External ultrasonic level gauge with sound velocity self-calibration function and measuring method thereof

An ultrasonic and self-calibration technology, which is applied in the direction of liquid/fluid solid measurement, measuring devices, liquid level indicators, etc., can solve the problem of low measurement accuracy, low liquid level measurement accuracy, and measurement accuracy less than 1mm level, etc. problems, to achieve the effect of reducing environmental interference, stable and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

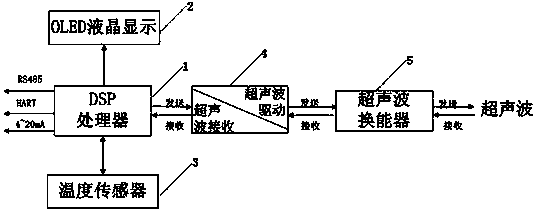

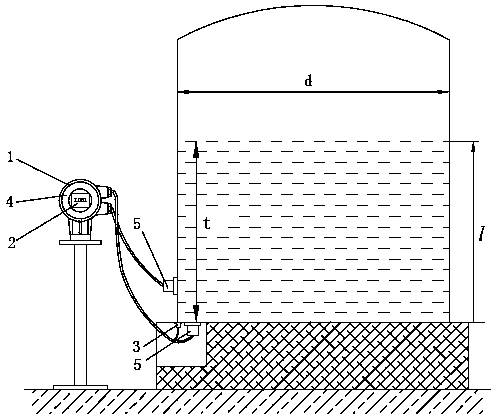

[0022] see figure 1 , 2 , an external ultrasonic liquid level gauge with sound velocity self-calibration function, including DSP processor 1 connected to OLED display 2, DSP processor 1 connected to temperature sensor 3, temperature sensor 3 connected to the measured storage tank, DSP processor 1 It is connected with the ultrasonic driving and receiving module 4, and the ultrasonic driving and receiving module 4 is connected with the storage tank under test through the ultrasonic transducer 5.

[0023] There are two ultrasonic transducers 5 , one is a measuring probe for sending and receiving ultrasonic waves, and the other is a calibration probe for self-calibrating reference sound velocity. The invention adopts a liquid-mediated installation and measurement method, which can effectively reduce environmental interference, and can modify ultrasonic emission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com