Method for preparing chilli sauce and chilli sauce

A production method and technology of chili sauce, which is applied in the food field, can solve the problems of not being able to meet people's taste needs and single raw materials of chili sauce, and achieve the effects of short production cycle, long shelf life and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

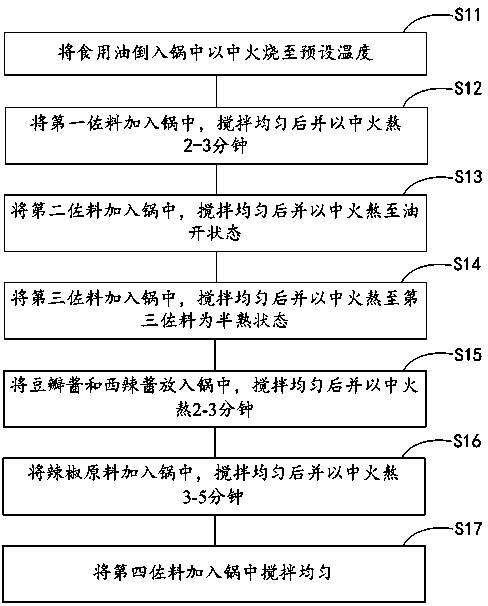

Image

Examples

example 1

[0040] First pour 500g of edible oil into the pot and heat it to 80 degrees; then add the first condiment consisting of 7.5g of fragrant fruit, 7.5g of grass fruit, 2g of clove, 3g of star anise, 7.5g of cinnamon, 6g of amomum and 5g of bay leaf Add it into the pot, stir it evenly, and boil it with medium heat for 2.5 minutes, at this time, the fragrance of the first condiment will evaporate; then add fennel 7.5g, cumin 7.5g, cumin 7.5g and comfrey 1g Add the second condiment into the pot, stir well and boil over medium heat until the oil boils; then add the third condiment consisting of 250g minced ginger and 250g minced garlic into the pot, stir well and simmer over medium heat until The third condiment is in a half-cooked state; then put 50g of bean paste and 50g of hot pepper sauce into the pot, stir evenly and cook for 3 minutes on medium heat; then add 50g of dry chili noodles with a general spicy taste into the pot , stir well and boil for 5 minutes on medium heat; fina...

example 2

[0043] First pour 600g of edible oil into the pot and heat it to 85 degrees; then add the first condiment consisting of 8g of fragrant fruit, 7g of grass fruit, 3g of clove, 3.5g of star anise, 7g of cinnamon, 6.5g of amomum and 5.5g of fragrant leaves Add it into the pot, stir it evenly, and boil it with medium heat for 3 minutes, at this time, the fragrance of the first condiment will evaporate; then add the second seasoning consisting of 7 g of anise, 7 g of cumin, 8 g of cumin and 1 g of comfrey. Add seasonings into the pot, stir well and boil over medium heat until the oil boils; then add the third seasoning consisting of 300g minced ginger and 300g minced garlic into the pot, stir well and boil over medium heat until the third seasoning The three condiments are in a half-cooked state; then put 80g of bean paste and 80g of hot pepper sauce into the pot, stir well and cook on medium heat for 2.5 minutes; then add 100g of spicy chili cubes into the pot, stir well And simmer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com