Carton unfolding device of automatic packaging machine

An automatic packaging and machine-opening box technology, applied in packaging and other directions, can solve problems such as sensor misjudgment, cartons that cannot be opened, and the impact of the drug feeding process, and achieve the effects of avoiding interference, high precision, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

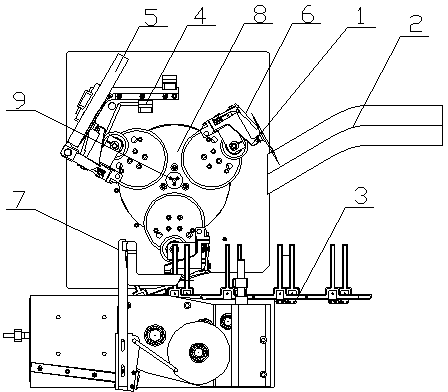

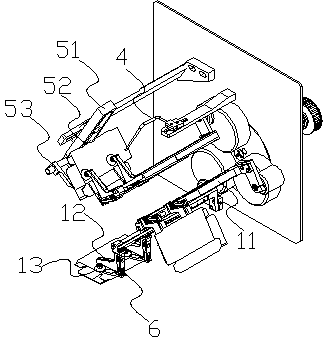

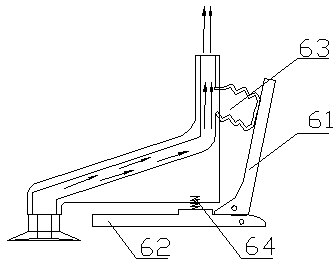

[0033] As shown in the figure, an automatic packaging machine box opening device is set between the carton warehouse 2 and the carton conveying chain 3, including the suction claw assembly 1, the box opening striker 4, the pre-opening box assembly 6, and the box opening assembly 5 , Excessive box opening assembly 7, transmission assembly 8, vacuum control assembly 9.

[0034] The transmission assembly 8 includes a sun gear 81 and three first planetary gears 82 evenly distributed on the outer periphery of the sun gear 81. The first planetary gears 82 are serially connected to the planet carrier and connected to the sun gear 81 via a synchronous toothed belt 84. Transmission, the transmission ratio of the sun gear and the first planetary gear is 1:3, and the outer side of the first planetary gear is provided with three evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com