Output capacitance voltage-sharing control system and control method for three-level DC converter

A technology of DC converters and output capacitors, which is applied in the field of DC converters and output capacitor voltage equalization devices of DC converters. Reduced pressure margin, reduced distortion, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

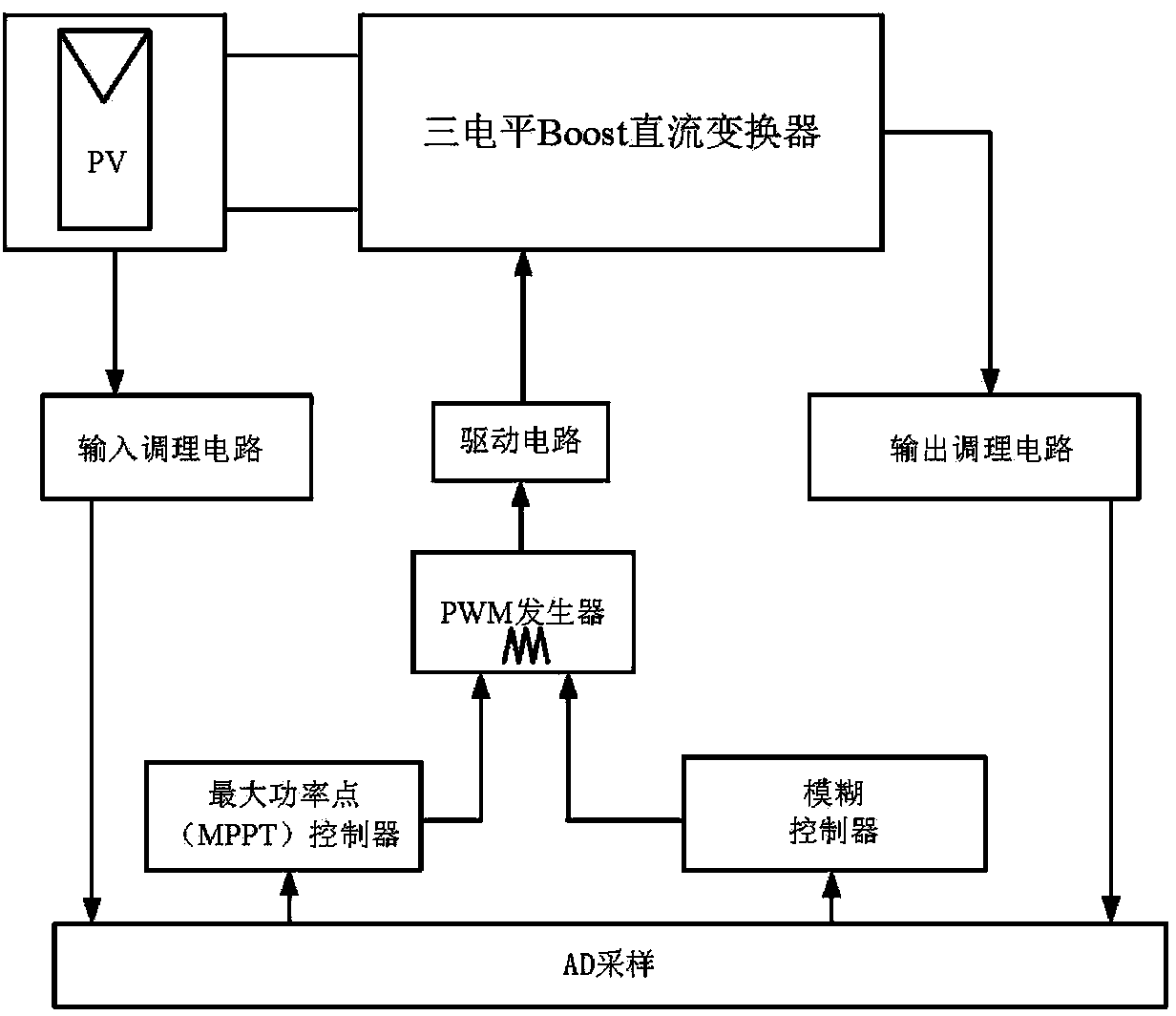

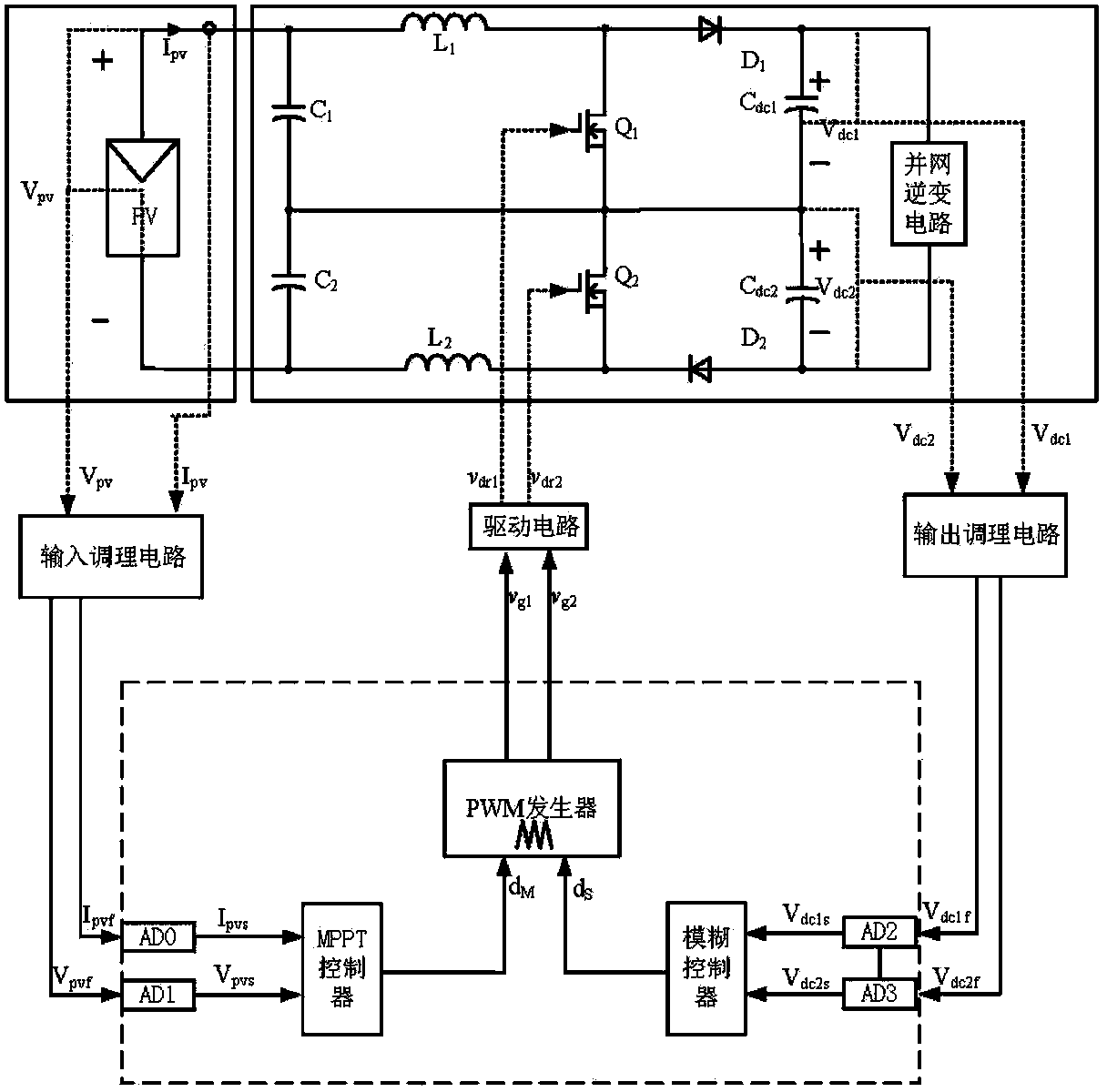

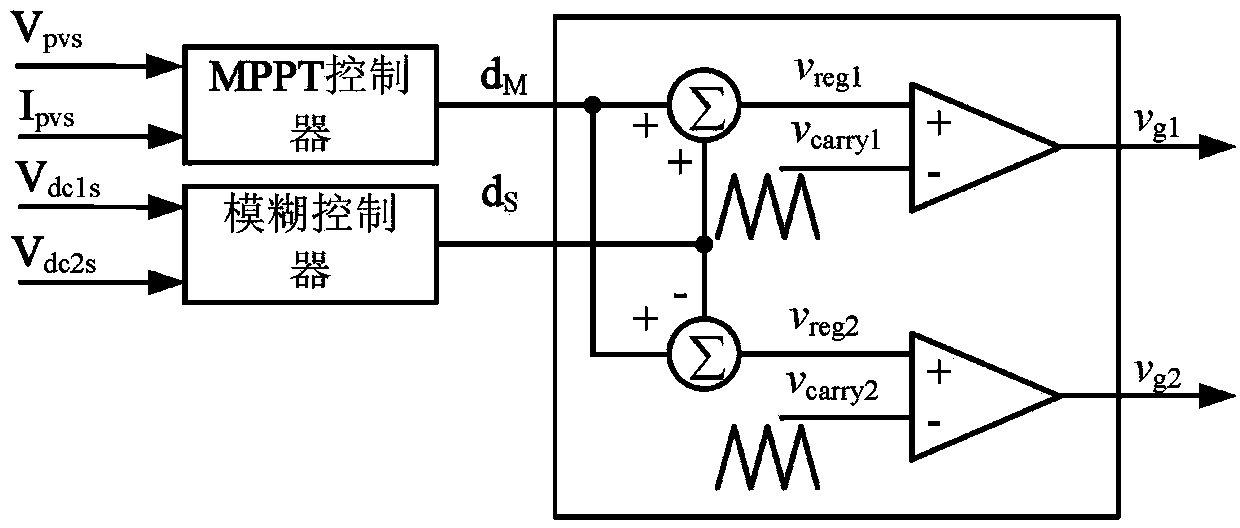

[0033] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes: three-level Boost DC converter, drive circuit, input conditioning circuit, output conditioning circuit, AD sampling unit, PWM generator, MPPT controller, fuzzy controller, PV analog power supply, digital control chip, Among them, the AD sampling unit, PWM generator, MPPT controller and fuzzy controller are implemented by software programming in the digital control chip, that is, digital control strategy.

[0034] The input voltage V of the three-level Boost DC converter pv and the input current signal I pv The signal quantity V is obtained through the input conditioning circuit pvf and I pvf Sent to the AD sampling unit, the obtained sampling value V pvs and I pvs As the input of MPPT controller 7; output capacitor voltage signal V dc1 and V dc2 The signal quantity V is obtained through the output conditioning circuit dc1f and V dc2f Sent to the AD sampling unit, the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com