Automatic one-dimensional-equilibrium adjusting lifting tool for spacecraft

An automatic adjustment, spacecraft technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of non-reusable, low assembly accuracy, difficult to guarantee assembly quality, etc., to improve the level of assembly automation, adjustable bearing range , The effect of high-precision assembly and disassembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

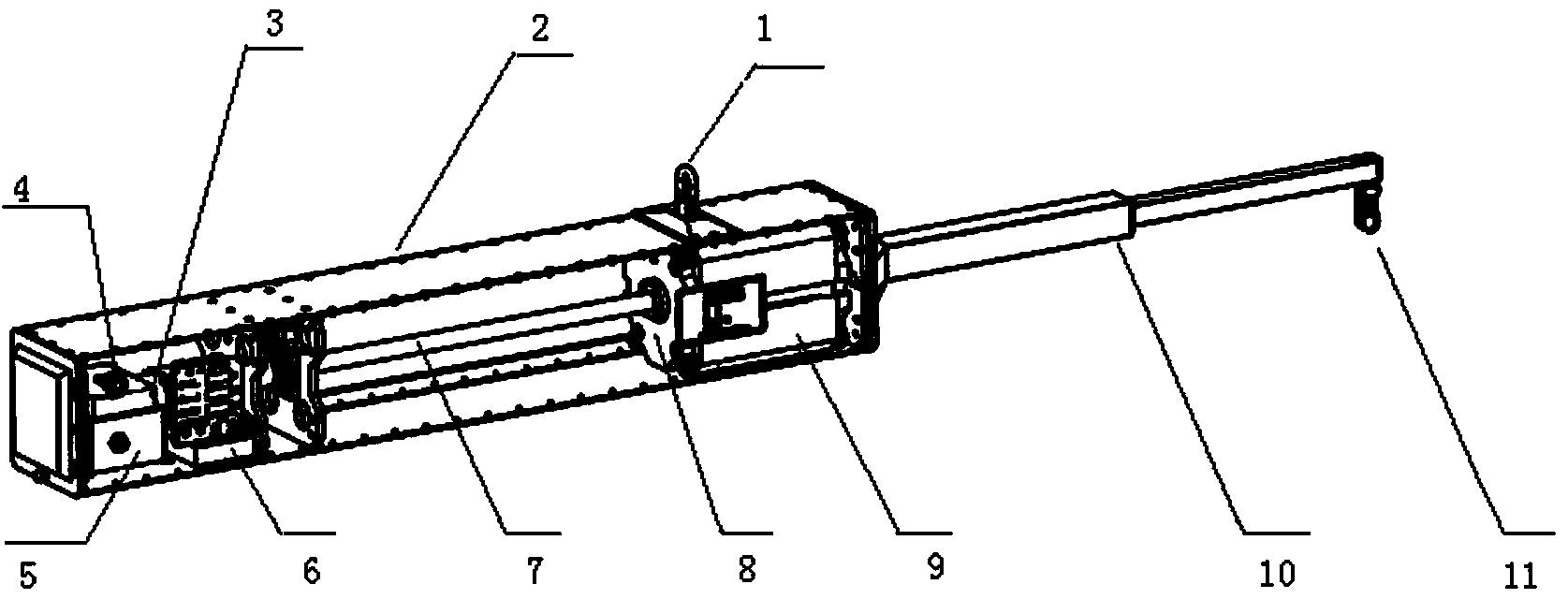

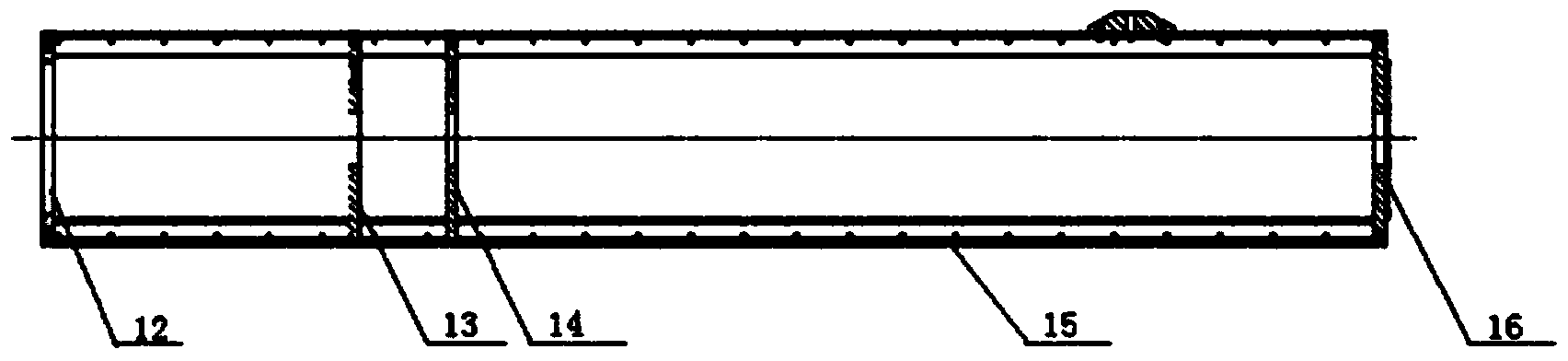

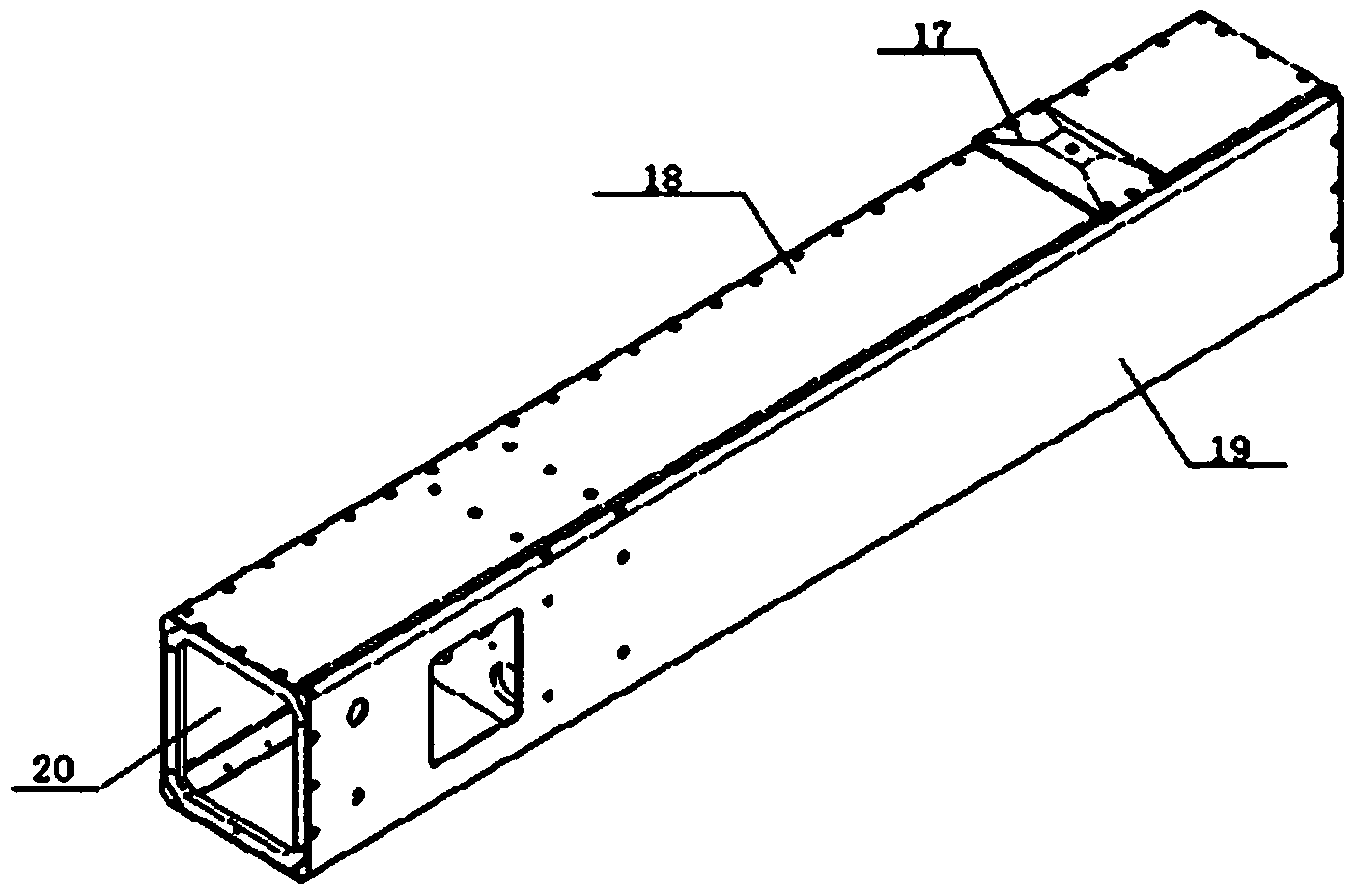

[0023] Such as figure 1 As shown, the hanger includes a rotating ring assembly 1, a main hanging beam 2, a control module 3, a main switch 4, a power supply 5, a driving motor 6, a ball screw 7, an inclination sensor 8, a counterweight moving mechanism 9, a probe Auxiliary suspension beam 10, tension sensor and suspension ring assembly 11. The suspension ring assembly 1 is arranged on the upper end of the main suspension beam 2, and the crown block is articulated by the suspension belt. The tension sensor and the suspension ring assembly 11 are installed at the load in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com