A Method of Detecting Wear Pointer Using Internal Gear Coupling

A technology of internal meshing gears and couplings, applied in belts/chains/gears, spring mechanisms, transmission parts, etc., can solve the problems of difficult inspection, high labor intensity of maintenance workers, and difficult inspection and judgment. Demonstrate the effect of technological progress and avoid major equipment safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

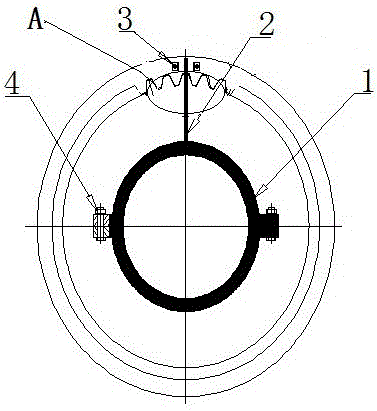

[0025] 1) Basis for gear wear:

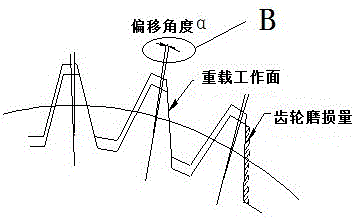

[0026] After the ring gear matched with the reel ring gear wears out, there will be a certain gap. During the operation of the reducer, a certain tooth of the low-speed output shaft of the reducer is used as the reference. It will deflect at a certain angle during the loading process. It is calculated through the corresponding relationship between the angle and the arc length. The ratio of the radii of the pitch circles is equal, (in the case of a small offset, the arc length can be regarded as a straight line), so the wear amount of the gear can be calculated.

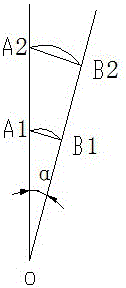

[0027] 2) Calculation of gear wear amount: After the ring gear of the reel ring gear is worn out, it will deflect at a heavy load. When the deflection angle α is a certain value, the arc lengths corresponding to different radii Calculated by formula:

[0028] A1B1=OA1*A2B2 / OA2

[0029] In the formula: the value of OA1 is equal to 1 / 2 of the diameter of the pitch circle of the meshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com