Energy saving and environmental protection four-drive power machine

An energy-saving, environmentally friendly, power machine technology, applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of difficult to guarantee vertical accuracy, poor stability of the body, and difficult construction, and achieve simple structure, improved stability, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

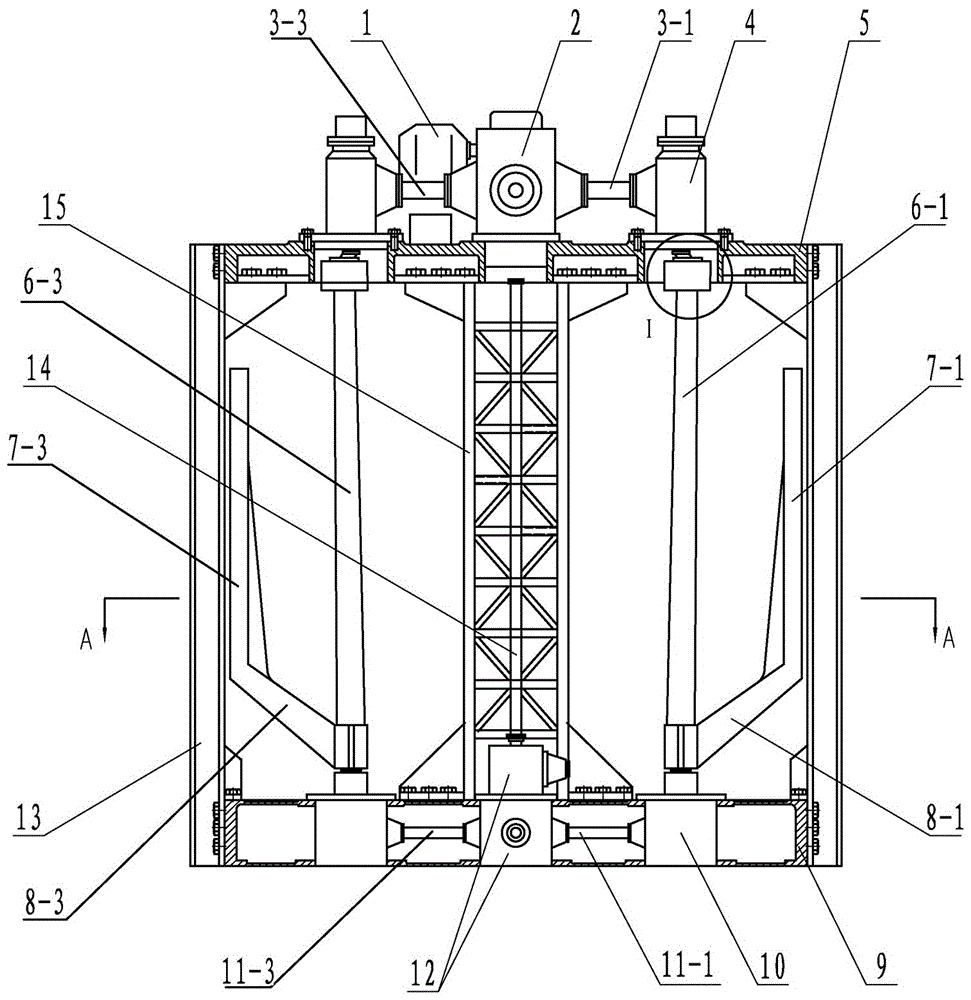

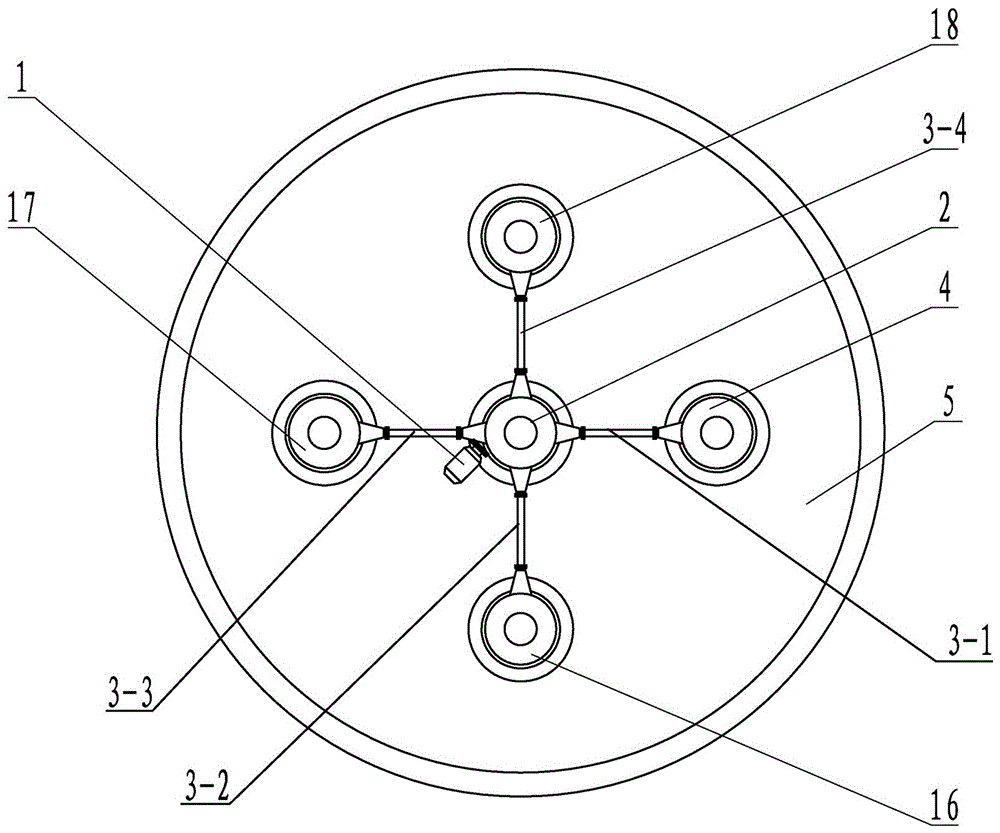

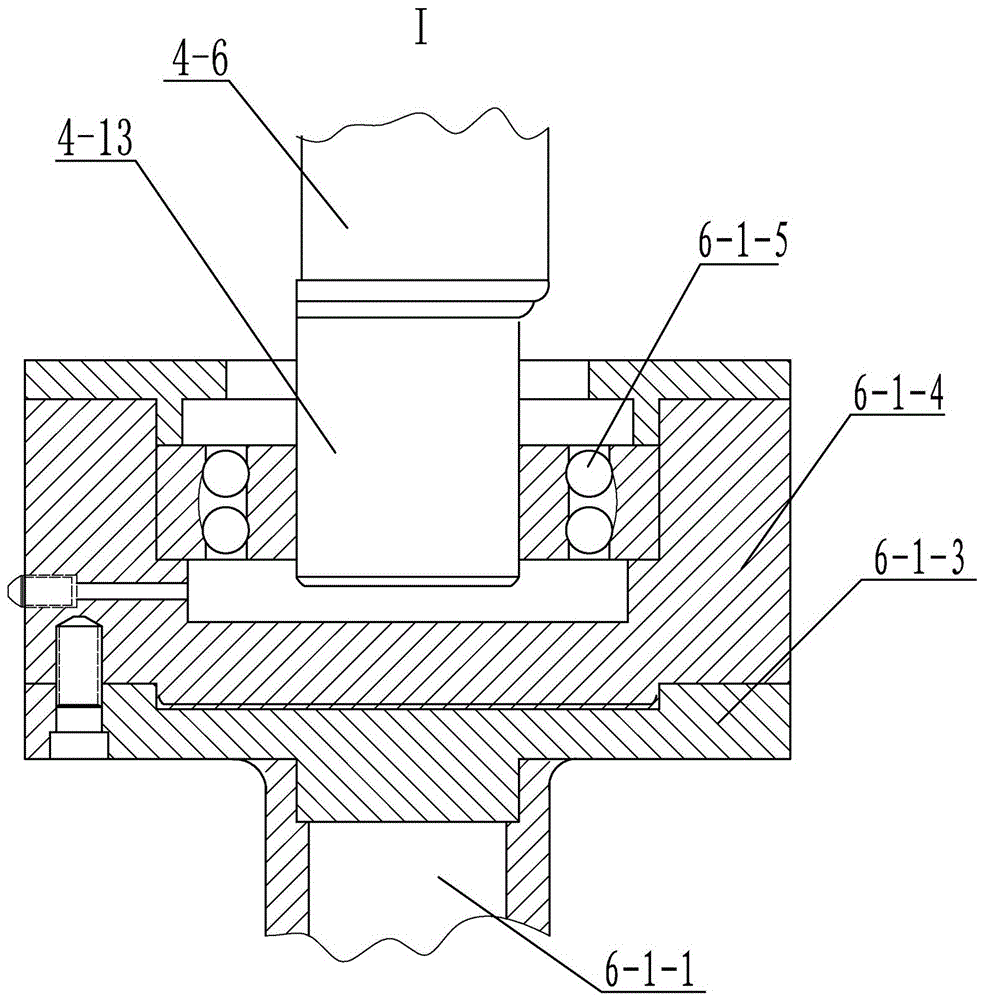

[0053] Depend on Figure 1-8 It can be seen from the shown embodiment 1 that it includes the total power and transmission mechanism, four linkage extensions, four-machine linkage power output and transmission mechanism 12, synchronous adjustment mechanism and frame;

[0054] The total power and transmission mechanism includes a variable speed DC motor 1, the total power distribution and transmission mechanism 2 and the first to fourth extension power transmission shafts 3-1~3-4; the total power distribution and transmission mechanism 2 includes a worm 2-2, turbine 2-3, turbine drive shaft sleeve 2-17, first driving large bevel gear 2-22, four first driven small bevel gears 2-27, first to second ratchet mechanism and first Bevel gearbox 2-11;

[0055] The first driving large bevel gear shaft 2-1 is vertically installed in the first bevel gear box 2-11 through a bearing, and the turbine 2-3 is installed on the top of the first driving large bevel gear shaft 2-1 through a bearin...

Embodiment 2-3

[0102] The difference between embodiment 2-3 and embodiment 1 is the eccentric distance of the first eccentric shaft 4-6, the height of the first lever vertical shaft 6-1, the height and weight of the first counterweight, and the radius of rotation of the first counterweight. Parameters are different, and above-mentioned each parameter among the embodiment 2-3 is as following table:

[0103]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com