Tension-torsion composite clamp under multi-physics coupling condition

A multi-physics and fixture technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of unusable testing, testing material mechanical properties, low cost, etc., to achieve reliable work, Strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

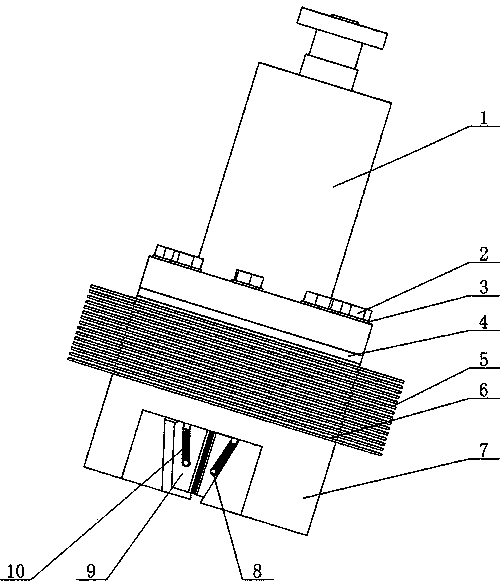

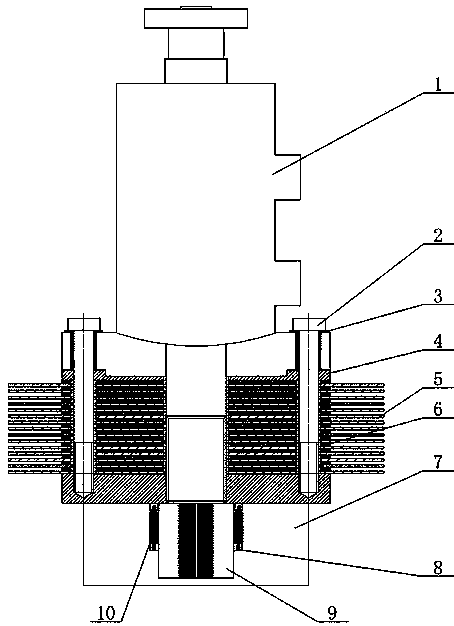

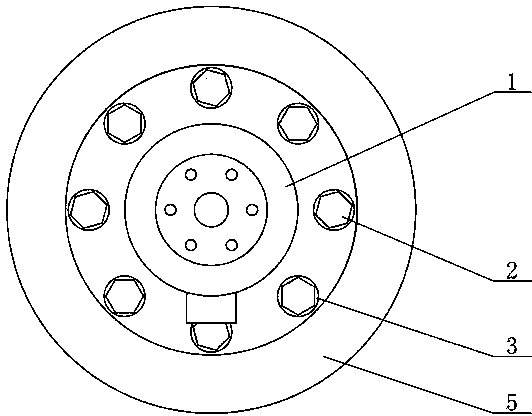

[0019] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1 to Figure 6 As shown, the tension-twist compound clamp applicable to multi-physical field coupling conditions of the present invention includes a constant velocity hydraulic cylinder 1, an insulating part, a heat insulating part, and a clamping part. The rear end of the constant velocity hydraulic cylinder 1 passes through the The flange is connected with the tensile torsion composite sensor and installed on the testing machine. The rear end of the flange is a stepped shaft, leaving a wrench space for screw assembly; the constant velocity hydraulic cylinder 1 is installed on the positioning piece 4 through the front flange branch, and the positioning piece 4. Next to the heat insulation part, the lower part of the heat insulation part is the clamping part; the front flange of the constant velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com