A continuous manufacturing machine for foam concrete insulation boards for construction

A foamed concrete and thermal insulation board technology, applied in the direction of manufacturing tools, supply devices, pressing rollers, etc., can solve the problems of low degree of production automation, high labor intensity of workers, and large use of molds, etc., to achieve high degree of equipment automation and reduce labor. Strength, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, "longitudinal" is the direction parallel to the guide rail of the undercarriage part of the guide rail, and the transverse direction is the direction perpendicular to the guide rail of the undercarriage part of the guide rail

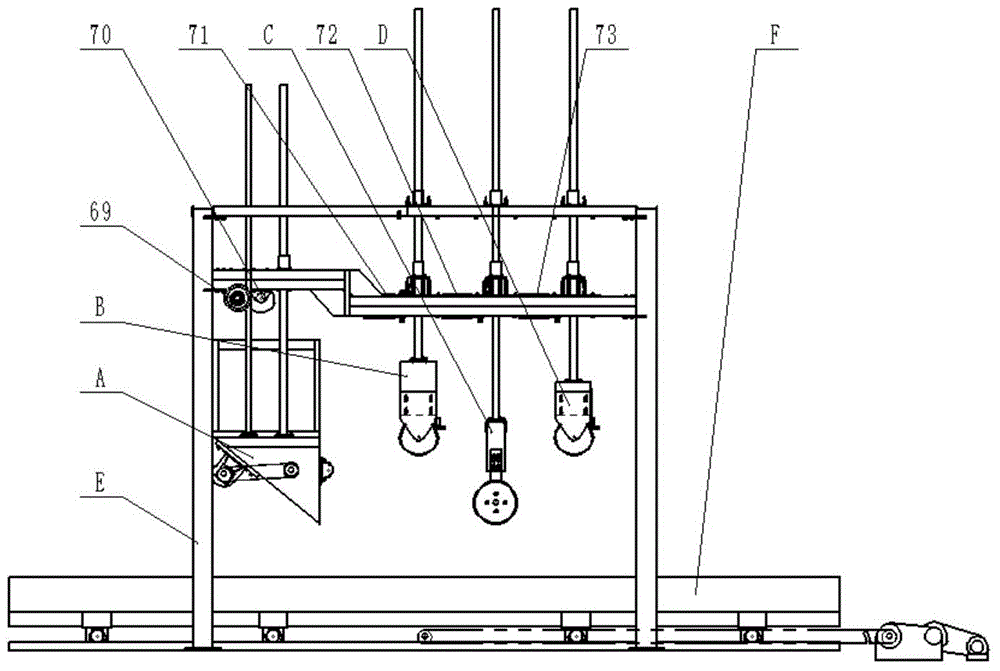

[0037] This embodiment provides a continuous manufacturing machine for thermal insulation boards for buildings, including a frame body part E, a hopper assembly part A installed on the frame body part, a lower pressure roller assembly part B, a middle pressure roller assembly part C, and an upper pressure roller assembly part. Part D, guide rail bottom car assembly part F; the overall assembly schematic diagram is as follows figure 1 as shown,

