Diagonal flow plate type direct air-cooling condensation water energy dissipation device

An energy-dissipating device and condensate technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of pipeline support system damage, condensate drop potential energy can not be ignored, etc., to reduce impact force and reduce energy concentration The effect of releasing and reducing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

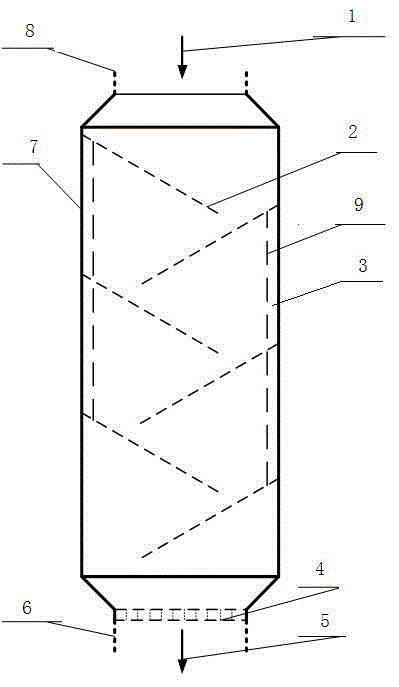

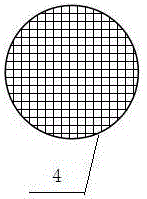

[0022] See attached figure 1 , A diagonal flow plate type direct air condensing water energy dissipation device, which includes an energy dissipation cylinder 7 (also called a condensate efficiency device body). The upper mouth of the cylinder 7 is connected with the original upstream pipe 8 of the condensate, The lower port of the cylinder 7 is in communication with the original downstream pipeline 6 of the condensate, and the cylinder 7 can also adopt devices of other shapes. The outlet position of the cylinder 7 is provided with a condensate flow sharing plate 4, and the condensate flow sharing plate 4 has a porous structure. The aperture on the condensate flow sharing plate 4 gradually decreases from the center of the circle.

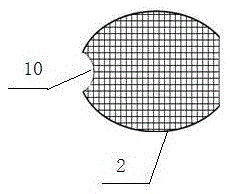

[0023] See attached figure 2 , The inner wall of the cylinder 7 is provided with a plurality of obliquely placed baffles 2 that can reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com