Slotted air film cooling structure for guide blades of turbines

A technology of turbine guide vane and air film cooling, which is applied to stators, engine components, machines/engines, etc., can solve the problems of processing technology and manufacturing cost control, the impact of high temperature components on aerodynamic performance, and reduce engine efficiency, etc., to achieve high cooling. Efficiency, improving efficiency, reducing the effect of aerodynamic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

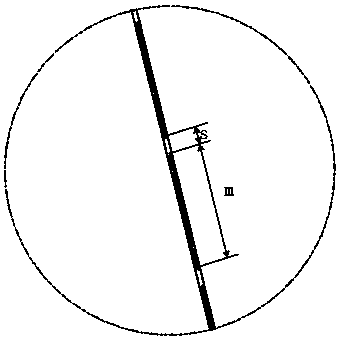

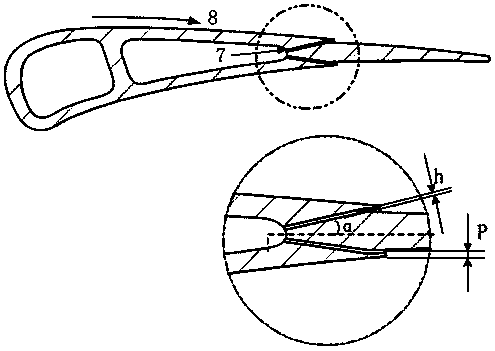

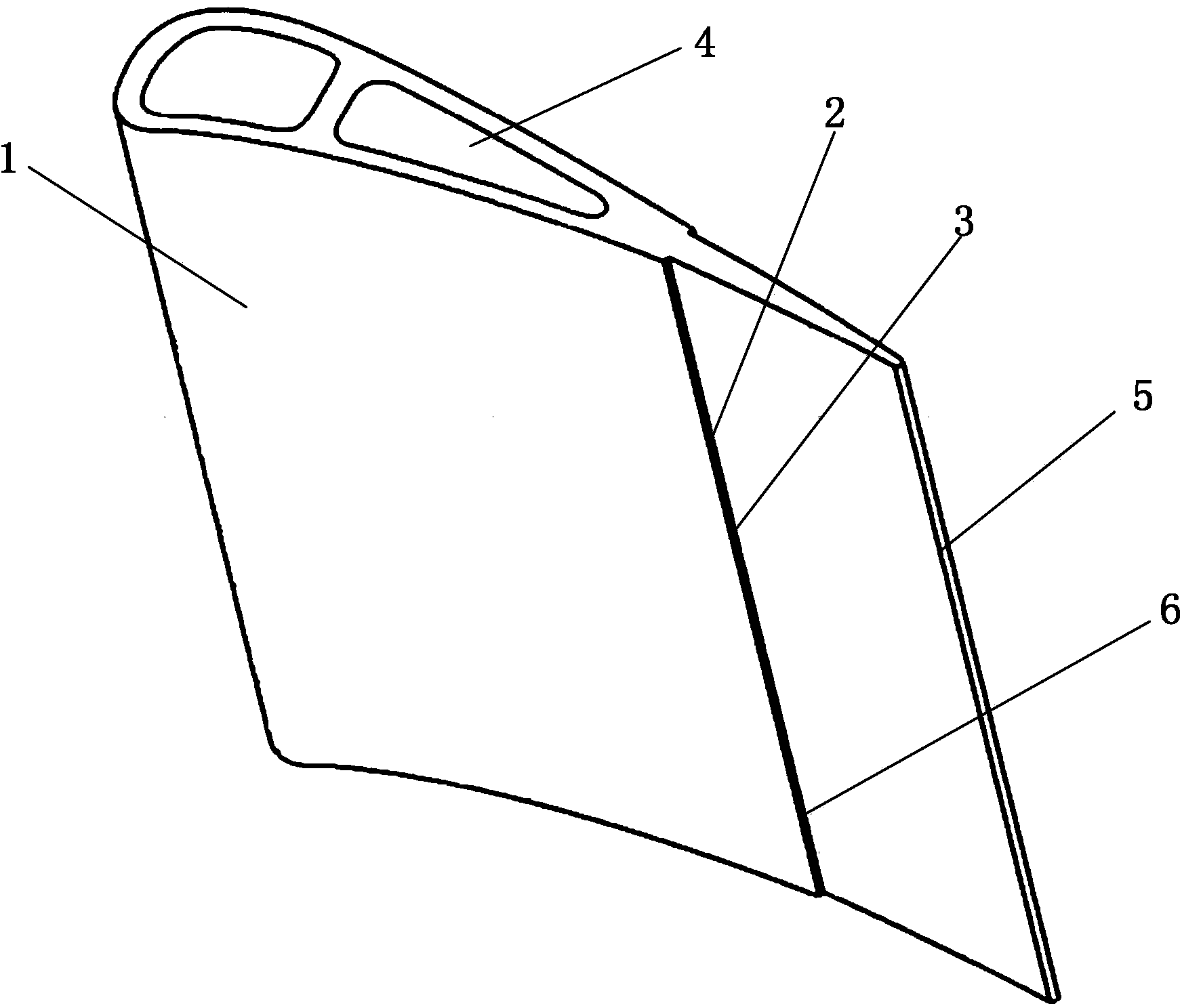

[0012] refer to figure 1 , 2 As shown, the present invention is a novel film cooling structure suitable for a turbine guide vane of a gas turbine engine. The biggest feature of the novel film cooling structure is that the conventional film cooling holes are replaced by film slots (2). The blade base (1) has two exhaust film slits (2), which are respectively opened on the suction surface and the pressure surface of the blade. The air film slit (2) is an oblique slit forwardly inclined at an angle (α) along the mainstream direction, (α ) ranges from 30° to 40°, the air film slit (2) communicates with the tail cold air cavity (4), and is arranged at equal intervals along the blade height direction, and its outlet is located at a distance of 1 to the blade chord length from the blade tail edge (5) / 3 of the stepped surface (6), the height (p) of the stepped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com