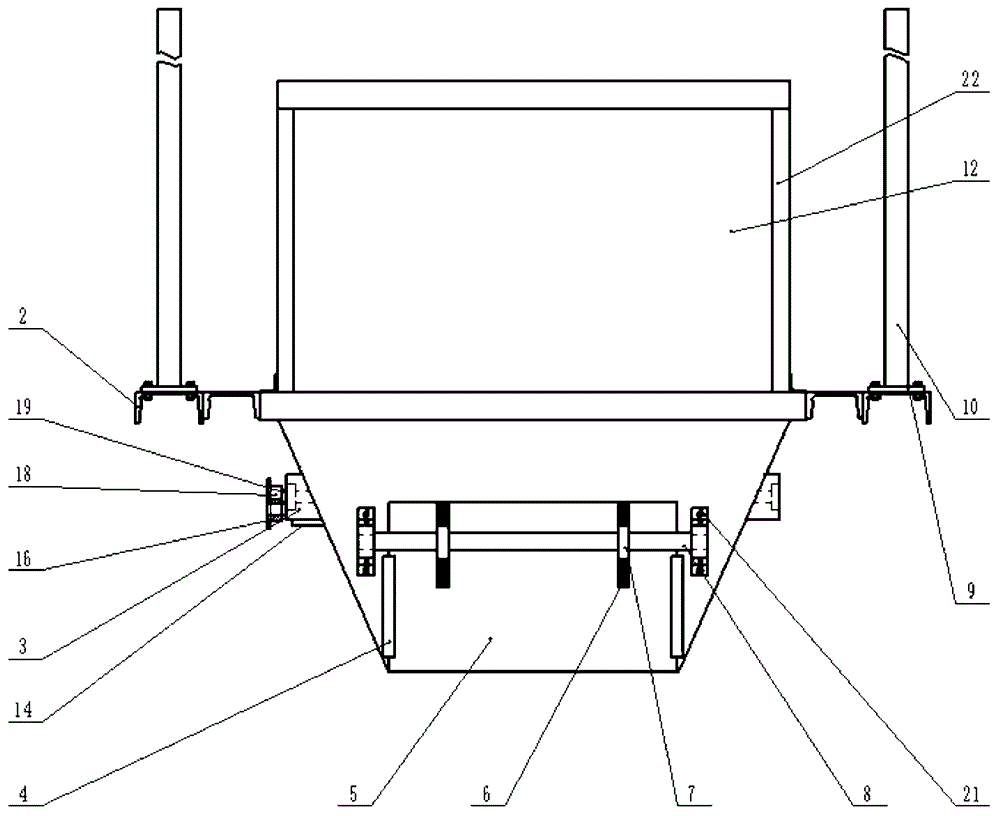

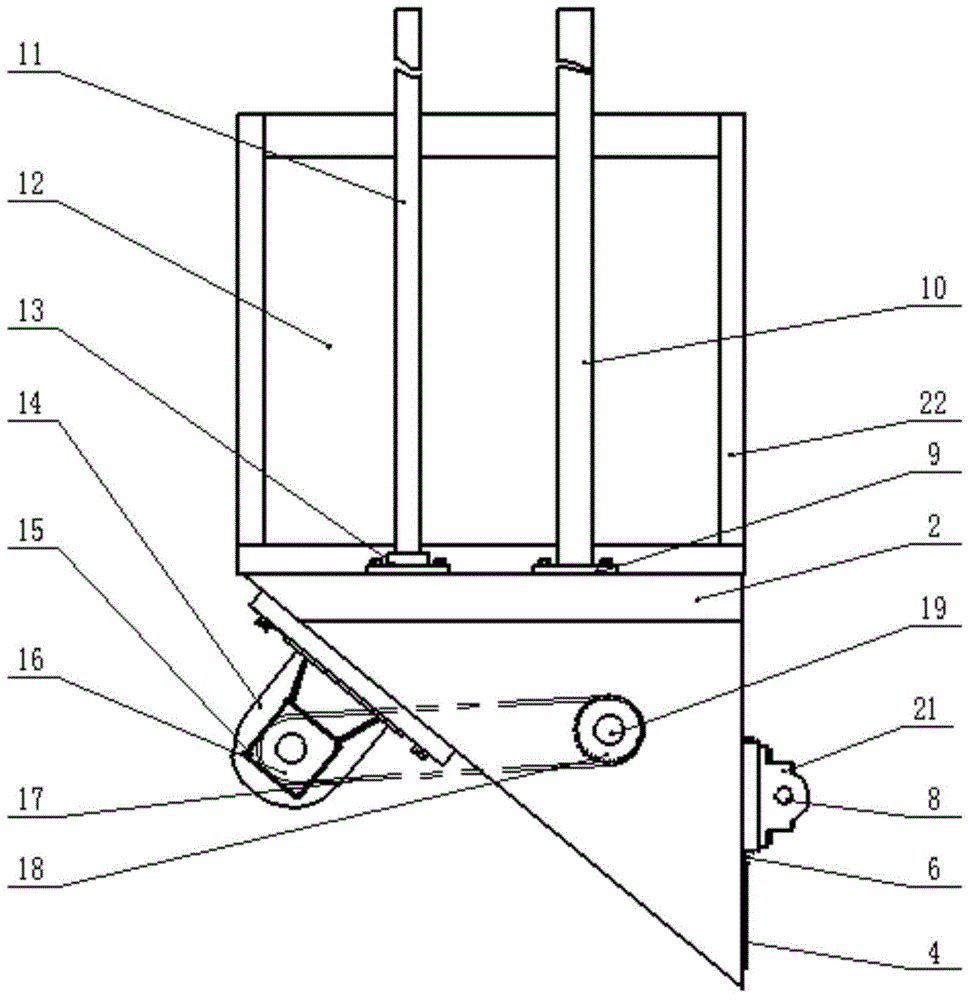

[0038] The overall assembly diagram is as figure 1 As shown, the assembly diagram of other parts is shown in Figure 2-Figure 12 shown.

[0039] The schematic diagram of the assembly structure of the frame part E and its assembly relationship with other parts are as follows: Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com