Optical lens zoom drive mechanism of stage lamp

A technology of optical lens and transmission mechanism, which is applied in the field of stage lights, can solve the problems of not being able to meet customers' quiet requirements, affect the use effect, and high maintenance costs, and achieve the effects of low noise, convenient adjustment, and low maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

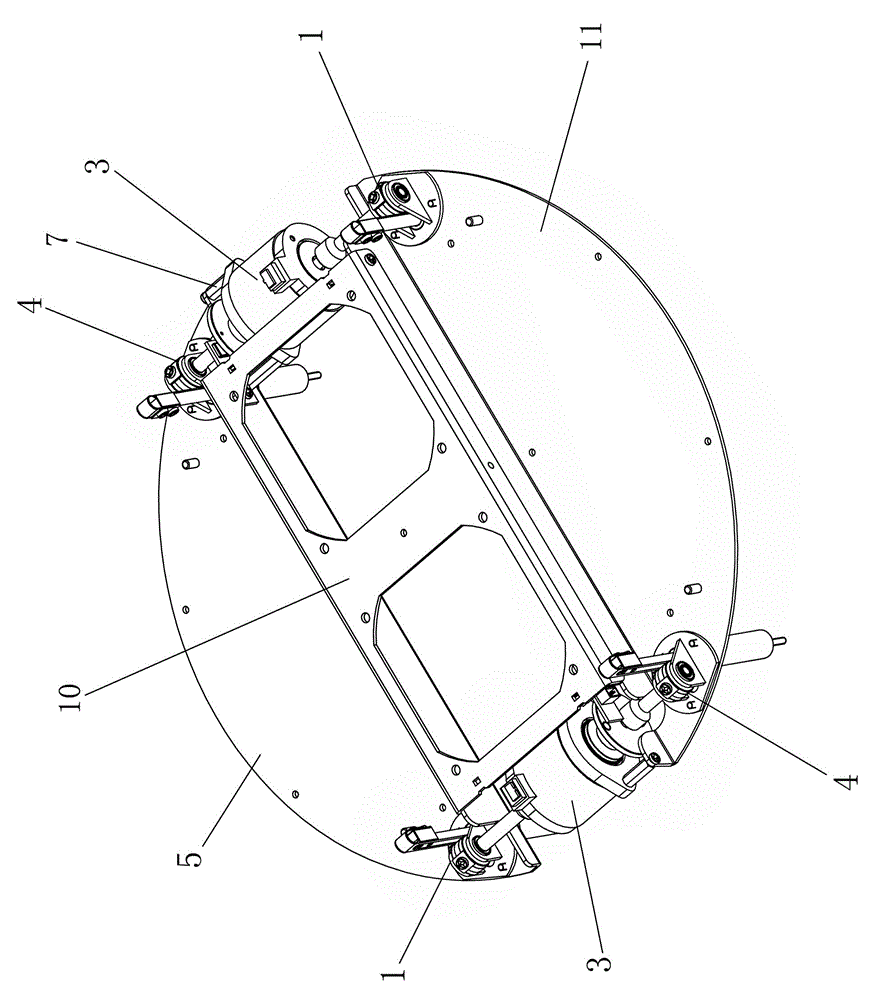

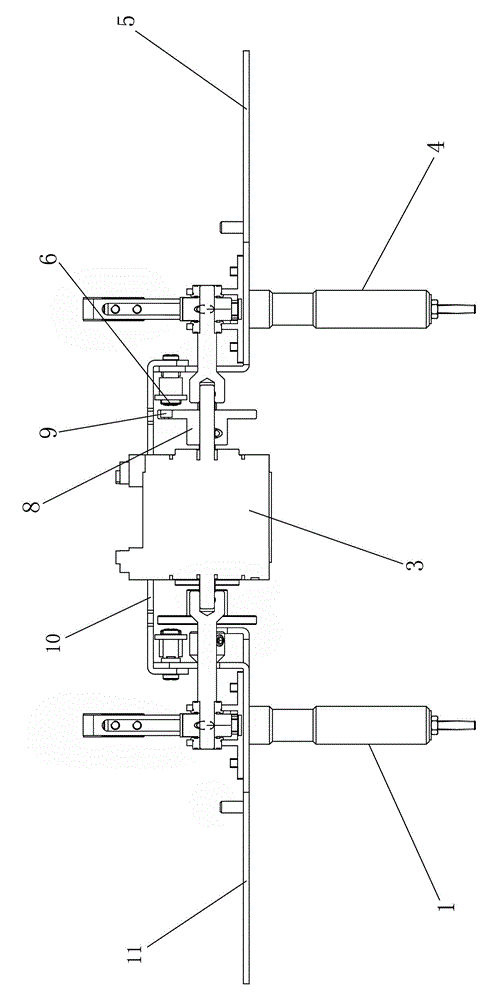

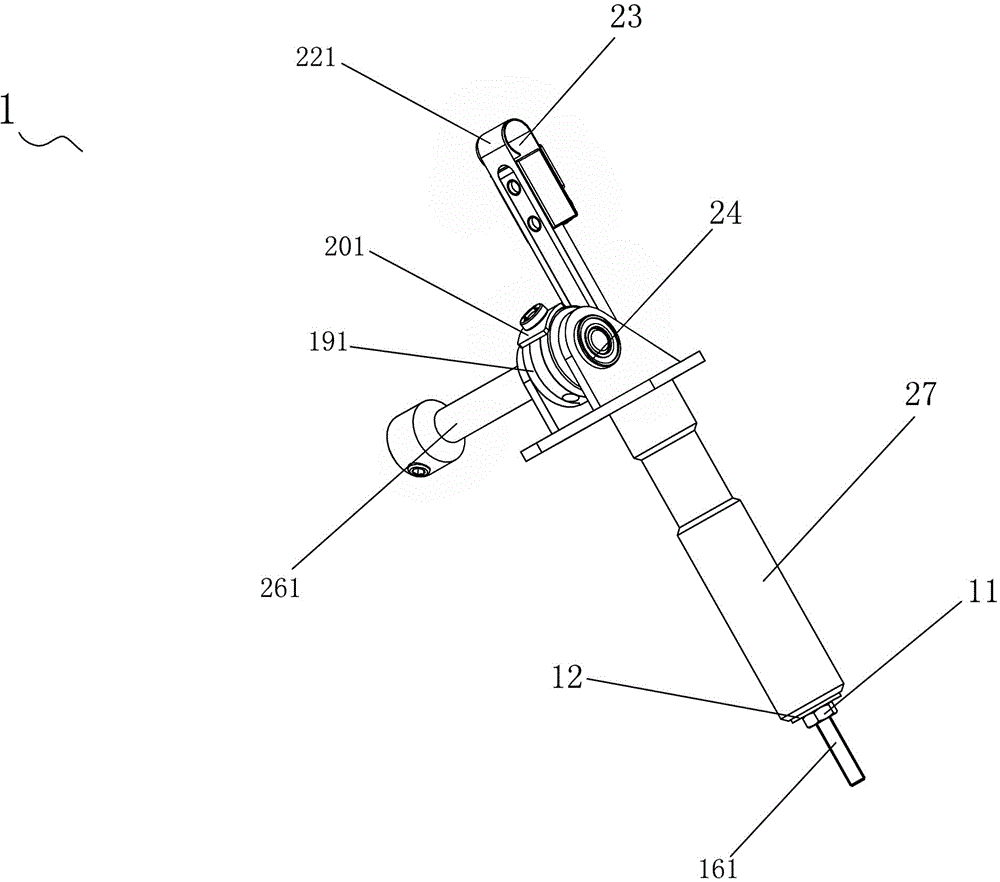

[0019] Such as figure 1 , figure 2 As shown, an optical lens zooming transmission mechanism of a stage lamp comprises a left fixed plate 5 and a right fixed plate 11, and the left fixed plate 5 and the right fixed plate 11 are connected by a fixed reinforcing plate 10; the structure of the right fixed plate 11 It is symmetrical to the structure of the left fixed plate 5; the left and right sides of the left fixed plate 5 are respectively connected with the left linear transmission mechanism 1 and the right linear transmission mechanism 4; the left and right sides of the right fixed plate 11 are respectively connected with the right linear transmission mechanism 4 and the left linear transmission mechanism The transmission mechanism 1; the left linear transmission mechanism 1 and the right linear transmission mechanism 4 are respectively connected with the biaxial stepping motor 3; the biaxial stepping motor 3 is connected to the left fixed plate 5 through the hexagonal column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com