An automatic detection device

An automatic detection device and detection device technology, applied in the field of machinery, can solve the problems of large eye damage to workers, failure to provide details, slow time consumption, etc., and achieve the effects of low cost, convenient management, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

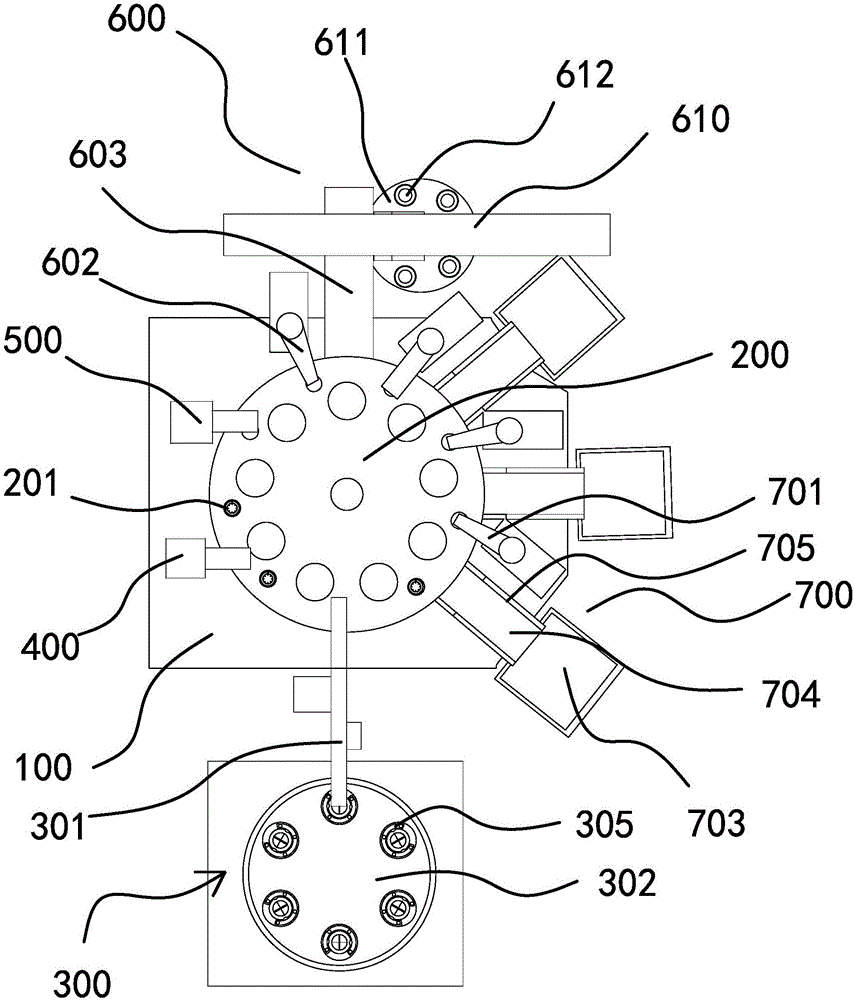

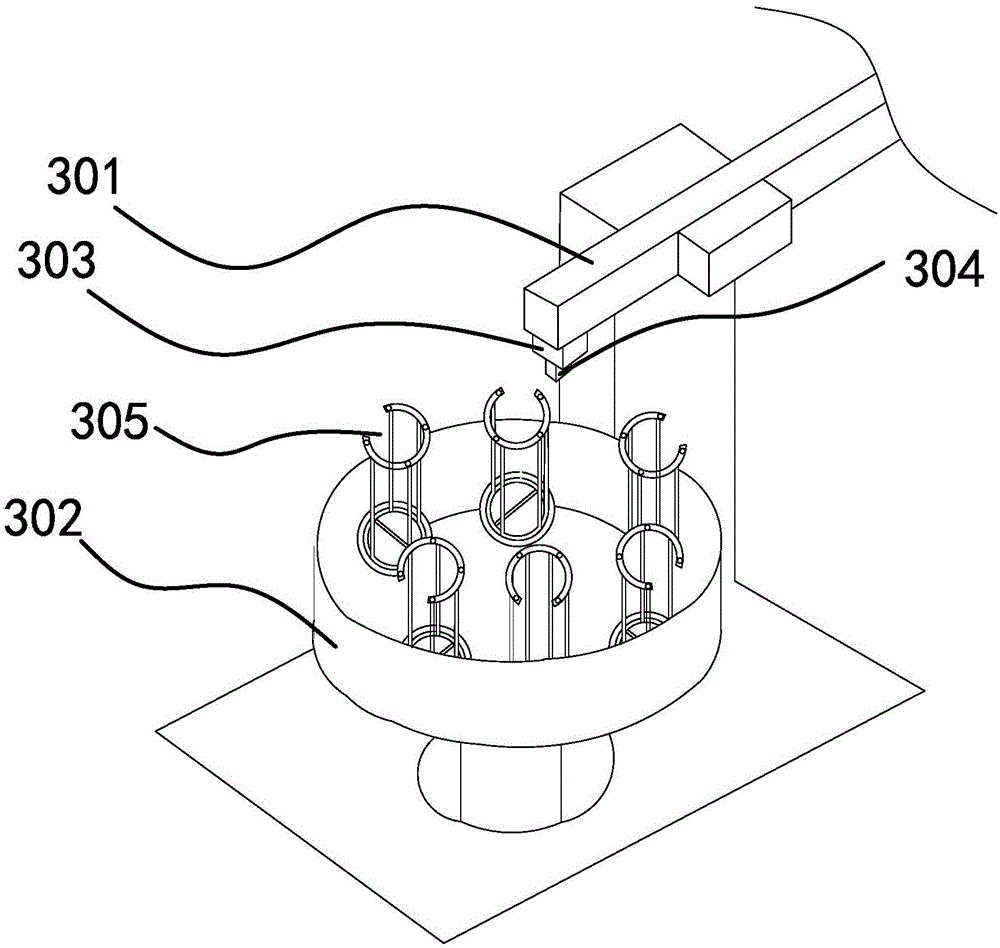

[0036] Such as figure 1 As shown, the automatic detection device includes a frame 100 and a turntable 200 arranged on the frame 100, and the frame 100 is provided with a feeding device 300, a first detection device 400, and a second detection device that surround the turntable 200 in turn. The device 500, the qualified product receiving device 600 and the defective product receiving device 700.

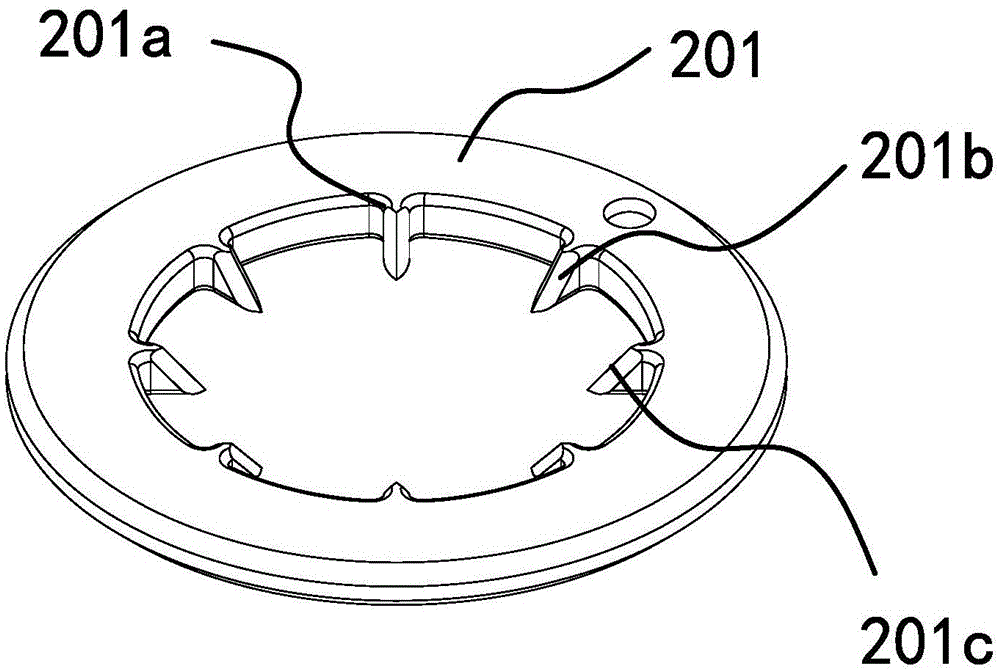

[0037] Such as figure 2 As shown, a plurality of uniformly distributed and annular reference plates 201 are installed on the turntable 200, a positioning block 201a is formed extending radially on the inner wall of the reference plate 201, and a positioning block 201a is formed at the outer end. From the upper surface of the reference plate 201 to the lower surface of the reference plate 201, the inclined portion 201b is gradually inclined downward. The inclined portion 201b is composed of a plane and two intersecting inclined surfaces, and the intersection of the two inclined surfa...

Embodiment 2

[0078] Such as Figure 13 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the recovery assembly includes a recovery disc 706, a mounting column 707, and a plurality of columns 708 surrounding the upper end surface of the recovery disc 706, The recovery disc 706 has a through hole through which the installation column 707 passes. The recovery disc 706 is rotatably mounted on the installation column 707. When the turntable 200 carries the detected defective workpiece and moves to the corresponding position of the grabbing assembly, The grabbing component grabs the defective workpiece and puts the defective workpiece into the corresponding column 708. The defective workpiece is sleeved on the column 708. After the defective workpieces on a row of column 708 are collected, the recycling disc 706 can be artificially rotated. , so that the empty column 708 is moved to a position corresponding to the grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com