screw mounting columns are easy to break, etc. problems, to achieve the effect of ensuring the commercial performance of the appearance, benefiting the mass production of the mold, and improving the mold processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

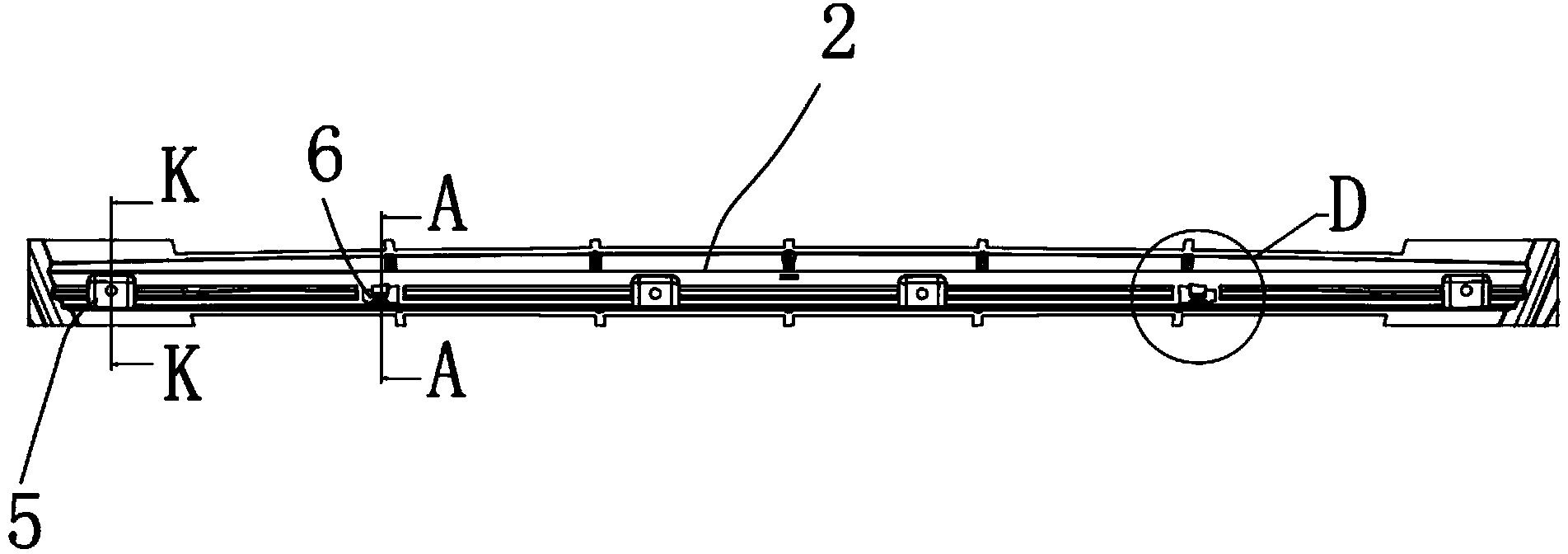

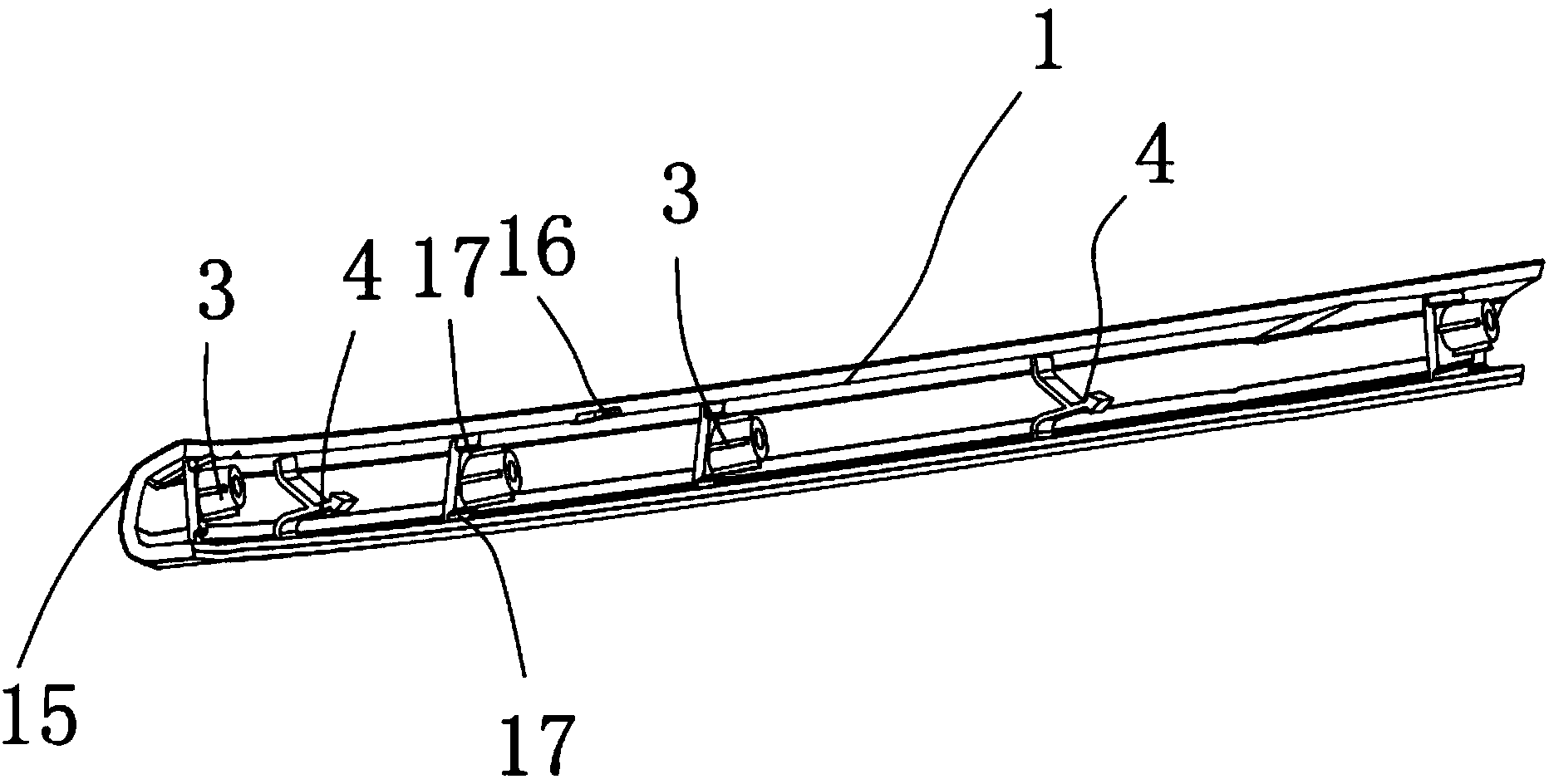

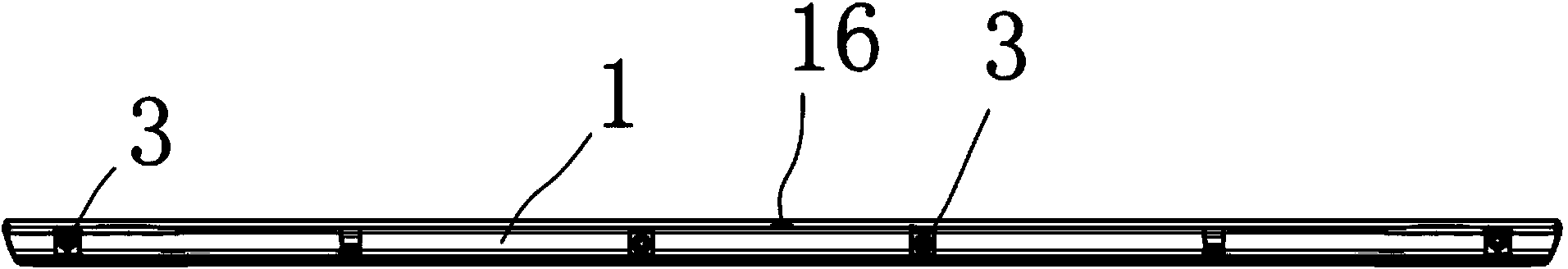

[0032] In the figure, bright strip body 1; grille body 2; self-tapping screw mounting column 3; claw 4; locking piece 5; insertion groove 6; insertion part 6a; extension connection part 6b; thickening part 7; thinning part 8 ; Inclined sheet body 9; anti-shrinkage tank 10; rib body 11;

[0033] Such as figure 1 , figure 2 , image 3 as well as Figure 9 As shown, the automotive radiator grille decoration electroplating bright strip assembly structure includes a bright strip body 1 and a grille body 2, and a plurality of self-tapping screw mounting columns 3 and two There are four claws 4, here there are 4 self-tapping screw mounting columns 3, and the locking piece 5 matched with the screw mounting column and the inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com