Single arm carton shaping device

A molding device and carton technology, applied in packaging and other directions, can solve the problems of the carton being unable to be smoothly formed, inaccurate transportation in place, inconvenient operation for customers, etc., to reduce labor costs and maintenance costs, The overall structure is reasonable, and the effect of solving many processes is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

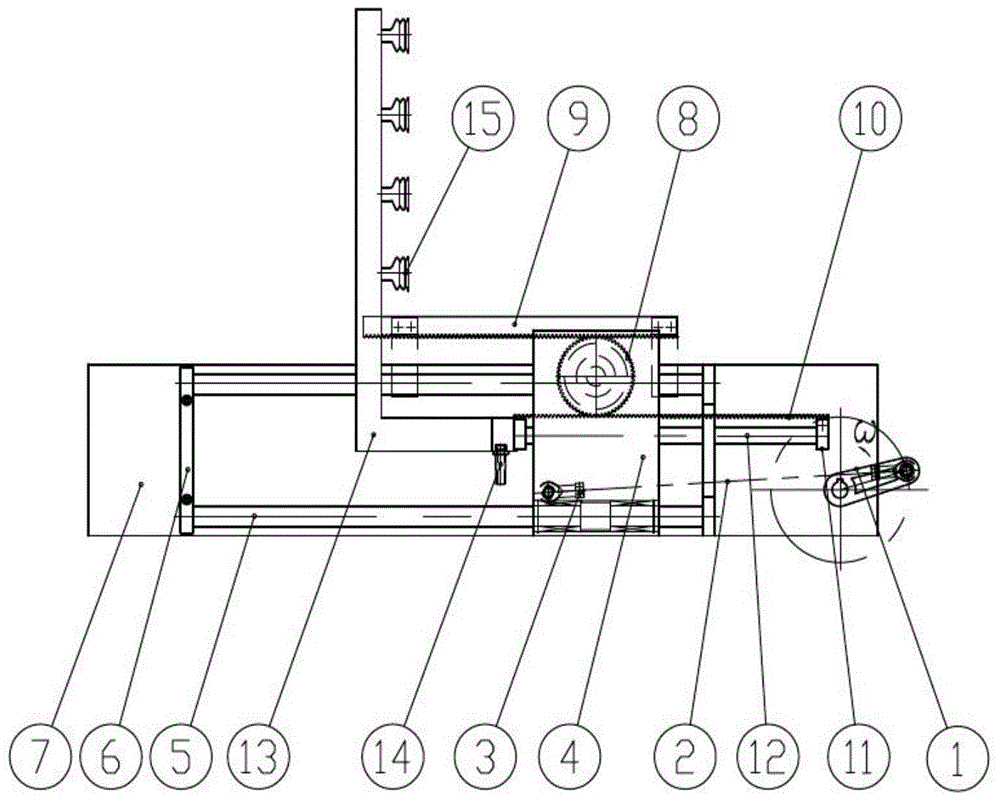

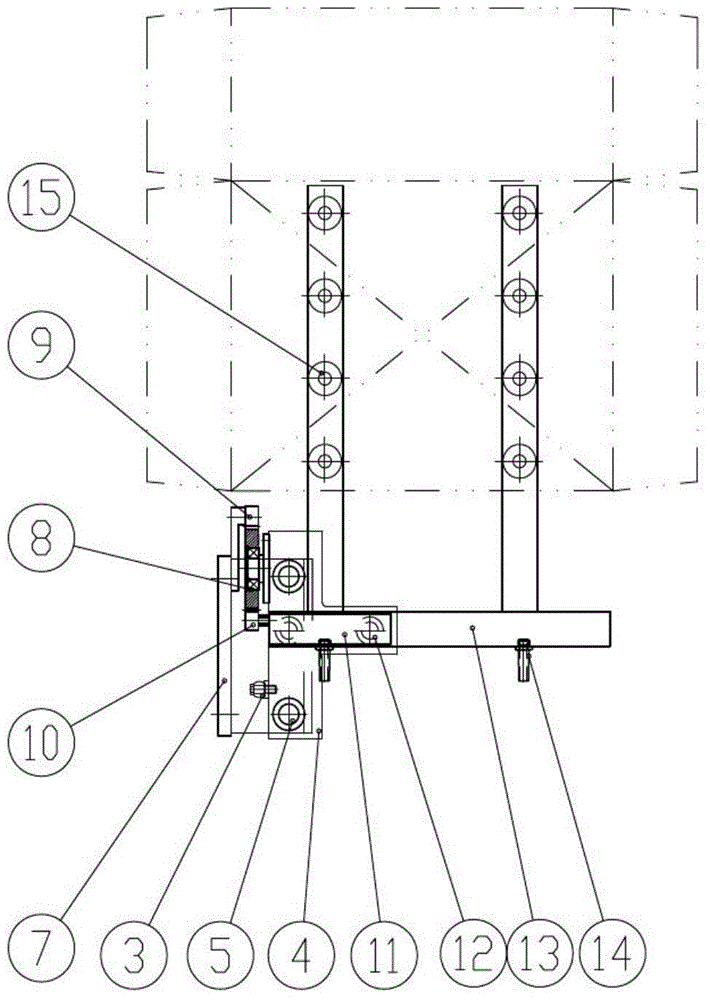

[0012] The structure of the present invention is further described in conjunction with the accompanying drawings: the single-arm carton forming device shown in the figure is composed of a connecting rod driving slider mechanism, a rack and pinion stroke multiplication mechanism and a suction arm assembly. The swing arm 1 is driven by a geared motor, and is connected with the slider 4 through the joint bearing 3 and the connecting rod 2 to form a link-driven slider mechanism. The guide shaft 5 is connected with the fixed seat 6 and fixed on the bottom plate 7 to form a linear movement channel of the slider. The gear 8 is fixed on the slider 4 through the bearing seat, and meshes with the upper rack 9 and the lower rack 10 simultaneously to form a stroke amplification mechanism. The upper rack 9 is fixed on the bottom plate 7, and the lower rack 10 forms a linear movement channel through the fixed block 11, the guide shaft 12, and the slider 4. The suction arm 13 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com