Temperature-difference power conversion method

A technology of power conversion and power conversion system, which is applied in the directions of mechanisms, machines/engines, and mechanical equipment that generate mechanical power to achieve the effects of simple structure, cost control, and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

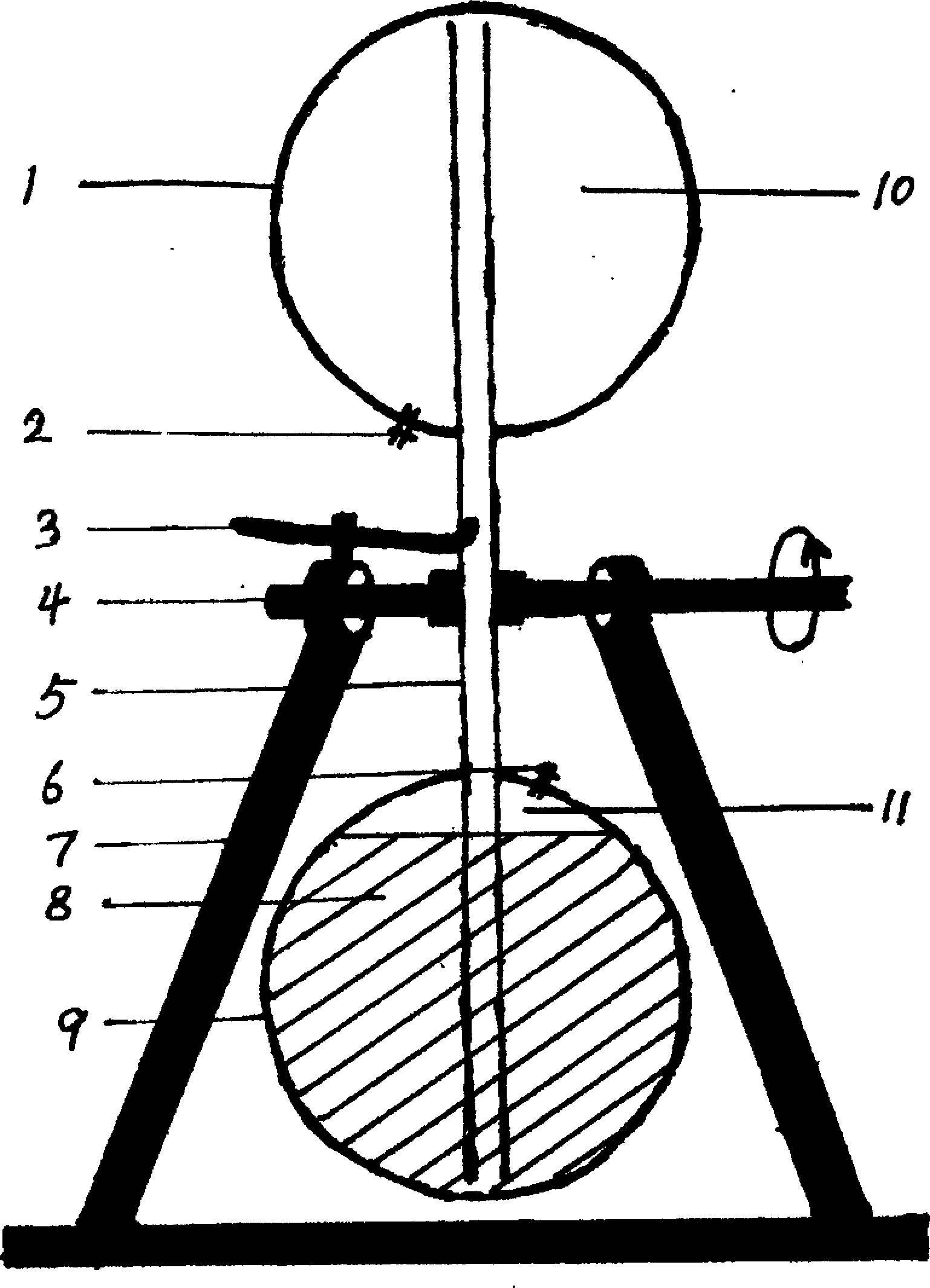

[0010] The method invention will be further described below in conjunction with the accompanying drawings.

[0011] The attached drawing is a brief structural diagram of the thermodynamic power conversion system (note: the shape shown in the attached drawing is not the actual shape, and is only used to facilitate the understanding of the working process of the conversion system): 1 and 9 are closed containers connected to each other; 2 and 6 are closed valves; 3 is a bias positioning device; 4 is a bearing; 5 is a pipe; 7 is a bracket; 8 is a working fluid; 10, 11 are relatively independent saturated steam; The core component of thermoelectric power conversion. Now briefly describe its temperature difference power conversion process as shown in the accompanying drawings, when the two containers of 1 and 9 have no temperature difference, the working medium is in a static state in the 9 container. When heating the container 9, the heat is transferred to the working fluid 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com